Polyethylene breathing paper

Product Description

Breathing paper (also known as waterproof breathable film, Dike waterproof breathable film) is a functional film made of polymer materials (such as polyethylene, polytetrafluoroethylene, etc.), and the surface is distributed with micropore structure with a diameter of about 0.0004 micron. Its working principle is based on microporous filtration and concentration gradient diffusion: Waterproof: the diameter of liquid water droplets (about 0.02 mm) is much larger than that of micropores, so it cannot penetrate; Permeability: The molecular diameter of water vapor (about 0.0000004 mm) is much smaller than that of micropores, and it can diffuse freely. Some high-end products (such as Dupont Tyvek) use flash evaporation process to form non-woven fabric structure through high-density polyethylene fibers, which has both the toughness of paper and the waterproof of film. application area building field Exterior wall and roof: as the second waterproof barrier, protect the insulation layer (such as metal roof and wood structure building); Energy-saving design: reduce air infiltration and energy consumption (reduce heat loss in cold areas and block hot air intrusion in hot areas). Industry and medical treatment Medical packaging: sterilized packaging (such as sterile masks and surgical instruments), which uses one-way air permeability to balance sterilization and pollution prevention; Chemical protection: resistant to acid and alkali corrosion, used in chemical plants and sewage treatment facilities. Outdoor and consumption Equipment manufacturing: backpacks, umbrellas, tents, both lightweight and durable; Clothing fabric: windproof and waterproof coat to enhance the comfort of outdoor activities.

Breathing paper (also known as waterproof breathable film, Dike waterproof breathable film) is a functional film made of polymer materials (such as polyethylene, polytetrafluoroethylene, etc.), and the surface is distributed with micropore structure with a diameter of about 0.0004 micron. Its working principle is based on microporous filtration and concentration gradient diffusion: Waterproof: the diameter of liquid water droplets (about 0.02 mm) is much larger than that of micropores, so it cannot penetrate; Permeability: The molecular diameter of water vapor (about 0.0000004 mm) is much smaller than that of micropores, and it can diffuse freely. Some high-end products (such as Dupont Tyvek) use flash evaporation process to form non-woven fabric structure through high-density polyethylene fibers, which has both the toughness of paper and the waterproof of film. application area building field Exterior wall and roof: as the second waterproof barrier, protect the insulation layer (such as metal roof and wood structure building); Energy-saving design: reduce air infiltration and energy consumption (reduce heat loss in cold areas and block hot air intrusion in hot areas). Industry and medical treatment Medical packaging: sterilized packaging (such as sterile masks and surgical instruments), which uses one-way air permeability to balance sterilization and pollution prevention; Chemical protection: resistant to acid and alkali corrosion, used in chemical plants and sewage treatment facilities. Outdoor and consumption Equipment manufacturing: backpacks, umbrellas, tents, both lightweight and durable; Clothing fabric: windproof and waterproof coat to enhance the comfort of outdoor activities.

| Payment Terms: | Prevent 30% deposit, and pay the final payment after delivery. |

| |

Product Image

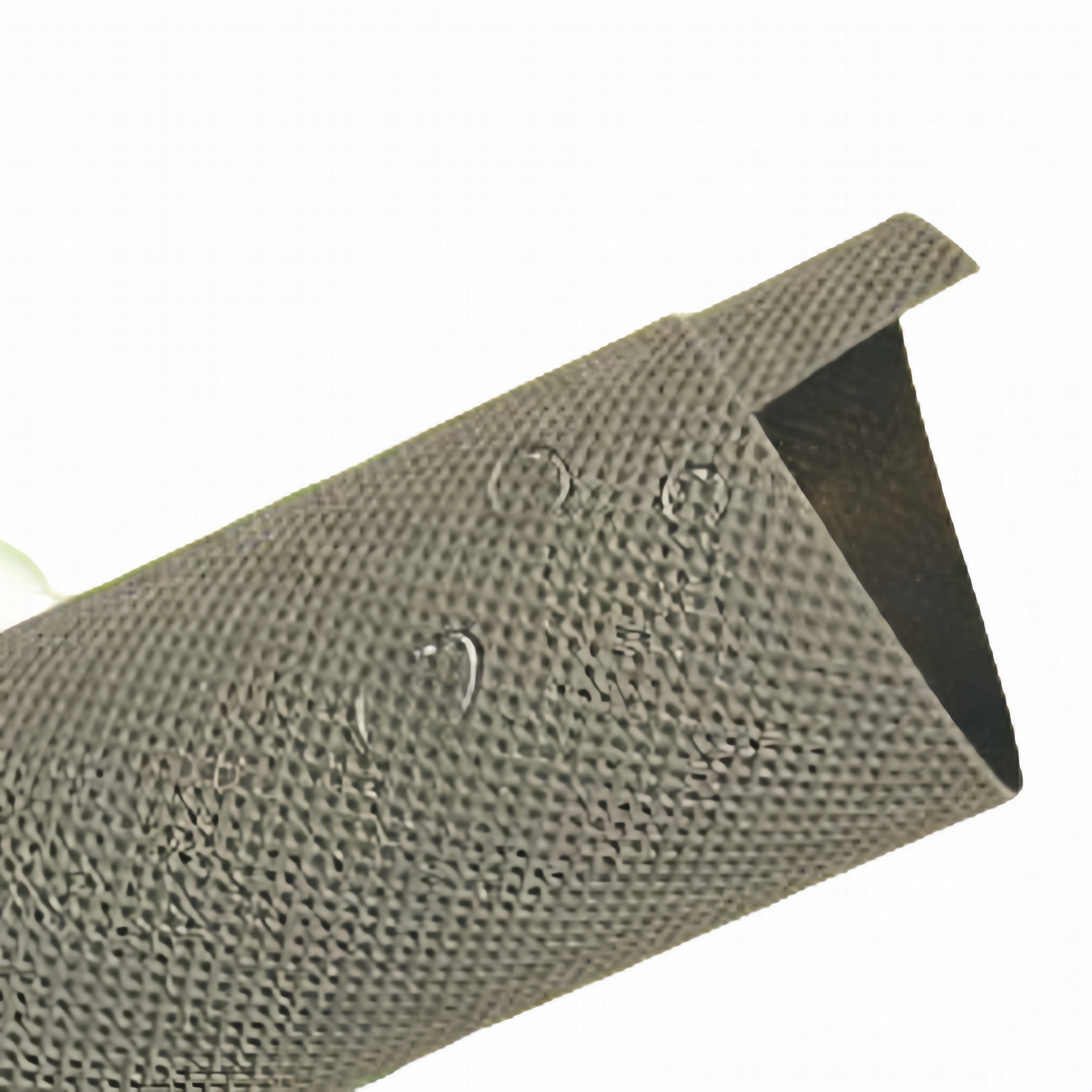

Img 1

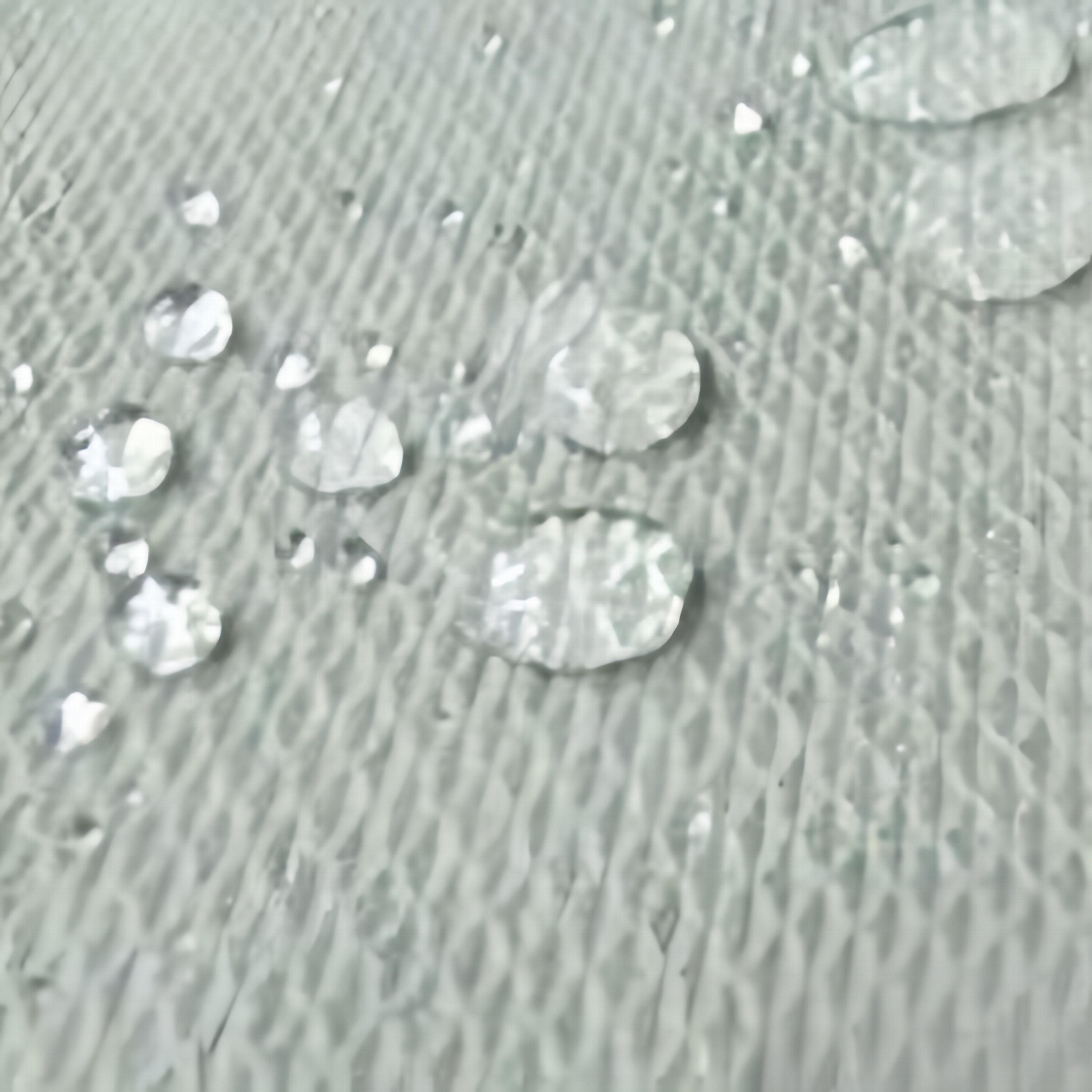

Img 2

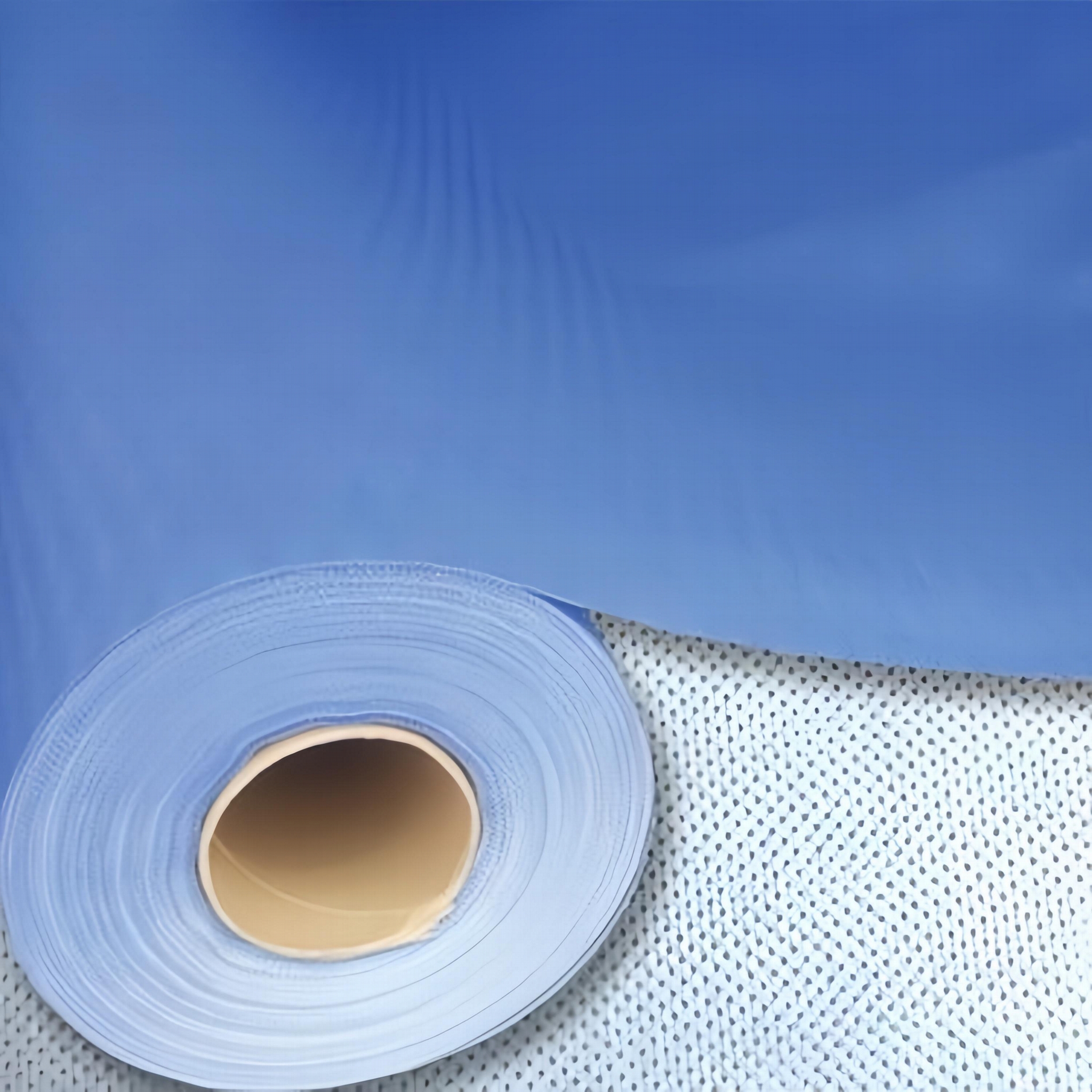

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,