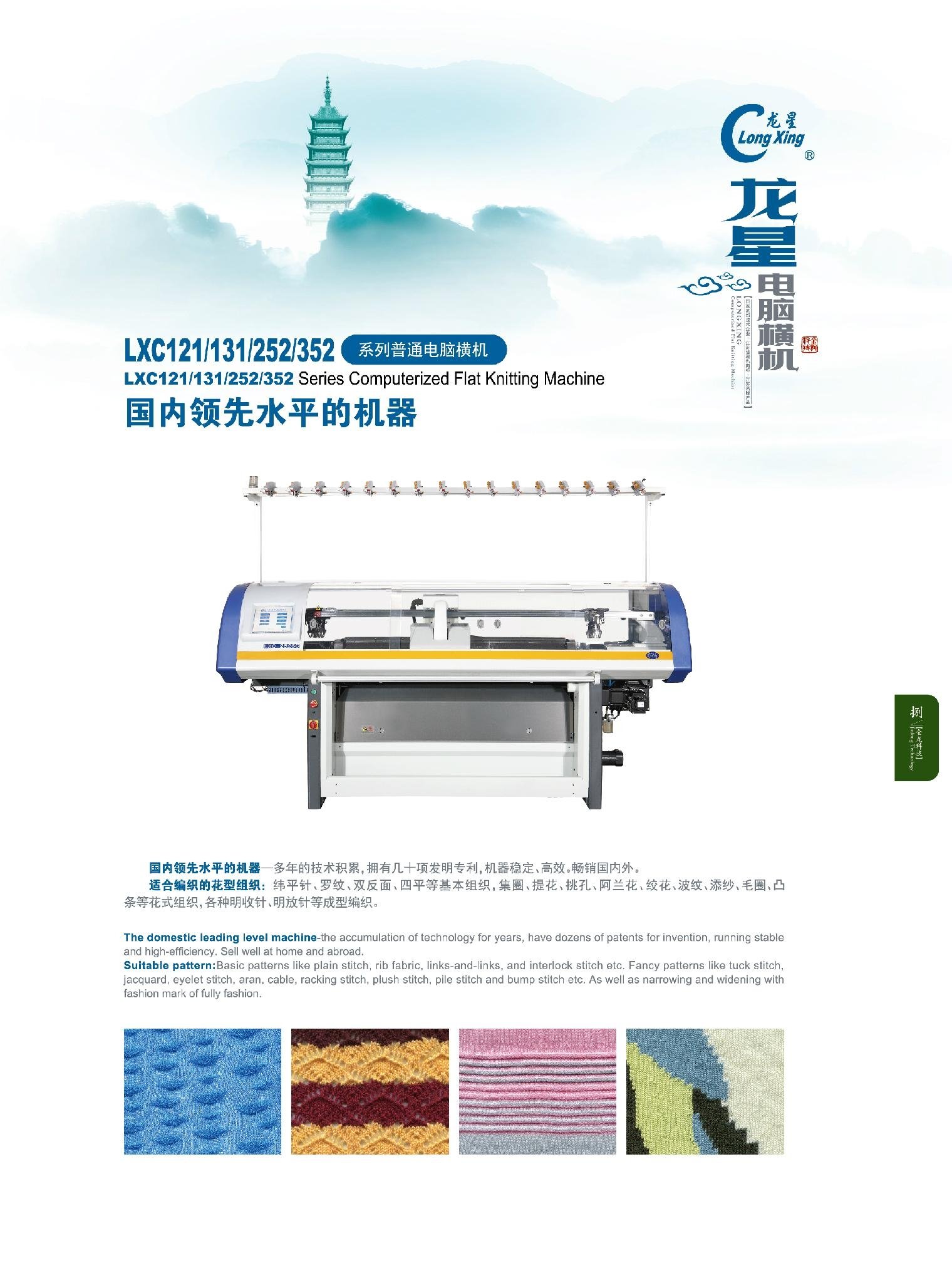

Product Description

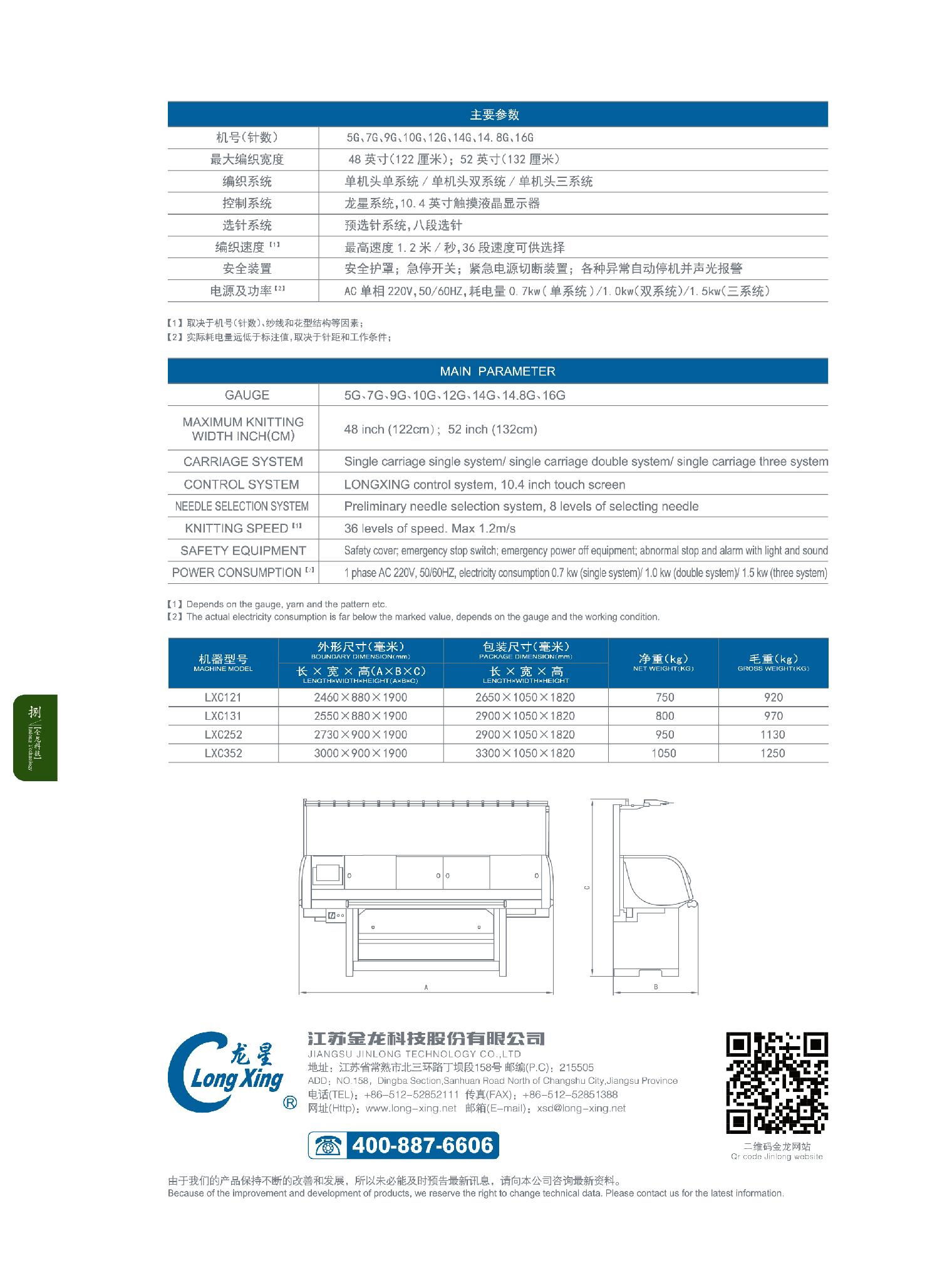

Gauge

1. Knitting width: 132cm (52inch)

2. Gauge: 3G,3.5G, 5G,7G, 8G, 9G, 10G, 12G, 14G, 14.8G, 16G, 18G

3. Needle bed: Single needle and single flake assembled needle bed, needles and flakes can be replaced when mangling.

4. Carriage: Single carriage. Double System.

5. Main drive system: Driving with AC servo motor. Variable carriage stroke according to knitting width.

6. Knitting speed: 48 levels of speed. Max 1.2m/sec.Driver by servo motor, Knitting speed varies according to gauge and knitting condition.

7. Stitch density: 48 levels of independent selections with slight adjustment on each section.

8. Various-Stitch: Various-Stitch allows individual adjustment of loose/tight stitches by program in a single knitting row.

9. Sinker: Adjustable sinker is controlled by a step motor.

10. Racking: Controlled by servo-motor. Back racking/ Double racking, Max 2-inch racking(Left 1 inch righ 1 inch).

11. Yarn carriers: 2*8 sets of yarn carriers on 4 guide bars. Plating yarn carriers and intarsia yarn carriers are optional settings.

12. Yarn supply system: 16 top tensions, large knots cause machine stop and small knots cause slow running, and friction feed wheels of high speed.

13. Cam system: Cam system combined 3-way technique. Three technical selections for knitting (knit, tuck, miss). Simultaneous transferring, front or back, independent of carriage direction.

14. Yarn cutter: Single-unit system includes 1 yarn cutter and 2 yarn grippers, both sides standards.

15. Setup device: Stable takedown comb and special setup needles

16. Needle selection: Full jacquard selection via 6 levels of special solenoid actuators.

17. Takedown device: Main/sub rollers: Changeable 48 levels, automatically adjustable on each level, automatic opening and closing.

18. Operation lamp: Green / normal operation; Yellow / normal stop; Red / abnormal stop.

19. Stop motion: Stop automatically with signal and sound alarm when yarn break, knot, press off, needle break, over current, roll back, wrong racking, improper sinker, needle collision, excessive yarn, piece count, etc.

20. Packing dimension

Weight: Length*Width *High 3m*1.1m*1.8m Net weight/Gross weight 1200/1350KG

Controller Functions

1. Data Input: USB memory interface.

2. Pattern memory:96M

3. Display screen: 10.4'LED full turch sreen.

4. Operation platform: Standard language are Chinese, English,Turkish,Korean,Italian.Spanish

5. Power: 1 phases AC 220V, 50/60Hz, electricity consumption 1.8KVA. Power supply for resuming after power failure.

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,