| Model: | ALUMINUM TUBE |

|---|---|

| Brand: | 3003, 5083,6061 ALUMINIUM TUBE |

| Origin: | - |

| Category: | Construction & Decoration / Pipe, Tube & Parts / Aluminum Tube & Pipe |

| Label: | ASTM B234 Alu Tube , ASTM B241 6061 AL , 5083 Aluminum Tube |

| Price: |

US $0.85

/ kg

|

| Min. Order: | 5 kg |

| Live Chat: | Last Online:27 Jun, 2023 |

| The following is a short breakdown of the most common grades and their general properties in order to provide you with an understanding of their many uses: | ||||||||||

|

Aluminum Tempers

"H" Temper-Non-Heat-Treatable Alloys / Strain-Hardened

H14 - Strain hardened (cold worked) without thermal treatment and 1/2 hard.

H22 - Strain hardened and partially annealed, 1/4 hard.

H32 - Strain hardened and stabilized by low temperature heating, 1/4 hard.

H34 - Strain hardened and stabilized by low temperature heating, 1/2 hard.

H111 - Applies to products which are strain-hardened less than the amount required for a controlled H11 temper.

H112 - Applies to products which acquire some temper from shaping processes not having special control over the amount of strain-hardening or thermal treatment, but for which there are mechanical property limits

H116 - Applies to products manufactured from alloys in the 5xxx series, for which the magnesium content is 3% nominal or more.

"T" Temper-Heat-Treatable-Alloys / Thermally Treated

T6 - Solution heat-treated and artificially aged. A stable temper.

T52 - Stress-relieved by compressing. Applies to products which are stress-relieved by compressing after solution heat-treatment,

T651 - Solution heat treated, stress-relieved by stretching and artificalially aged. Equivalent to T6 and applies to plate and rolled bar except 2219

T6511 - Solution heat treated, stress-relieved by stretching and artificially aged with minor straightening. Equivalent to T6 and applies to extruded rod, bar and shapes except 2024

Reference Standards:

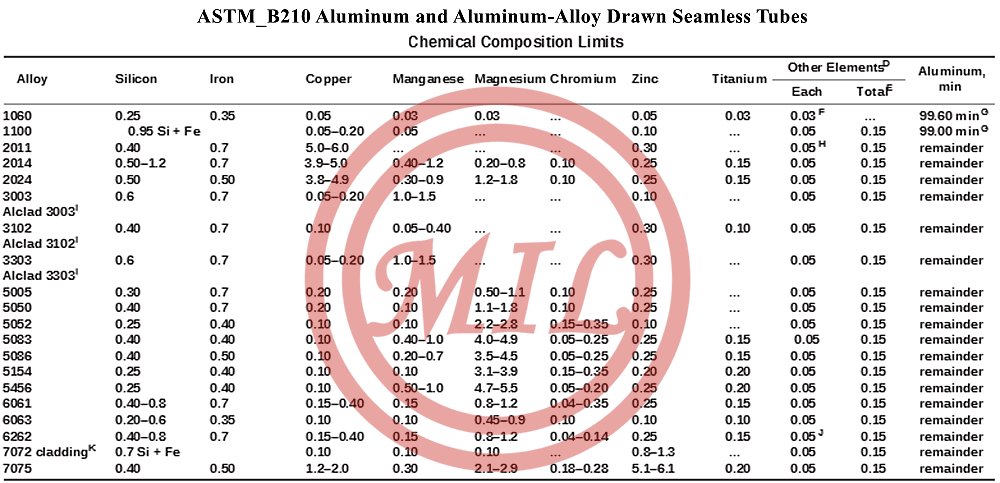

ASTM B210 Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

ASTM B221 Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

ASTM B234 Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes for Condensers and Heat Exchangers

ASTM B241 Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

ASTM B313 Standard Specification for Aluminum and Aluminum-Alloy Round Welded Tubes

ASTM B317 Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, Structural Profiles, and Profiles for Electrical Purposes (Bus Conductor)

ASTM B345 Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube for Gas and Oil Transmission and Distribution Piping Systems

ASTM B361 Standard Specification for Factory-Made Wrought Aluminum and Aluminum-Alloy Welding Fittings

ASTM B404 Standard Specification for Aluminum and Aluminum-Alloy Seamless Condenser and Heat-Exchanger Tubes with Integral Fins

ASTM B429 Standard Specification for Aluminum-Alloy Extruded Structural Pipe and Tube

ASTM B483 Standard Specification for Aluminum and Aluminum-Alloy Drawn Tube and Pipe for General Purpose Applications

ASTM B491 Standard Specification for Aluminum and Aluminum-Alloy Extruded Round Tubes for General-Purpose Applications

ASTM B547 Standard Specification for Aluminum and Aluminum-Alloy Formed and Arc-Welded Round Tube

ASTM B744 Standard Specification for Aluminum Alloy Sheet for Corrugated Aluminum Pipe

ASTM B745 Standard Specification for Corrugated Aluminum Pipe for Sewers and Drains

EN 754-7 Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 7: Seamless tubes, tolerances on dimensions and form

EN 755-7 Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 7: Seamless tubes, tolerances on dimensions and form

BS EN 755-8 Aluminium and aluminium alloys - Extruded rodbar, tube and profiles

EN 13957 Aluminium and aluminium alloys - Extruded round, coiled tube for general applications - Specification

EN 13958 Aluminium and aluminium alloys - Cold drawn round, coiled tube for general applications - Specification

EN 1592-1 Aluminium and aluminium alloys - HF seam welded tubes - Part 1: Technical conditions for inspection and delivery

EN 1592-2 Aluminium and aluminium alloys - HF seam welded tubes - Part 2: Mechanical properties

EN 1592-3 Aluminium and aluminium alloys - HF seam welded tubes - Part 3: Tolerances on dimensions and form for circular tubes

EN 1592-4 Aluminium and aluminium alloys - HF seam welded tubes - Part 4: Tolerances on dimensions and form for square, rectangular and shaped tubes

EN 2070-4 Aerospace series - Aluminium and aluminium alloy wrought products - Technical specifications - Part 4: Tube for structures

EN 2070-5 Aerospace series - Aluminium and aluminium alloy wrought products - Technical specification - Part 5: Tube used under pressure

EN 2257 Aerospace series - Circular tubes for structures in aluminium and aluminium alloys - Diameter 6 mm D 100 mm - Thickness 1 mm a 6 mm - Dimensions

EN 2258 Aerospace series - Circular tubes for fluids in aluminium and aluminium alloys - Diameter 3,2 mm ≤ D≤ 100 mm - Thickness 0,6 mm ≤ a 2,5 mm - Dimensions

EN ISO 15546 Petroleum and natural gas industries - Aluminium alloy drill pipe (ISO 15546:2002)

EN 2813- Aerospace series - Aluminium alloy AL-P6061-T6 - Drawn tube for pressure applications 0,6 mm a 12,5 mm

EN 3557 Aerospace series - Aluminium alloy AL-P6061-T4 - Drawn tube for pressure applications 0,6 mm a 3,0 mm

EN 60614-2-7 Draft IEC 614-2-7: Conduits for electrical installations - Specification - Part 2: Particular specifications for conduits - Section 7: Rigid non-threadable conduits of aluminium alloy

JIS H4080 Aluminium and aluminium alloys extruded tubes and cold-drawn tubes

JIS H4090 Aluminium and aluminium alloy welded pipes and tubes

JIS H4090 AMD 1-2006 Aluminium and aluminium alloy welded pipes and tubes (Amendment 1)

NF A50-616 Aluminium and aluminium alloys. Cold drawn rod/bar and tube. Part 7 : seamless tubes, tolerances on dimensions and form.

NF A50-617 ALUMINIUM AND ALUMINIUM ALLOYS. COLD DRAWN ROD/BAR AND TUBE. PART 8 : PORTHOLE TUBES, TOLERANCES ON DIMENSIONS AND FORM. (EUROPEAN STANDARD EN 754-8).)

NF A50-620 Aluminium and aluminium alloys - Cold drawn, round, coiled tube for general applications

NF A50-636-1999 (Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Part 7 : seamless tubes, tolerances on dimensions and form.)

NF A50-637-1998 (ALUMINIUM AND ALUMINIUM ALLOYS. EXTRUDED ROD/BAR, TUBE AND PROFILES. PART 8 : PORTHOLE TUBES, TOLERANCES ON DIMENSIONS AND FORM. (EUROPEAN STANDARD EN 755-8).)

NF A50-638-9 Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 9 : profiles, tolerances on dimensions and form.)

NF A50-645 Aluminium and aluminium alloys - Extruded round, coiled tube for general applications

NF A50-802 ALUMINIUM AND ALUMINIUM ALLOYS. LARGE DIAMETER WELDED TUBES. DIMENSIONS AND TOLERANCES.)

NF L10-600-4 AEROSPACE SERIES. ALUMINIUM AND ALUMINIUM ALLOY WROUGHT PROUDCTS. TECHNICAL SPECIFICATION. PART 4 : TUBE FOR STRUCTURES. (EUROPEAN STANDARD EN 2070-4).)

NF L10-600-5 AEROSPACE SERIES. ALUMINIUM AND ALUMINIUM ALLOY WROUGHT PRODUCTS. TECHNICAL SPECIFICATION. PART 5 : TUBE USED UNDER PRESSURE. (EUROPEAN STANDARD EN 2070-5).)

NF L15-611 DRAWN TUBES OF CIRCULAR SECTION IN ALUMINIUM ALLOYS. COMMON TOLERANCES.

NF L15-612 DRAWN TUBES OF CIRCULAR SECTION IN ALUMINIUM ALLOYS. PRECISION TUBES.

NF L15-640 SQUARE DRAWN TUBES IN ALUMINIUM ALLOYS.

NF L15-641 RECTANGULAR DRAWN TUBES IN ALUMINIUM ALLOYS.

NF L15-650 Aerospace series. Circular tubes for structures in aluminium and aluminium alloys. Diameter 6 mm inferior or equal to D inferior or equal to 100 mm. Thickness 1 mm inferior or equal to a inferior or equal to 6 mm. Dimensions.

NF L15-651 Aerospace series. Circular tubes for fluids in aluminium and aluminium alloys. Diameter 3,2 mm inferior or equal to D inferior or equal to 100 mm. Thickness 0,6 mm inferior or equal to a inferior or equal to 2,5 mm. Dimensions.

NF L15-660 TORPEDO-SHAPED TUBES IN ALUMINIUM ALLOYS.

NF L31-613 AEROSPACE SERIES. COLLARS,ALUMINIUM ALLOY. (EUROPEAN STANDARD EN 2365).