| Model: | - |

|---|---|

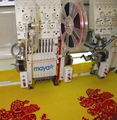

| Brand: | Mayastar |

| Origin: | Made In China |

| Category: | Industrial Supplies / Textile Machinery Parts |

| Label: | Quilting Machine , embroidery machine , Chenille embroidery |

| Price: |

-

|

| Min. Order: | 1 pc |

| Live Chat: | Last Online:09 Jun, 2014 |

Relying on more than 20 years experiences in this quilting field, we can provide u the best quality quilting machine. Our quilting machine adopts most advanced quilting machine computer control system; lowest thread breakage and best quilting stitch effect to ensure beautiful quilting result.

This series quilting machine is controlled by computer, it is mainly applied to the making of garment, leaning cushion, bedding cover, matters, sofa products, air conditioning quilt, hand bag and sleeping sacks etc. It can quilt for u very colorful patterns, for example: flower, straight line, circle pattern. The main using industries are the garment industry, hand craft industry, indoor decoration and so on.

Mayastar QM Series Computerized Shuttle Quilting Machines adopt the most advanced European computerized quilting machine technology of the world. It has been highly praise by the customers. The main spare parts of this series machines are provided by the world famous suppliers, it has reliable features and wide usage. We will provide u hundreds of patterns designs for the customer selection, and we can make unlimited original design to meet with the different users’ requirements.

And because of adopting the advanced computer system that produced by ourselves and newest techniques settings, modern patterns management and editing function, the whole machine features to be greatly improved. What’s more, Our computer controlling system have perfect self-checking and safeguard function and self-diagnosing ability under system fault of phase lack, overheat, positive stop, main shaft locking, power off and emergency stop and so on.

Mayastar QM series quilting machine can precisely sew out 360 degrees complicated patterns, and through simple and easy programming system it can sew out for u any complicated designs. For example: panel quilts with few needles big patterns with filled areas • jump patterns (option function), fine embroidery, signatures, trademark, etc.

We have double needle row quilting machine and triple needle row quilting machine, double needle row quilting machine can make the patterns of 6inches (15cm), and triple needle row quilting machine can make the patterns of 10 inches (25cm). The Max. Quilt Thickness (non-compressed foam + polyester wadding) is 40mm.

10#, 7# shuttle can be used on the machine. 7# shuttle can make much precise patterns, suitable for garment factory selecting. It can bear 60m long thread. And 10# shuttle is mainly used for bedding products. And 10# can bear the thread of 90m long

130D or 200D thread can be used on our machine. And machine working speed is 400rpm- 600rpm.

Main functions:

●Extreme precision with 360º intricate patterns

●Producing many kinds of sewing patterns such as: panel quilts with few needles • patterns with filled areas • jump patterns• fine embroidery, signatures, trademark, etc.

●Unique upper creel design makes it very easy to exchange upper thread. The operator can finish it conveniently in front of the machine, no need any climbing equipment.

●Unique adjustable (0~40mm) active roll feeding system can adjust ideally materials of different thickness and allow perfect sewing without skipped stitches on very thick (or very thin) materials and exotic “puff” effects without destroying materials.

●Unique shuttle holder design makes every stitch more precise and reliable.

●Unique automatic tension-damp system on passive feeding (adjustable) ensures perfectly the more equal & reliable material feeding and more convenient operation.

●Unique “dot” presser system allows the reduction of resistance on presser-plate when quilting very thick materials and makes every stitch trace clear and compact with distinct third dimension (without loose thread).

●Up-to-date overall design has not only beautiful appearance but also perfect safeguard, which makes the operation more safe and reliable.

●It allows the cloth to move forward and backward at low or high speed.

Other Functions:

1.Saddles and rollers driven by Panasonic servo motor ;

2.The revolution of the spindle controlled by Panasonic frequency conversion control devices.

3.Large number of built-in quilting patterns for your choice.

4.Easy and quick make new designs

5.stitches between 2mm-6mm adjustable

6.Function of pattern compensation, an effective solution to the distortion of patterns when quilting thick materials.

7.Simulation display of quilting.

8.Automatic needle raising and location brake system.

9.Function of automatic stop on breaking of thread(optional)

10.Lowest thread breakage.

11.Latest computer control system ensures precision and speed.

12.Built-in quilting punching software.

13.Running parts made by aluminum wearing and looks fantastic.

14.Shuttle size at your choice.

15.Best service online.

16.Can do cotton thread without thread breakage.

17.No need oil cam.

18.Water proof. Dust Proof structure. No oiling needed for cams!

19.Lasting life for 10 years or more!

Main Features:

MEMORY BACKUP: Automatically save the pattern memory against machine power cut or power off, newly switch one the power; the machine will continue the sewing work

Designs zoom in and zoom out function: Design can be zoon in or zoom out easily in any way, and rotating patterns are available.

Editing designs function: Edit the wrong design or modify the old design directly through the computer. No need punching it again. Editing design such as pattern rotating, pantograph, condensation, duplication, performance of repetition, cycling sewing and bulk sewing are available. And modify, insert or delete your design data stitch by stitch.

Safety Guard: Computer, servo-motor or machine has any abnormity, the computer will automatically show all faulty details in the LCD.

ERROR DETECTION DISPLAY: Error massages are displayed on the monitor until the condition is corrected

14"Color LCD display: working process, designs, and needle space and coordinate etc. all will show on the LCD.

Built-in floppy disk drive: The built-in 3.5 floppy disk drive, 150 patterns memory. Stitch conditions can be saved in a floppy disk together with quilting data. The saved stitch conditions are applicable to reproduction or subsequent machines.

Technical Specifications

Control Type:NC simultaneous 2-axis control, linear/arc interpolation

Motor: Saddles and rollers driven by Panasonic servo motor ;

Stitch Type: Shuttle

Shuttle:7# 10#

Max. Quilt Thickness (non-compressed foam + polyester wadding): 40mm

Needle number:*16-*21

Working Speed:400-600R/M

Power Supply:380V or 220V according to customer requirement.

Power Consumption: 5.4kw