| Model: | API 5L,AS 1163 |

|---|---|

| Brand: | API 5L,AS1163,ISO 3183, EN 10219 HFW Pipe |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | API 5L X56 ERW Pipe , ASTM A53 WELDED PIPE , EN 10208 STEEL PIPE |

| Price: |

US $1215

/ MT

|

| Min. Order: | 20 MT |

| Live Chat: | Last Online:11 Dec, 2022 |

|

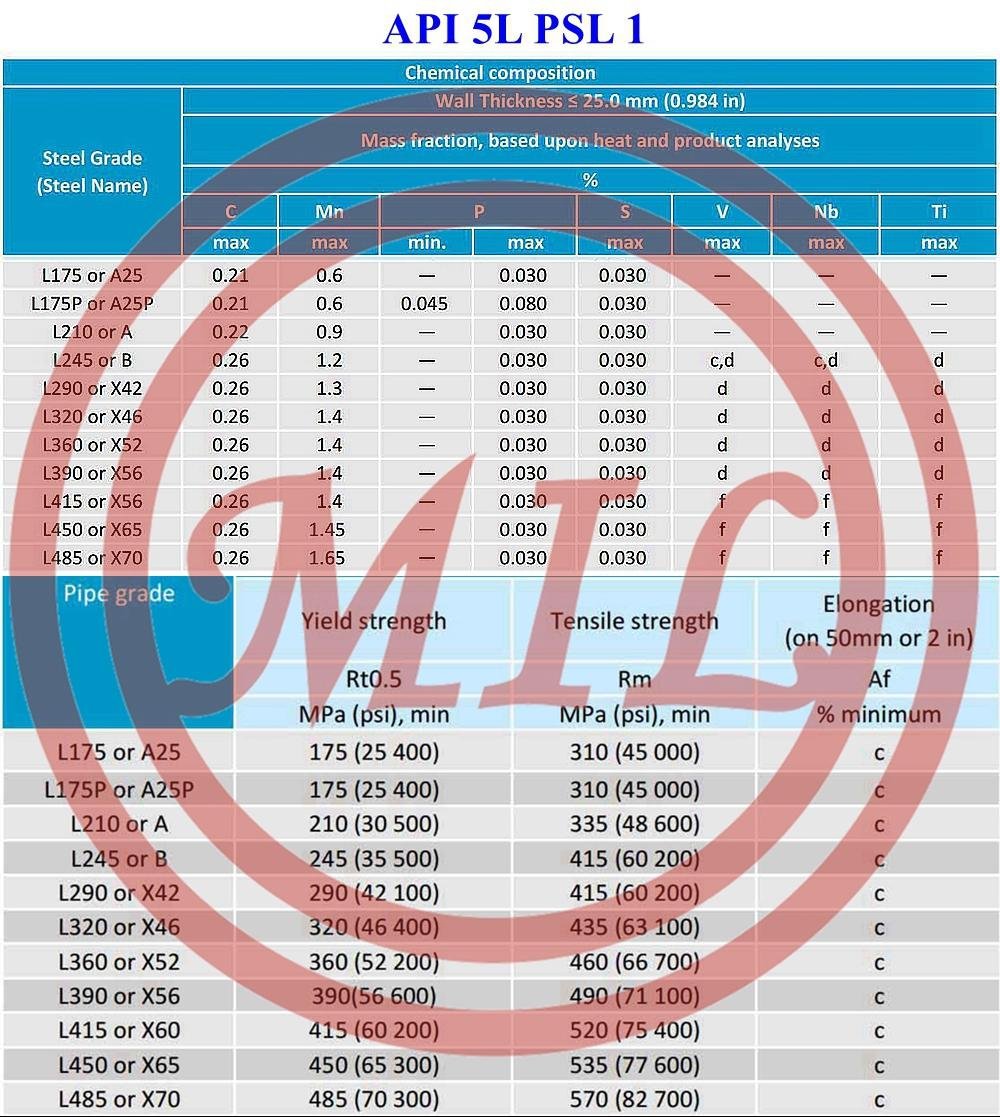

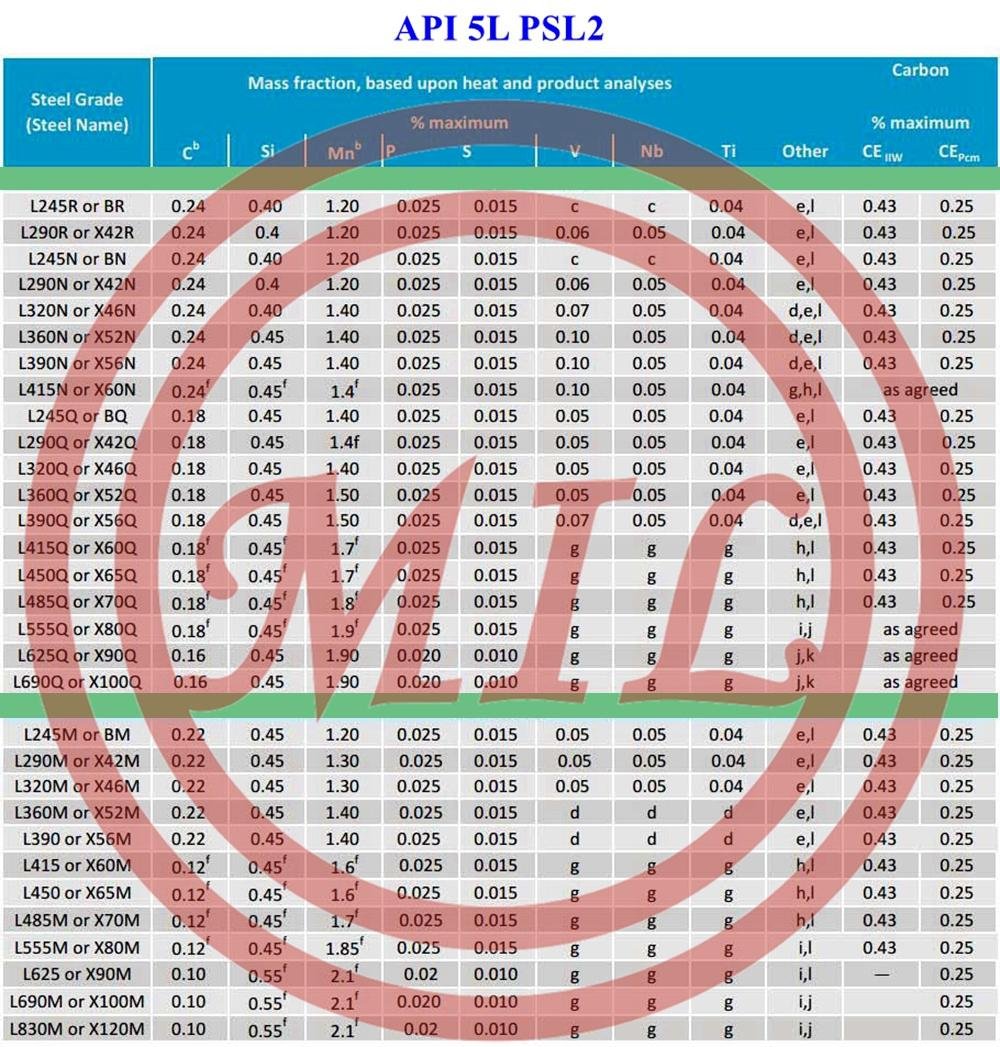

Reference Standards:

API 5L PSL 1,2 & 3,ISO 3183-1,2 & 3, AS 1163,AS 2885.1,CSA Z245.1, DIN 17172, EN 10208-1,2 & 3, DNV OS-F101,EN10217-5

NACE MR 0175/ISO 15156-2,NACE TM 0177,NACE TM 0284

BS 3602-2, BS 6323-7,GOST 10704,IPS-M-PI-190, IGS-MS-PL-001,GOST 20295,GOST R52079,KOC-MP-019,KOC-MS-001,NFA 49-211,NFA 49-411, NRF-001-Pemex-2007

DEP 31.40.20.30 (Non-Sour),DEP 31.40.20.31 (Sour),DEP 31.40.20.35,DEP 31.40.20.37, DGS-9510-001, 01-SAMSS-035 and 01-SAMSS-038,TOTAL GS EP PLR 202,TOTAL-GS-PLR-212

ASTM A252, EN 10219-1/2, AWWA C200, BS 3601-1, DIN 2460

API 2B, API 2H, API 2W

DIN 2470-1 & 2, DIN 17120, DIN 17174,

EN 10217-1/3 EN 10220, EN 10224,EN 10255, EN 10296-1

JIS G 3444, JIS G 3457, JIS 5525,KS D3566, AS 1579

ASTM A134,ASTM A139,ASTM A155, ASTM A671,ASTM A672,ASTM A691,ASME B31.1,ASME B31.3

CSA Z.245.21, DIN 30670,ISO 21809-1, NFA 49-710, AWWA C215

DIN 30678, NFA 49-711

AWWA C222, EN 10290

CSA Z 245.20,API RP 5L7, ISO 12944,ISO 21809-2,AWWA C213, AS 3862,NACE SP394

API RP5L 2, AWWA C210,EN10289, EN 10290, EN 10301,ISO 15741,NFA 49-709

ISO 21809-5, DNV-OS-F101

AWWA C203,

AWWA C205, DIN 2614, BS 534