| Model: | - |

|---|---|

| Brand: | Spark |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | - |

| Price: |

US $25

/ pc

|

| Min. Order: | 10 pc |

| Live Chat: | Last Online:28 Sep, 2022 |

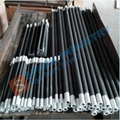

Molybdenum Disilicide Heating Element, Ceramic Refractory Smelting Furnace Heating Element

MoSi2 Heating element is a High-Density Material consisting of Molybdenum Disilicide and self-forming glaze of silicide dioxide. It can be used up to Furnace Temperature of 1800℃. These elements have a long service life.

MoSi2 Heating element is a special material that has the best properties of both ceramic and metallic materials. It withstands corrosion and oxidation, like ceramic materials and has a low thermal expansion. And it also has good thermal and electrical conductivity, like metallic materials. Thermal shock does not have any effect on the element and as a heating element, it can withstand many years of service because of its strength.

Molybdenum Disilicide Heating Element Feature

Application:

| Item | name | distinction criterion | specification |

|

Heating elements |

1700 type | Element operating temperature 1700℃ is acceptable | Le Φ

6-12W type/U type/L type/all kinds of heating element |

| 1800 type | Element operating temperature 1800℃ is acceptable | ||

| 1800J type | Element operating temperature≥1800℃ | Le Φ

3-12W type |

|

| 1800T type | Element operating temperature≤1800℃ | Le Φ

3-12W type U type |

| Small furnace (power100KW) | Large furnace(Power 100-500KW) | ||

| Furnace temperature | Voltage | furnace temperature℃ | Voltage |

| 20-150 | 1/3 Operating voltage | 1/3 Operating voltage200-300 | 1/3 Operating voltage |

| 150-500 | 2/3 Operating voltage | 300-700 | 2/3 Operating voltage |

| 500-operating temperature | The Whole-Operating Voltage | 700-Operating temperature | The Whole-Operating Voltage |

Recommend surface load:

| Furnace Temp(°c) | 1400 | 1500 | 1600 | 1650 | 1700 |

| Surface load of hot zone(W/cm²) | <18 | <15 | <12 | <10 |

<8

|

| Payment Terms: | TT / LC / PayPal |

|---|---|