| Model: | wds-650 |

|---|---|

| Brand: | WISDOMSHOW |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | Motherboard Repair M , xiaomi chip repair , computer motherboard |

| Price: |

US $4800

/ set

|

| Min. Order: | 1 set |

| Live Chat: | Last Online:01 Nov, 2019 |

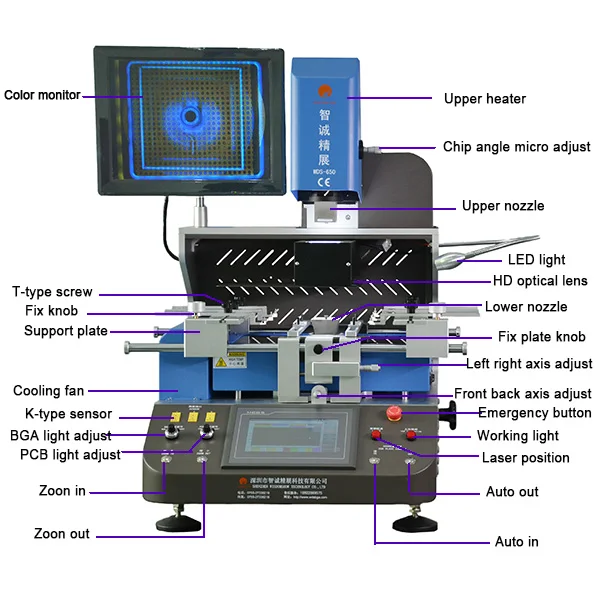

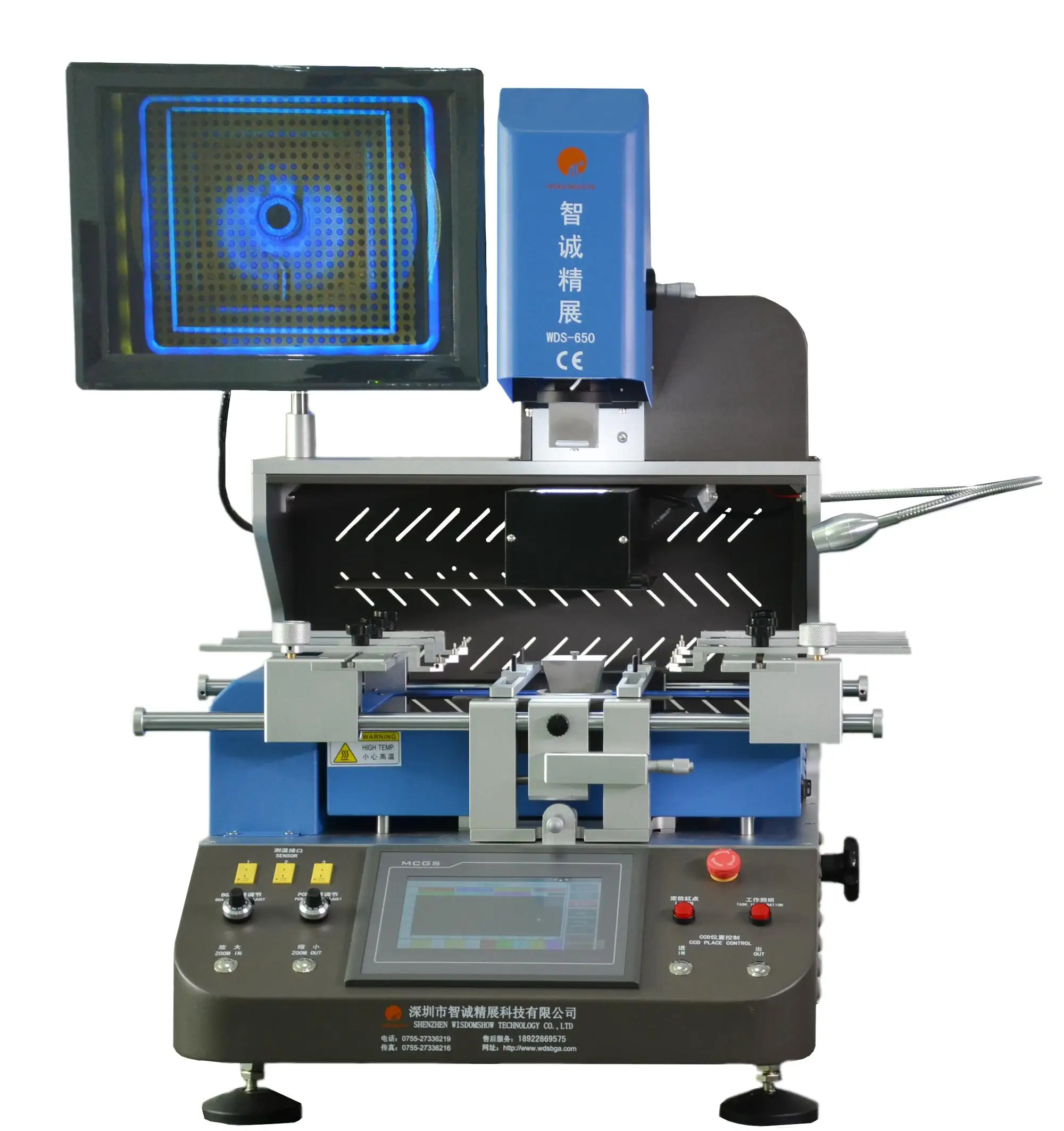

Automatic Motherboard Repair Machine WDS - 650 For Iphone 6s Motherboard Repair

Product Description

Specifications

|

Power supply |

AC 110V/220V±10% 50/60Hz |

| Total power | Max 6800W |

| Heater power | Upper temp.zone 1200W,second temp.zone 1200W,IR temp.zone 4000W |

|

Locating way |

V shape slot,PCB support jigs can adjust,laser light do fast centering and position |

|

Temperature controlling |

(high precision K-sensor)(Closed Loop),independent temp.controller,the precision can reach ±1℃ |

|

Electrical material |

Driving motor+ smart temp.controller+color touch screen |

|

PCB size |

Max 410×380mm Min 10×10 mm |

|

Applicable chips |

Max 70×70mm Min 1×1 mm |

|

Applicable pcb thickness |

0.3-5mm |

|

Alignment system |

Optical lens + HD industrial camera |

|

Mounting accuracy |

±0.01mm |

|

Temperature Interface |

3 pcs |

|

Tin spot monitoring |

Optional external camera to monitor solder ball melting process during welding |

|

Camera in and ou |

Auto out & in |

|

Overall dimension |

L600×W640×H850mm |

|

Weight of machine |

60KG |

|

Other function |

5 working modes. Auto/ manual mode switch freely |

Functional Characteristics

Independent 3 heating zones temperature control system

1.The upper and lower hot air heating, IR preheating zone adopts imported infrared gold-plated light tube to heat up quickly,which can heat up at the same time from the top of he component to the bottom of the PCB, to make the PCB board heated averagely,ensure welding effect;bottom IR heating,temperature precision control within ±1℃.8 segment temperature control independently.Infrared gold-plated light tube control heating independently.

2.Hot air district heating for BGA and PCB at the same time,and large area IR heater preheating up for the bottom of PCB to avoid completely PCB deformation during reworking,the upper or lower temperature zones could be used alone and combine freely the energy of up and lower heating element.

3.Adopted high precision K-type thermocouple close-loop control and PID parameter self-setting system;

4 temperature curves can be displayed with instant curve analysis function and multi-group user data can be saved;temperature can be tested precisely through external measurement interface,curves can be analysed,set and correct on the touch screen at any time.

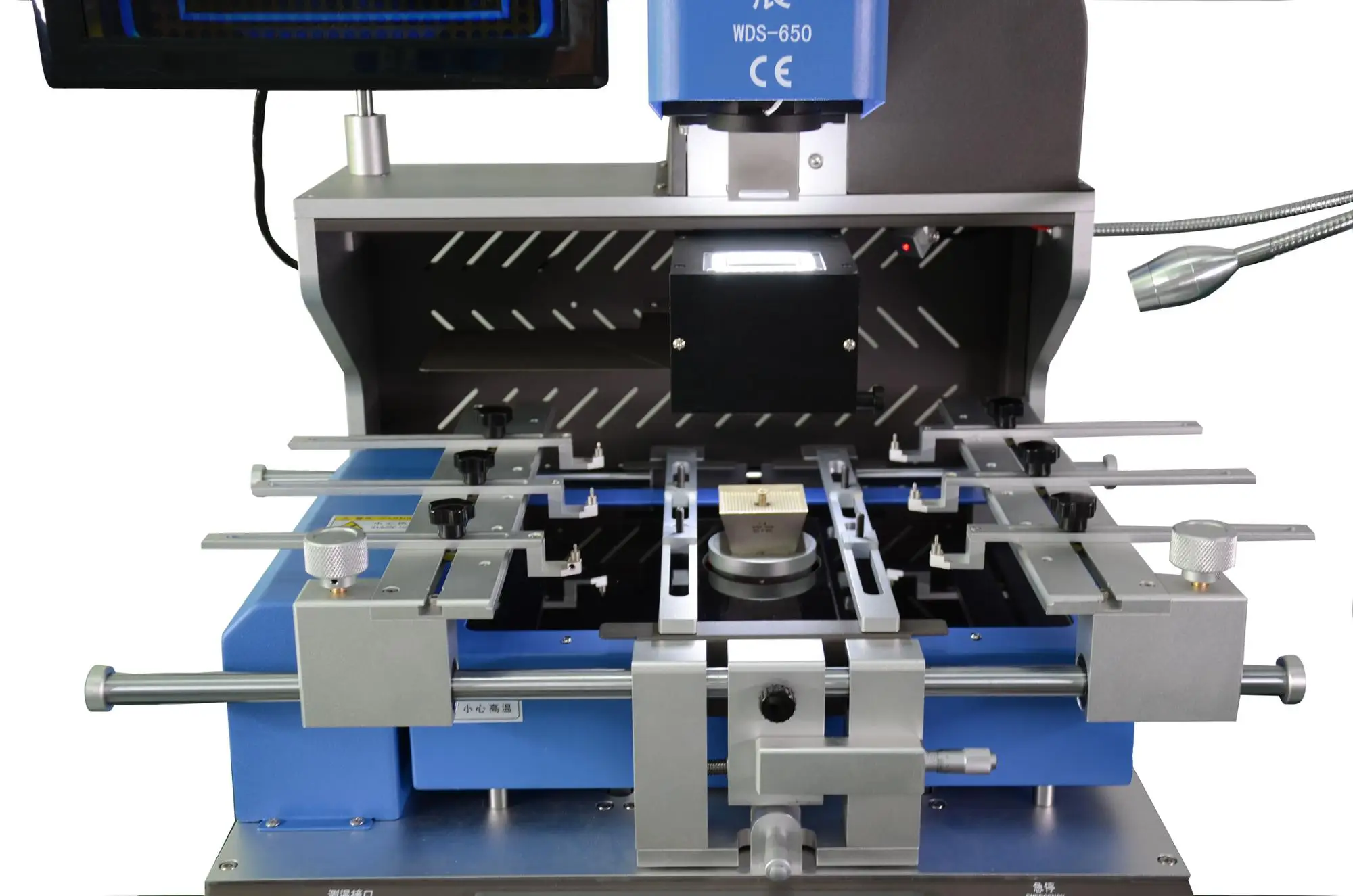

Precision optical alignment system

Using high definition and adjustable CCD color optical alignment system,beam split,amplification,lessening,fine adjustment and auto focus with the function that automatic color aberration resolution and brightness adjustment,adjustable image contrast;equipped with 15 ” high definition LCD monitor.

Multi-functional and humanized operation system

1.Adopting the HD touch human-machine interface;upper heating head and mounting head designed 2 in 1;providing many kinds of titanium alloy BGA tuyere can be rotated in 360 degree for easy installation and replacement.

2.X,Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach ±0.01mm.

Superior safety protection function

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of temperature abuse, the circuit can power off automatically with the double over-temperature protection.Temperature parameter having password protection to prevent any modification.

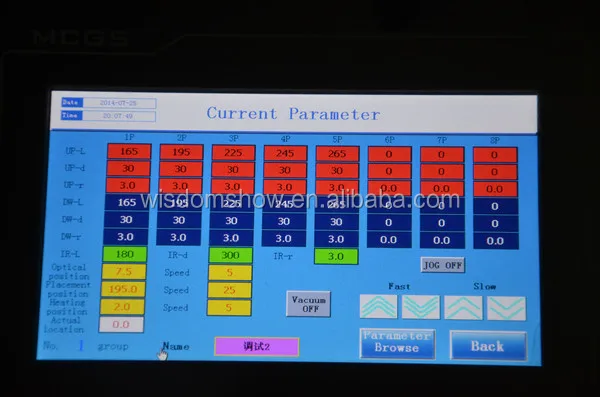

Screen Display

1.Up Temp: Indication current upper heater temperature with red line

2.Down Temp: Indication current down heater temperature with green line.

3.IR Temp: Indication current IR temperature with blue line.

4.Sensor : Indication set temperature change of external sensor in water blue line

5.Current place: Indication the height of Upper heater away from the lower heater.

6.Start Temp: Indication the starting temperature for checking the time of Warm-up section.

7.Done Temp: Indication the ending temperature for checking the time of warm-up section.

8.Parse Time: Indication the system analysis time for 1 to 8 each stage

9.Curve Select: Operating the previously saved program

10.Current Curve: Name of the adapted program

11.Remove/Mount/Weld/Manual/Semi-automatic : Clicking it the select the operation type of the machine.

12.Run: Clicking it to start working as the parameter setting.

13.Stop: Clicking it to stop working .

14.Alignment OK:Under “mount”mode,click it,the upper heater goes down to heat automatically.

15.Manual Operate: Setting the upper heater operation by self .

16: BACK: Return to the previous interface.

Our Services

1.Your inquiry will be replied in 12 hours.

2.Original Manufacture to customers, with competitive price.

3.We provide one year warranty, free training.

4.Well-trained and Professional after-sales service team to support you.

5.Manual and Demo video CD will package with machine, It will show you how to use machine step by step.

6.Payment terms ,like T/T, Westerunion, PayPal is choosed by customers.

Packaging & Shipping

1,Standard export wooden package for bga rework station;

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL,FEDEX (IE), Aramex or by air or by sea

4,Loading Port: Shenzhen or Hongkong

Company Information

Certifications

1.We are the Manufactuer = own factory+ machine design+Sheet metal produced by ourself +spray the powder+ strong assemble the machine team + packaging+free training;

2.Logo/Brand:Customer's designs and logos are welcome,we can silk-print your own logo company;

3.HUAWEI,TCL,ZTE,MEIZU,KONKA,LENOVO,FOXCONN vendor;

4.Have good market in Korea,Japan,NorthAfrica,Vietnam,Brazil,Turkey,India,Mexico and South Asia,The Mid-East and European countries;

5.100% NEW from WDS factory;

6.Over 20 R&D engineers, with 10 year experience;

7.Over 100000 Global User;

8.All models approved CE ISO9001;

9.100% QC inspect before shipment;

10.High quality & competitive price.

| Payment Terms: | TT/Westerunion |

|---|---|