| Model: | MIM-0003 |

|---|---|

| Brand: | BRM |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metal Mineral |

| Label: | phone accessories mo , mobile phone accesso , shenzhen mobile phon |

| Price: |

US $0.6

/ pc

|

| Min. Order: | 100 pc |

| Live Chat: | Last Online:17 Aug, 2017 |

Product Description

|

Brand Name |

BRM |

|

Forming Method |

MIM(Metal Injection Molding) |

|

Material |

SS316L |

|

Application |

Telecom,Military,Surgery,Watch,Machine Tool... |

|

Post Treatment |

Machining, Heat treatment, sizing etc. |

|

Surface Treatment |

Plating,Coating,Spray Coating,etc... |

|

Tolerance |

General:±0.5% of dimension |

|

OEM |

Available |

|

MOQ |

It depends on your parts’ size or shape |

|

Quality Control |

100% inspection on critical dimensions before shipment. |

|

Drawing Format |

2D: PDF/ DWG/JPG/DXF 3D: IGS/ STEP/PRT |

|

Payment Terms |

T/T, Paypal, West Union, L/C, DDP, DDU, Credit Card etc. |

|

Delivery Time |

Tooling:15-21 working days Sample:5-10 working days |

MIM Technology

Meta Injection Molding (MIM) is a high-tech near net shape technoloy to mass production of small metal parts with complex shape, high precision and performance requirement. MIM technology has ts advantages over traditional powder metallurgy, machining, investment casting, and other alternative methods. MIM parts can now be found in all areas of life, from our cars and trucks to watches, dental braces, mobile phones, IT equipment, DIY tools and much more.

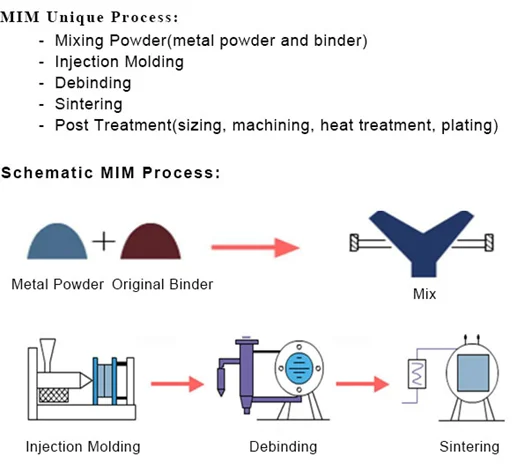

MIM Process

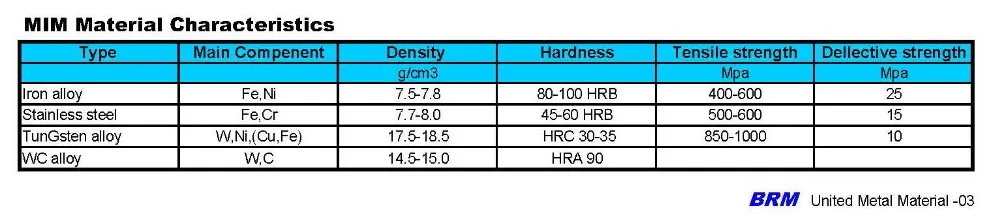

MIM Characteristics

Our Factory

|

Company Name |

Shanghai United Metal Materials Co., Ltd |

|

Year Established: |

2006 |

|

Main Product |

Metal injection molding, Rare earth magnet, Bonded Neodymium magnet, Sintered Ndfeb magnets, Smco magnet, Hard ferrite ceramic, soft ferrites, rubber magnets, Die casting. |

|

Certifications |

ISO9001, TS16949, ISO14001, GB/T28001 |

|

Services |

1) Our engineers provide you the better solution for your design. We involve our customers in the development process of their products right from the beginning. 2) We provide effective and prompt customer service, our innovative solutions result in competitive advantages for our customers. 3) Keep the competitive cost. |

FAQ

1, What format of drawings are we using currently?

We need the 2D and 3D drawings commonly, the software that we use are AutoCAD, solid-works, UG, pro-E.

2D: DWG, PDF, JPG,

3D: STP, IGS,

2,How to get the exact quotation asap?

2.1 Firstly we need to have the 2D drawings and 3D drawings, in which there are material, detailed dimensions, geometric tolerances, and other necessary parameters; for magnets, the magnetic characteristics such as Br, HCJ, HCB, (BH) max are very necessary.

2.2 The monthly or annual requirement in quantity;

2.3 What is the part/component used for; it means usage.

2.4 surface treatment such as sand blasting, plating, coating…

3,What is the MOQ of order ?

3.1 Generally it depends on the shape and the tolerances of part/component,

3.2 MOQ is only for mass production period;

3.3 It is not for the period of development of project;

4, What’s surface treatment can be used for …

It can be checked on the description page, generally we choose the following treatment, but if customer need the special treatment, we can provide by our suppliers.

Plating,

E-coating, spray,

Electro-polish,

Sand blasting,

Magnetic polish,

Anodic oxidation etc.

5, Can the documents of PPAP (ISIR), FMEA, CP, GR&R, DFM be supplied.

Yes, we can provide this kinds of documents;

6, Lead time, how long is it commonly?

6.1 lead time for tooling/mold/jig: 2-3 weeks generally;

6.2 lead time for making samples: 1-2 weeks generally;

Contact Us