| Model: | - |

|---|---|

| Brand: | Xingnuo |

| Origin: | Made In China |

| Category: | Transportation / Transportation Facilities / Other Transportation Facilities |

| Label: | concrete sleeper |

| Price: |

US $100000

/ set

|

| Min. Order: | 1 set |

| Live Chat: | Last Online:15 Oct, 2015 |

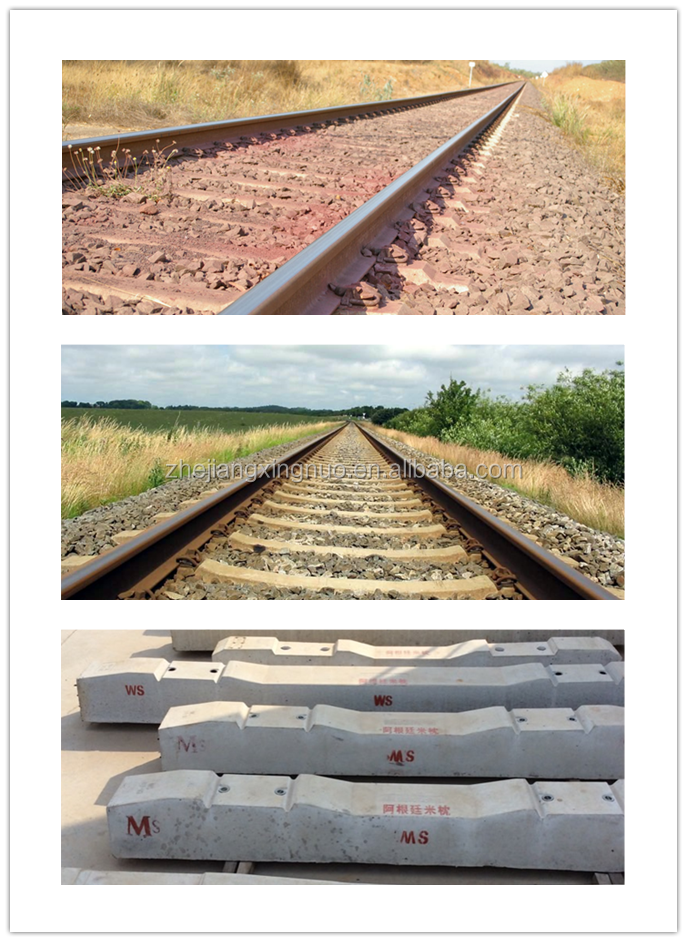

History of the Railway Sleeper:

In 1877, Joseph Monier, a French gardener, s ested that concrete reinforced with steel could be used for making sleepers for railway track. Monier designed a sleeper and obtained a patent for it, but it was not successful.

Concrete sleepers were first used on the Alford and Sutton Tramway in 1884. Their first use on a main line railway was by the Reading Company in America in 1896.

Designs were further developed and the railways of Austria and Italy used the first concrete sleepers around the turn of the 20th century. This was closely followed by other European railways.

Major progress was not achieved until World War II, when the timbers used for sleepers were scarce due to competition from other uses, such as mines.[1] Following research carried out on French and other European railways, the modern pre-stressed concrete sleeper was developed.

Interest in concrete railway sleepers increased after World War II following advances in the design, quality and production of pre-stressed concrete.

Until now, a huge improvement on concrete sleeper.

Railway Sleeper Includes:

Common sleeper: Used in single-chord , station lines laid

Switch sleeper:Used in build switch area

Bridge sleeper:Used in bridge deck line laying

At present, Chinese standard railway gauge is 1435 mm

|

Concrete sleeper type |

Width(mm) |

Thickness (mm) |

Length(mm) |

Note |

|

Common sleeper |

220 |

160 |

2500 |

|

|

Switch sleeper( common) |

220 |

160 |

2600~4850 |

Carry 150 mm . Total about 16 specs for length |

|

Switch Sleeper (standard) |

240 |

160 |

2600~4800 |

Carry 200 mm . Total about 12 specs for length |

|

Bridge sleeper |

220 |

240,260,280,300 |

3000 |

|

The Definition of Rail Sleeper Mould:

Rail sleeper mould is the foundational machine of the railway track laying. And it’s also an important and indispensable machine for the upper rail construction. It’s used to prefabricate cement and concrete cover plate fabrication in building railways.

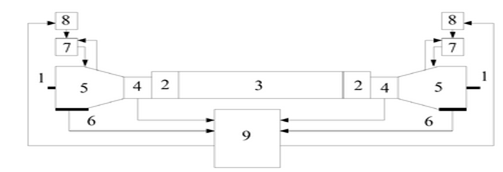

Automatic Railway SleeperTensioning Machine:

Automatic concrete sleeper tensioning machine (ATM-300) is dedicated equipment designed for sleeper production line. It is mainly composed of tensioning jack, sensors, human-computer interface, PLC, console, tensioning car and oil pump station. The system has high reliability, high control precision and the large capacity of data storage, query convenient, work fast, simple operation, easy maintenance, etc advantages.

Note:

1. Prestressed bar 2. Anchorage 3.Prestressed element 4.Pressure sensor 5.Tensioning jack 6.Displacement sensor 7. Two-position three way electromagnetic ball value 8.oil pump 9. Controller

Concrete Railway Sleeper Feeding Machine:

The concrete railway sleeper feeding machine composed of frame, hanger plate subassembly, hopper, hopper door opening mechanism and walk mechanism etc.

parameters

1.Railway gauge: 1750mm

2.Capacity: 3m3

Railway Sleeper Vibration Table:

1. The first stage is the mould need to vibrate in the vibration table about 2-2.5min called common vibration. The main function is to make the Concrete vibration close-grained and bleeding. Meanwhile to flat ash. Let the concrete quantity same in the 10 sleeper model.

2. The second stage is the mould continue to vibrate in the vibration table. Meanwhile put the Embossing cover plate on the top of the mould and hold the sleeper subface concrete.

Technical parameters:

1.Frequency: 1500times/min

2.Amplitude:0.5mm

3.Total Vibration Force(Adjustable) : 667Kg

4.Motor Power : 37-45KW

Roll over machine for railway concrete sleeper:

The railway concrete sleeper mould rolling over by special equipment. The concrete sleeper appears displacement between models because being released,Cut the adhesive force between concrete sleeper and mould, when the model on the machine turn 180 °the wire connected to the two rows of 5 root sleeper can demouldsmoothly and into the finished productroller way to continue to the next working procedure. Roller over machine also make railway concrete sleeper by backwards into a positive direction.

Specifications:

1.Speed of corbel: priority selection 2R/min.

2.Motor power: >22KW.

3. Motor type: double ended machine.

4.Fasteningtype :hydraulic lock.

5. Flip type: Mechanical turnover.

Professionstacker crane machine for concrete sleeper:

When the concrete sleeper product from the end of the workshop into the open-air finished-parts storage. There are two types of stacker crane: One increase swing and retractable guide frame rigidity on the basis of lifting car,other one rigid guide frame fixed on the lifting the car. Sleeper move transversely device and crane served concrete rail bearing transport from one side of the workshop to outdoor finished-parts storage. Cut the steel wire between concrete rail bearing sleeper in finished product transportation roll. Move the concrete rail bearing to cross rail outside then transport tostocking yard by crane and car.

Specification:

1. Lifting speed: 6-8m/min

2. Walk line speed: 30-36m/min

3. Capacity:≥1250Kg

4. Maximum lifting height:≤2700-3000mm

Roller Way For Concrete Sleeper:

As a important and effective production machine for concrete sleeper , concrete sleeper roller way is used for transport concrete sleeper mold to different directions during production process . Concrete sleeper production adopt Assembly line process,mold Use cranecome in and go outsteam pool,others are transmitted by roller. The application of roller effectively reduced the output of labor,enhance the automation of the whole process. Production more efficient and accurate.

Railway Concrete Sleeper Curing Temperature Control System:

Railway sleeper curing is a very important part during concrete sleeper production process.The curing affects products quality . The compactness and permeabilityof concrete also influenced.

Technical Requirement

1.Time not too long, external cement particles produced film affect internal particles because of hydration. Temperature below 70 ℃, Otherwise you will make the internal structure damage again.

2.Delaying curing time not less than 2 hours,heating rate should not be greater than 15 ℃ / h, Pool temperature less than 60℃, Cooling rate should not be greater than 15 ℃ / h, temperature differential method Less than 15℃.

Main Technical Specifications

1. Temperature control error : ±1℃;

2. control method:Control method Combination of manual and automatic control;

3. Adjust Method:Solenoid valve;

4. Data administration: long-stem storage,query at any time,at any time to print,data presentation by usinggraph.

5. Process curve of choreography:The user personal customized according to need.

6. Setting of process parameters:Parameterthrough the panel remote Settings and protected by password.

Packaging:

Different Machines with Different Package, The products should be processed to be rustproof and moisture proof before delivery. The barrels are nude packed, Motors, Electric Switch Box and spare parts are packed in wooden cases.

Our services:

1.Complete production line supporting machines and all necessary accessories with high performance and good quality;

2. Free Service of plant structure design and layout plan drawings and other necessary construction drawings and guidance of construction work,office, warehouse etc and related drawings according to customers’ requirements.

3.Installation and commissioning of all production machines as well as the workers training.

Our customers:

We will make every effort to provide different satisfactory solutions for prestressed concrete pole project according to different requirements of our clients all over the world!

We promise our customers:

High Qaulity ,

Professional Guidance,

Satisfactory After-Sale Service!

Warmly Welcome To Visit Our Factory !