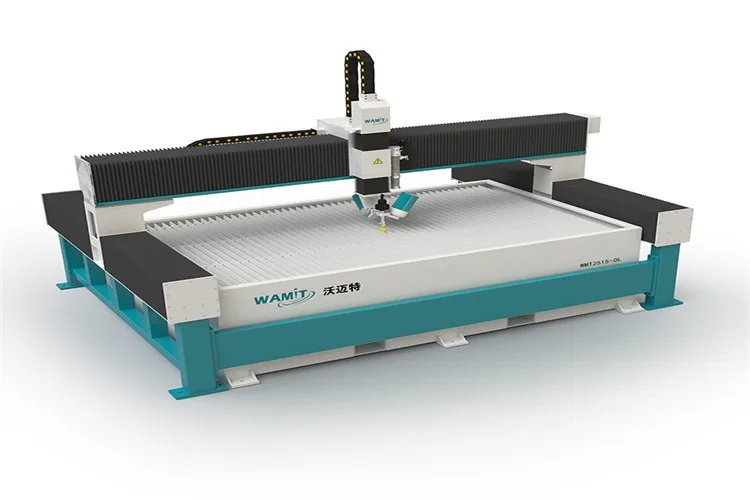

| Model: | WMT2015-AL |

|---|---|

| Brand: | WAMIT |

| Origin: | Made In China |

| Category: | Industrial Supplies / Glass & Ceramics Machine |

| Label: | marble cut machine , cutting machine , CNC cutter |

| Price: |

US $32900

/ pc

|

| Min. Order: | 1 pc |

| Live Chat: | Last Online:22 May, 2020 |

China top quality Marble Mosaic waterjet cutting machine

A full set of abrasive waterjet cutting machine includes work table, pump,CNC controller, High pressure system with cooling system, Auto abrasive feeder, Water treatment and Abrasive removal system,etc.

Equipment framework adopts supper heavy support system. The heavy-duty support of the equipment is rigid enough to ensure the stability under long-span and high-speed operation. With a multi-point fixing method in the length direction of the frame, there is no any deformation displacement during operation, which ensure the cutting accuracy.

Main Features

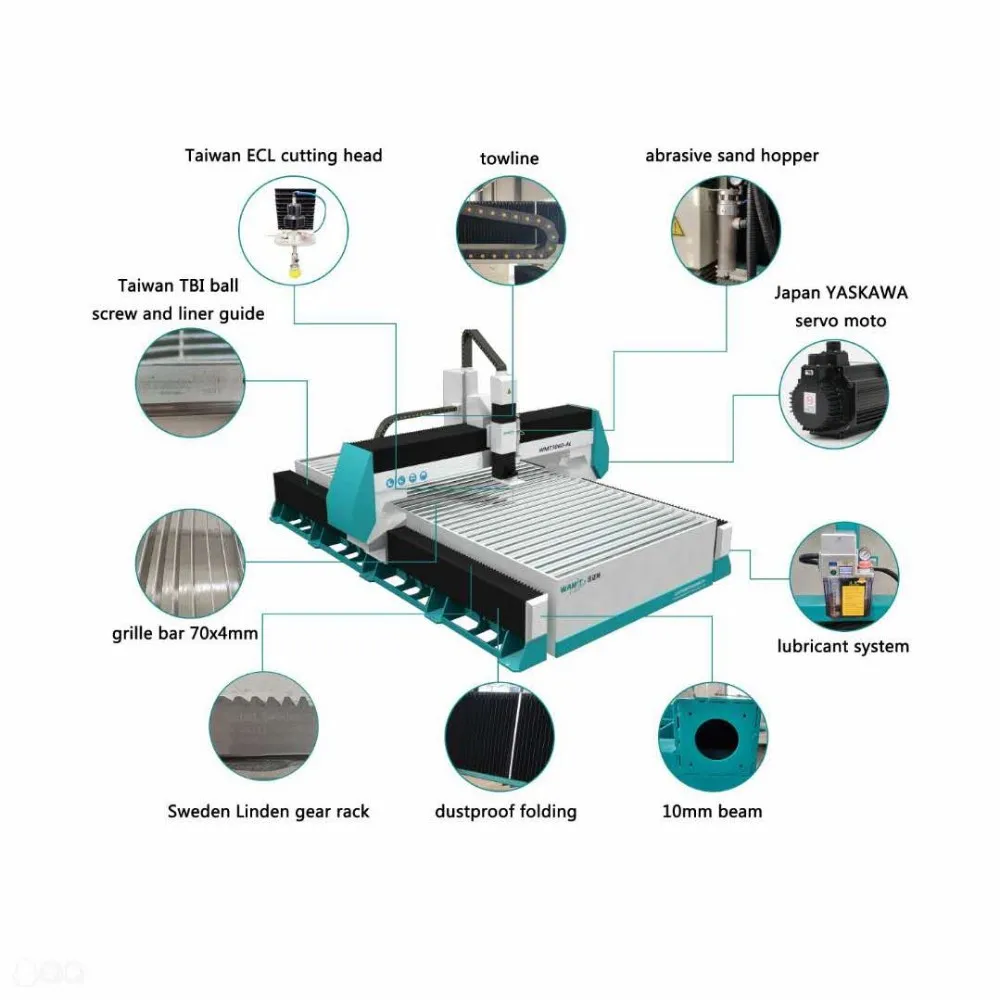

1. Gantry type balanced design work table, solid and stable, higher strength

2. Work table of CNC motion mechanism and workpiece supporting adopts a split structure, which eliminates the influence of water gushing on cutting precision during cutting

3. X-axis,Y- axis use high quality LINDEN SWEDEN rack and pinion, HIWIN rail, which ensure the accuracy of bearing parts, stable conveying, hard-wearing quality. During cutting, it causes splashing sand and water. Fully enclosed lifting structure design in Z-axis prevents corrosion of lead screws and guides.

4. Integrated automatic lubrication system make the maintenance more automatic and easier.

5. All electric components are Schneider brand

6. Equipped with YASKAWA AC servo drive power and motor ( Japan brand), high accuracy, long service life.

Size

Can be customized to any size, mini platform or ultra-large platform or other size can be customized.

|

SPECIFICATIONS FOR WATER JET CUTTING MACHINE |

||||||

|

Model |

WMT 1010 |

WMT 2050 |

WMT 3020 |

WMT 3080 |

WMT 5030 |

|

|

Cutting table |

X axis(mm) |

1200 |

2200 |

3200 |

3200 |

5200 |

|

Y axis(mm) |

1200 |

5200 |

2200 |

8200 |

3200 |

|

|

Max.cutting range(mm) |

X axis(mm) |

1000 |

2000 |

3000 |

3000 |

5000 |

|

Y axis(mm) |

1000 |

5000 |

2000 |

8000 |

3000 |

|

|

Z axis(mm) |

250 |

250 |

250 |

250 |

250 |

|

Intenisfier pump

Maintenance free accumulator is imported from TAIWAN.

Intensifier assembly are imported from USA.

With SIEMENS motor and SIEMENS PLC and the motor is variable pump so that can reduce using cost.

All electric components are Schneider brand.

|

SPECIFICATIONS FOR HYRAULIC INTENISFIER PUMP |

|||

|

Max. Oil Flow Rate |

90 L/min |

||

|

Max. Water Flow Rate |

3.7L/min |

||

|

Max. Diameter Of Orifice |

0.33mm |

||

|

Max. Operating Pressure |

420MPa(60000 psi) |

||

|

Continuous Operating Pressure |

350-380MPa |

||

|

Power |

37KW(50HP) |

||

|

Type of shift |

Electronic |

||

Accessory equipment

CNC control system

CNC control, apply 21 inch LCD

Adopt specialized NCStudio water jet cutting software, have autosave function for next operation.

Apply SIEMENS PLC instead of relay, buttons are Schneider

Abrasive feeding system

No need electronic control, simple operation, reliable, maintenance-free

Can supply the cutting sand quantity

Need less than 0.2Mpa compressed gas pressure

Desanding system

Optional equipment.The desanding system provides a solution for the problem of removing waste sand of water jet cutters for users all over the world.

Production Process

Heat treatment

620 degrees in the furnace for 5 hours, down to 300 degrees for 3 hours, then naturally cooled in the furnace.eliminate internal stress in the welded frame.no deformation occurs during frame use,guarantee better cutting precision.

Shot blasting and powder coating

Remove impurities such as surface oxide scale to improve appearance quality.it can improve the fatigue fracture resistance of materials, prevent fatigue failure, plastic deformation and brittle fracture, and improve fatigue life.

Test

Test the straightness and parallelism of linear guide rail with precision measuring instruments.

Guaranteed higher precision when the equipment is running after the linear guide rail is installed.

Calibration

Calibrating equipment precision with a laser interferometer.guaranteed more accurate cutting precision.

Our Customer

Packaging & Shipping

FAQ

1. Are you manufacturer or trading company?

We are manufacturer of water jet cutting machine in JINAN city, Shandong, China.

2. What kind of material does your water jet cutting machine can cut?

There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic, rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and cast alloy.

3. What's your CNC water jet cutting machine's max. cutting thickness?

Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we s est cut no more than 150mm for smooth cutting. Now our Z axis distance is 170mm, we can customize for customers. Regular thickness please refer to: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm.

4. How we supply after-service?

Some countries we have after-service department, we will provide local service, if have no local service, we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days. And we also can provide installation videos.

5. What's your delivery time?

Generally speaking is 30 days. if have stock, 7-15 days.