| Model: | HT016 |

|---|---|

| Brand: | OEM ODM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

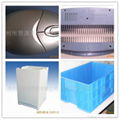

| Label: | plastic injection , custom plastic mold , plastic moulds |

| Price: |

US $0.1

/ pc

|

| Min. Order: | 10000 pc |

| Live Chat: | Last Online:24 Feb, 2016 |

Product Description

Advantages of ourplastic injection molding manufacturer:

We have a professional tooling design team with 13 years experience.

1)Various materials and short lead-time

2)Good steel and long lifetime .

3)We can supply "one-stop" service with molds opening, injection, painting, screen printing, assembly and nice after-sales service in long term

4)Full set of machines for mold making and injection molding

5): OEM&ODM service available

6): Mould's design based on tooling engineer from our company and experienced with years in the dustry.

7): Mould's steel as per customers' requests such as NAK80, S1369(H),2738, 718, 738 and etc.

8): Final products' materials' optional: ABS, PP, PE, POM, PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9): Products' color: As the customer's requirments, any color is possible, if they could provide us the color card schedule.

10): Relevant requirements reachable: RoHS, UL, or as the request.

11): Certifications Authorized: ISO9001&ISO14001 Certificated.

12): Japanese standard of QC management and Euramerican standard of checking.

13): Service scope: Open mould, Injection, CNC processing, coating, screen printing, assembly for finished products and so on.

14): Good cost and high effeciency of delivery.

Specifications of our plastic injection molding manufacturer :

|

Specification |

|

|

Certificates |

AAA grade credit enterprise, ISO9001, ISO14001, TS16949 |

|

Quality-guaranteed |

Japanese standard of QC management & Euramerican standards |

|

Service |

Mould design, CNC processing,tooling, assemble service, painting,etc |

|

OEM & ODM Service |

Acceptable |

|

Design Software |

UG, PRO-E, CAD, CAXA, etc |

|

Mould Base Standard |

LKM , HASCO , DME, etc |

|

Mould Material |

NAK80, S136(H), 2738, 718&738 and P20 etc |

|

Hardness of Steel |

15--60 HRC |

|

Cav/Core Material |

2738,2343,DIN-1,S130,2344,738H,718,8407,S136,NAK80,P20 etc |

|

Cavity |

Single/Multi |

|

Runner |

Hot & Cold Runner |

|

Mould Life |

300,000-1,000,000 shoots as required |

|

Final Product Material |

ABS, PP, PE, POM, PA6(66)+GF, PC, PMMA HIPS, GPPS etc |

|

Final Product Color |

Any color as required |

|

Lead Time |

25-50 workdays based on the different products |

|

Relevant Requirement |

ROHS, UL, or as requested |

|

Package |

Wooden case package or as customer requirement |

|

Price Term |

FOB Shanghai,Ex-works,CIF |

|

Payment Term |

T/T |

Cooperation Step

|

1.Research&Design |

We could provide R&D service. Design the files or improve the design based on customer’s requirement. |

|

|

|

|

2.Details Negotiation |

Finalize quotation , discuss quality, price, material, delivery time, payment issues ect. |

|

|

|

|

3.Placing Order |

Place order based on our final agreement. |

|

|

|

|

4.Mould Building |

According customers requirement to build the mould. Make final design confirmation before building mould.Send first sample to customer for final check before starting production. |

|

|

|

|

5.Sample Shoot |

If the first sample is not accepted by customers, we would modify the mould and resend the new sample to customer until see customer satisfaction. |

|

|

|

|

6.Product Inventory |

If order quantity is beyond inventory, we will produce and provide lead time as soon as possible. |

|

|

|

|

7.Delivery |

Deliver goods as customer required |

Certification

ISO9001:2000, ISO14001, TS16949

Packaging & Shipping

Packaging details: with standard export packaging or as customer's request

Shipping: air transportation, ocean shipping and sample for dhl, ups, tnt, etc

Our Services

Products service: Mould design, CNC processing,tooling, assemble service, painting,etc

Aftersale service: we provide aftersale service and techincal support.

Company Information

Suzhou Huitong Plastic Co., Ltd .

Huitong Plastic (Suzhou) Co., Ltd,which registered on Nov. 28th, 2002 in Suzhou, China , is a professional manufacturer of injection moulds and plastic products , mainly concentrating on design and manufacture of injection moulds for making plastic products, kinds of plastic components for home and office appliances, and relevant products with OEM service available all the times. To know more, pls see the website www.htsj.com.cn for your reference, thanks.

What you demand, we can do it for you!

We can supply "one-stop" service with molds opening, injection, painting, screen printing, assembly and nice after-sales service in long term, with good quality and competitive price .You can find our website : www.htsj.net.cn . Until now ,we built the good business relationship with Electrolux, Keytec, ERMAX,Makita,Philips. SAMSUNG, Checkpoint , MVS ,AURORA,RTC , , M.A.G .