| Model: | DH-A08 |

|---|---|

| Brand: | Dinghua |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | BGA Rework Station , BGA Soldering Machin , BGA Welding machine |

| Price: |

US $800

/ set

|

| Min. Order: | 1 set |

| Last Online:12 Sep, 2014 |

BGA Chip Reuse Machine BGA Reball Rework Station DH-A08

|

Total Power |

4800W |

|

Top heater |

800W |

|

Bottom heater |

Second heater 1200W, IR preheating 2800W |

|

power |

AC220V±10% 50Hz |

|

Dimensions |

L540×W560×H650 mm |

|

Positioning |

V-groove, PCB support can be adjusted in any direction with external universal fixture |

|

Temperature control |

K Sensor, Closed loop |

|

Temp accuracy |

±2℃ |

|

PCB size |

Max 360mmx350mm Min20mmx20mm |

|

BGA chip |

5*5~55*55 |

|

Minimum chip spacing |

0.15mm |

|

External Temperature Sensor |

1pc |

|

Net weight |

Approximately 28KG |

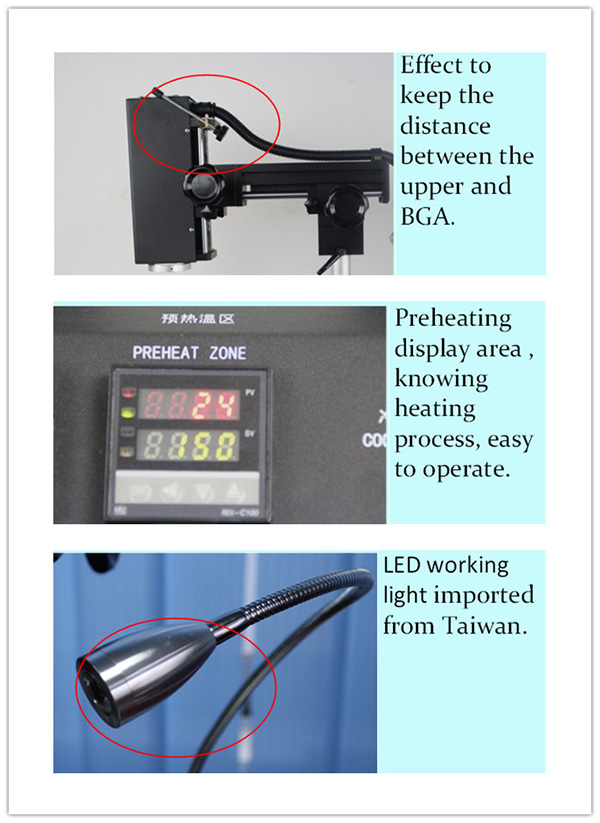

DH-A08 Feature

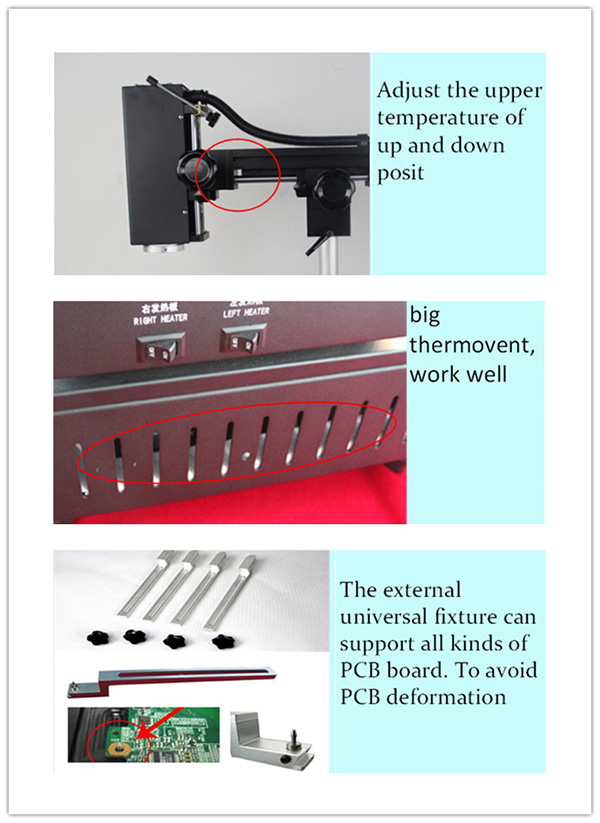

1.Designed in 3 temperature control. Upper and bottom are hot air heating, preheating area is IR heating.

All control temperature individually with high precision temperature control panel. And can set 8 temperature

up and down at the same time .Can save up to 10 sets of temperature settings simultaneously.

External temperature sensor enables timely control, adjust and managing every temperature data.

2.It uses precise K-type close circuit control and automatic temperature adjustment system, with

temperature module to enable precision temperature control of ±2 deg C. External temperature sensor

enables temperature monitoring and accurate analysis of real time temperature profile.

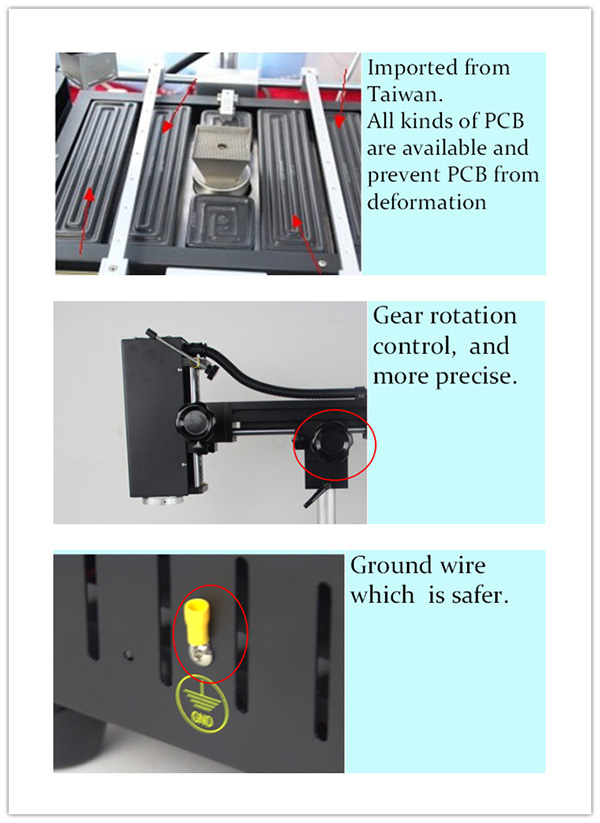

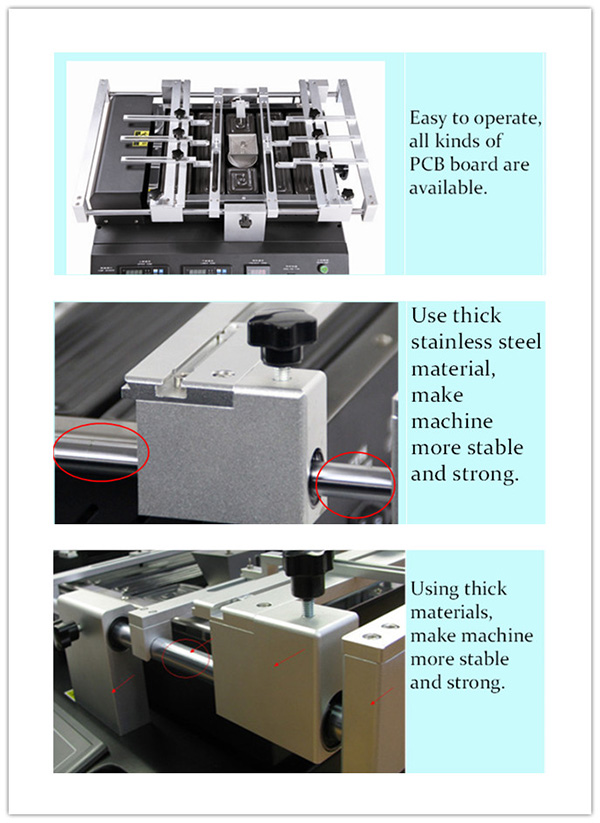

3.V-groove PCB support for rapid, convenience and accurate positioning that fits for all kinds of PCB board

4.Flexible and convenient removable fixture on the PCB board which protects and prevent damage to PCB.

It can also adapt to rework various BGA packages.

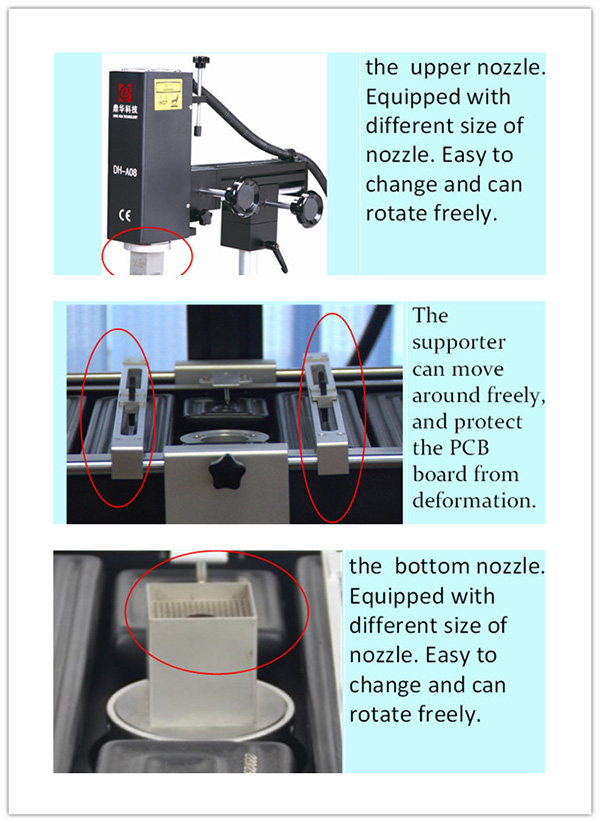

5.Various sizes of BGA nozzles, which can be adjusted 360 degree for easy installation and replacement;

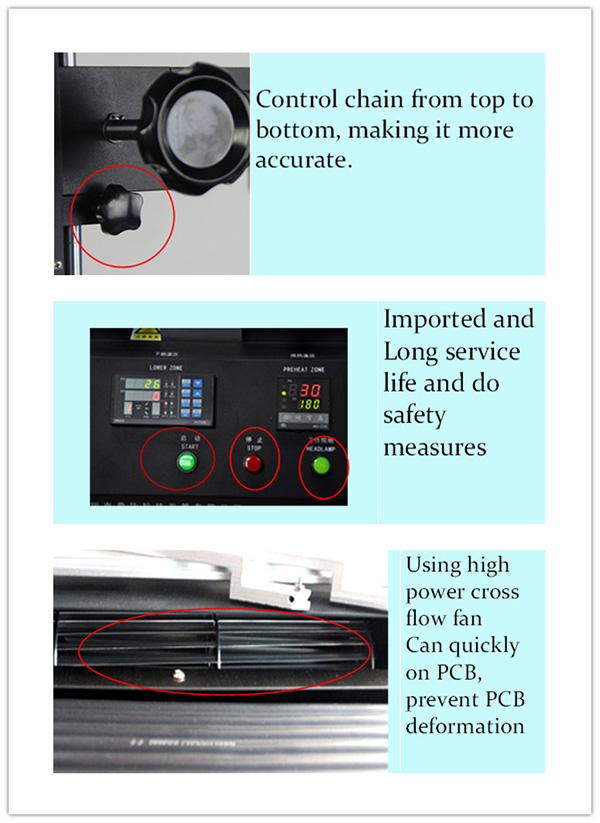

6.8 segment temperature up (down)+8 segment constant temperature control

7.Before the completion of uninstalling or welding, voice reminder / warning to get the workers prepared.

After uninstalling or welding After uninstalling or welding, high capacity horizontal airflow fan manually or

automatically cools down PCB to prevent PCB deformation and ensure quality of welding.

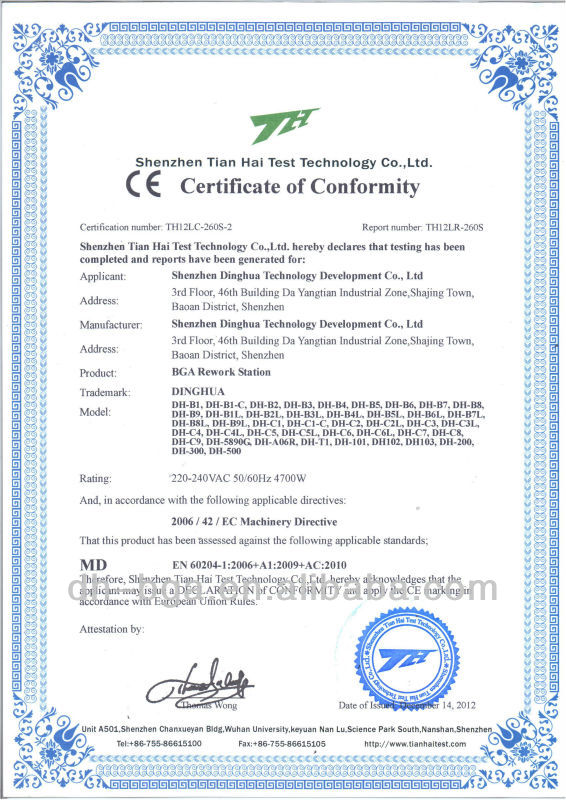

8.CE certification, with emergency switch and automatic power-off protection device when emergency happens

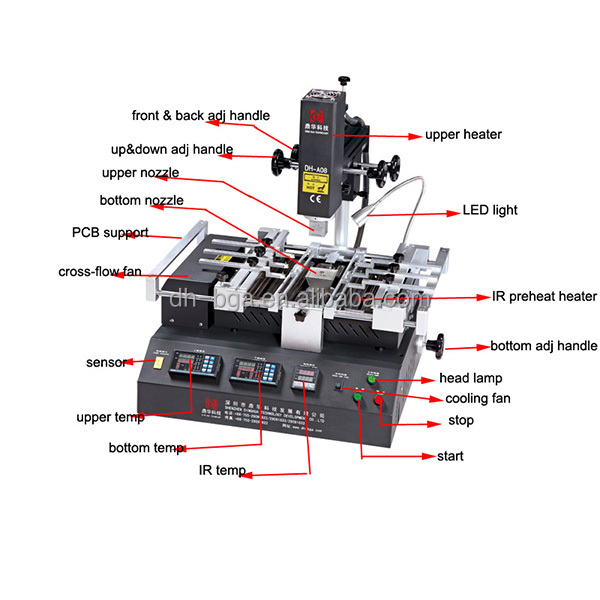

DH-A08 Structure

DH-A08 Function

|

No. |

name |

usage |

How to use |

|

1 |

limit knob |

Restrict the bit head down position |

Rotate to appropriate place |

|

2 |

Top heater |

The upper part of the hot air generated institutions |

|

|

3 |

Up and down handle |

Adjust up and down the location of the up head |

Rotate the handle |

|

4 |

LED |

Lighting when Equipment works |

Press the lighting button |

|

5 |

PCB clip |

Clamping the PCB, to the appropriate location |

Adjustment knob, move to the appropriate location |

|

6 |

Pre-heating heater controller |

Control preheat zone temperature |

start button , automatic heating

|

|

7 |

Lighting button |

Light switch |

Press the button |

|

8 |

Stop |

Stop heating |

Press the button |

|

9 |

Start |

Start heating |

Press the button |

|

10 |

Temperature sensor |

Connect an external galvanic measuring the actual temperature |

Directly connected temperature line |

|

11 |

Top heater nozzle |

Hot air more focused uniform |

Resorted to the appropriate location of the outlet from the BGA |

|

12 |

Bottom heating nozzle |

Hot air more focused uniform |

Resorted to the appropriate location of the outlet from the BGA |

|

13 |

Cross-flow fan |

Cooling PCB board after soldering |

|

|

14 |

PCB supporter |

Supporting the PCB without distorted |

Adjust the supporting columns |

|

15 |

Top heater controller |

Control of the upper hot air temperature |

start button , automatic heating |

|

16 |

Bottom heater controller |

Control of the lower part of the hot air temperature |

start button , automatic heating |

|

17 |

Fan switch |

Automatic and manual conversion of the cross-flow fan |

Switch to a different location |

DH-A08 Detail

Certifications

Warranty

1.All the machine will be well tested for 3 days before sending.

2.The whole machine is for 1-year warranty, the heating wire is for 3-years warranty

Packing & Shipping

1. The machine can be delivered by DHL, FedEx, TNT, EMS, UPS.

2. By sea or by air. Please provide us your nearest port.

3. The delivery date is within 7 days after the receipt of payment. If you are in urgent need of it,

please kindly tell us.

Company Information

Shenzhen Dinghua Technology & Development Co., Ltd is a professional manufacturer of BGA rework station,

rework tools and associated equipments, engaging in design, production, sales and service.We commit us to make

the professional equipment, provide the high quality a perfect service for the customer. As one of pioneer in this industry, we continue to improve and innovate along with the market demands by absorbing the advanced development

experience from home and abroad to adhering to our vision of ‘Professionalism, Honesty, Innovative and Responsibility’.

Science and technology are primary productive forces. Through teamwork, we achieved the core thermal-control

technology with related patent. At the same time, our products cover 3 categories: high-end, mid-end and low-end for

development and production using manual, semi-auto to fully automated processes. Our market had expanded into

industries like: individual repair, factories, education, military and aerospace etc. And we had established the point-of

sales and end service at locally and abroad.

Your satisfaction is our target, adhering to customer-focus, market oriented, and our company provides fist class

products and high efficient services for customers through continuous innovation. We are honored to work with you to

create a brighter future.

Our compay

Our customer

Our cooperation

Our Service

1. Your inquiry related to our products or prices will be replied within 24 hours.

2. Be Well-trained and experienced to answer all your enquires in fluent English

3. OEM&ODM, any your request we can help you to design and put into product.

4. Distributors are offered for your unique design and some our current models

5. Protection of your sales area, ideas of design and all your private information.

We always answer your questions: 24 hours a day, 7 days a week.

| Payment Terms: | TT/Western Union/cash |

|---|---|