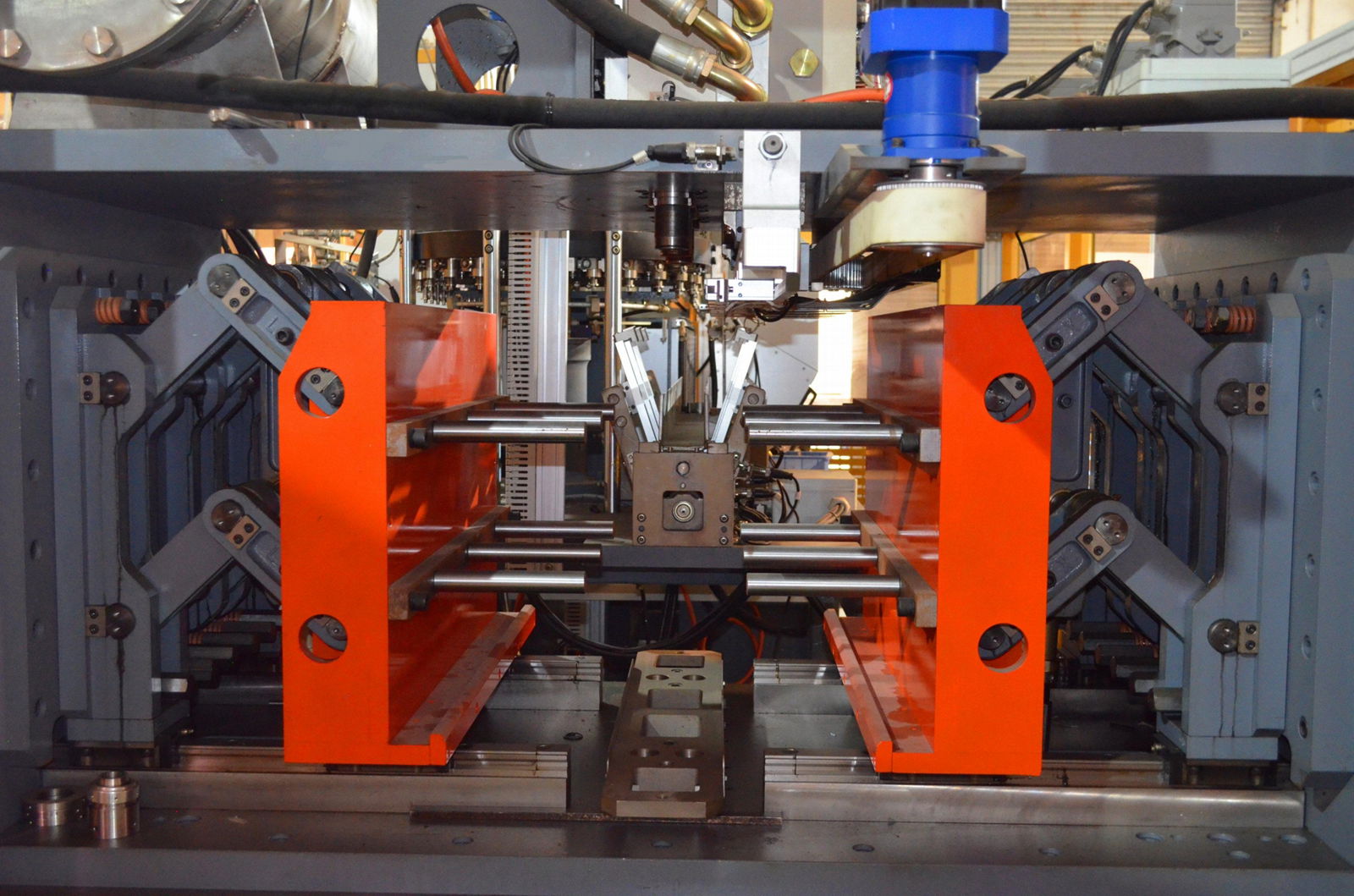

LXG1/20 700BPH 20L High Speed Auto Bottle Blowing Machine(6 Cavities)

Product Description

LXG- 2/20 Auto Bottle Blowing Machine Feature

1.1 Preform Feeding & Handling system

- Continuous preform feeding system

- Proper preform stabilization time on star-wheel before spindle insertion

- Composite aluminum alloy chain: strong, no wear, low maintenance cost

- Self-lubricate bushing and sealed bearing

- Ejection system for oval or not well inserted preforms

- Quick-change system (option) in less than 5 minutes for different neck diameters: change of loading wheel and loading guides

1.2 Preform Heating System

- Perfect heating system design helps decrease the power consumption.

- Special oven design helps power saving and is easy maintain.

- Preform heating system with laminar flow.

- Low thermal inertia: higher heating process consistency and fast start-up

- Oven dimensions based on preform and max bottle size (from 8 to 16 lamps)

- Modular oven

- Adjustable position for neck change

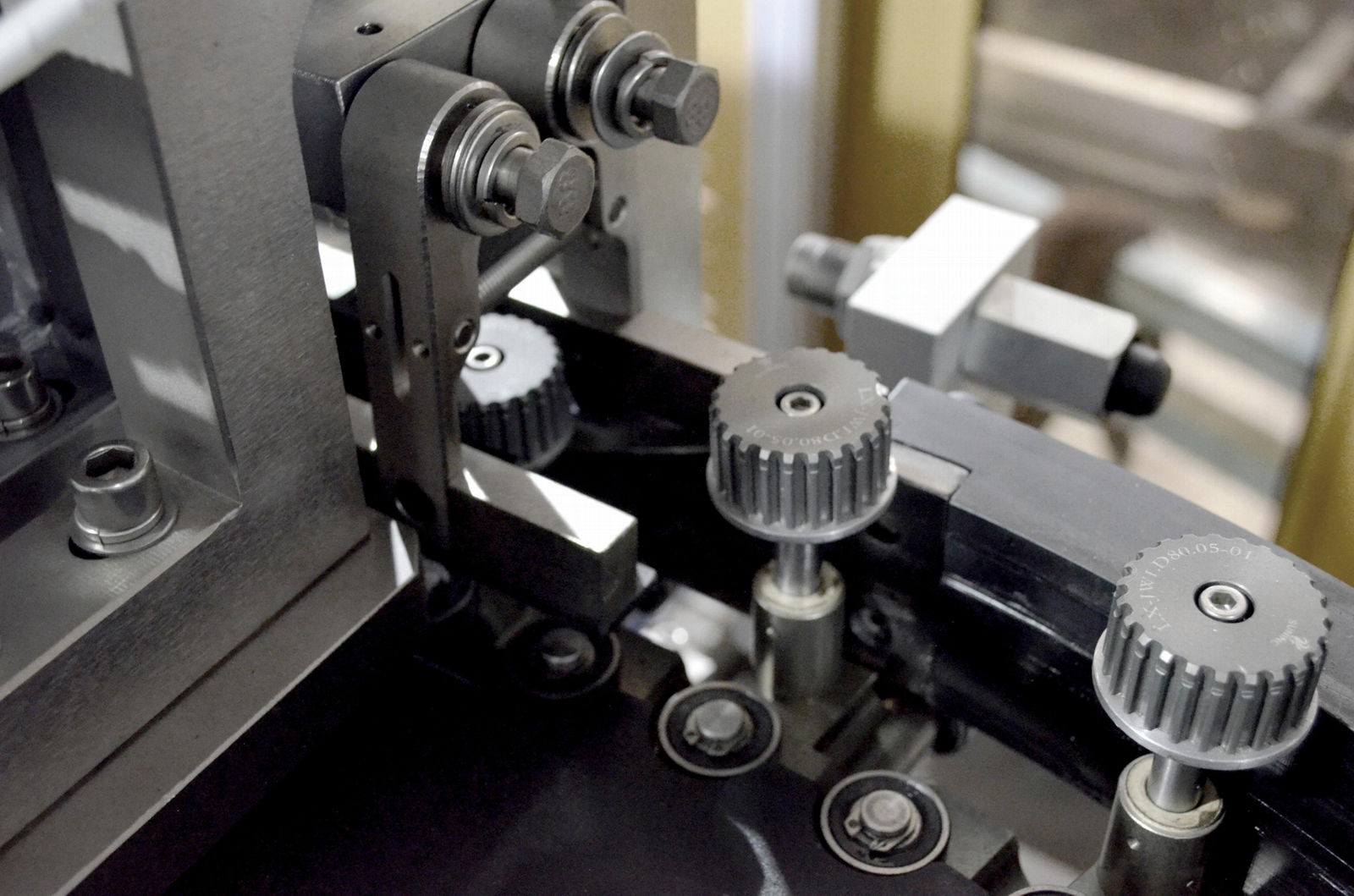

1.3 Preform Transfer & Pitch Change

- Servo-driven pitch-change system to optimize heating efficiency (oven pitch) and maximum bottle diameter (blowing pitch)

- Simple and reliable system

- Servo-driven unit for same-time preform and bottle transfer

- Precise and gentle preform holding

- Very high transfer speed

- Quick change of personalized parts (tool-less)

1.4 Stretching & Blowing

- Electrically driven blowing clamp, no oil

- Servo-driven motion with levers and oscillator

- High clamp speed

- Double-sided pneumatic compensation

- Servo driven stretch rods

- Fine setting of stretch profile thanks to servo control

- Blow seals, fast and independent for every cavity

- Self-learning of stretch stroke based on preform-bottle size

- High tech blowing valves: fast and independent for every cavity, with individual pre-blow flow regulation

- Very quick exhaust

- Standard Air tanks for peak blowing ramp, providing higher output

- By-pass valve to avoid chilled water when not in production

- Less power consumption once machine is in idle mode or is waiting for downstream

- No condensation on blow moulds once the machine is not blowing bottles

1.5 Bottle Ejection

- Servo-driven unit for bottle placed

- Can connect with air conveyor or belt conveyor or vacuum conveyor

- Bottle base cooling option

LXG-1/20 machine main parameter

|

|

Item

|

LXG-1/20

|

|

Main machine

|

Maximum Bottle capacity

|

20L

|

|

Maximum bottle diameter

|

Φ290mm

|

|

Neck diameter

|

Φ40~70mm

|

|

Maximum bottle height under neck

|

<500mm

|

|

Stretching stroke

|

<550mm

|

|

Clamping stroke

|

320mm

|

|

Bottom die stroke

|

50mm

|

|

Bottle pitch

|

400mm

|

|

Maximum output rate (bph)

|

700

|

|

Number of molds

|

1

|

|

Heating part

|

Number of heating modules

|

6

|

|

Number of heating lamps

|

12

|

|

Number of preform bases

|

44

|

|

Electric part

|

Voltage

|

380V

|

|

Frequency

|

50Hz

|

|

Service power

|

30~60kw/h

|

|

Installation power

|

150kw

|

|

Air source

|

High pressure

|

3.5Mpa

|

|

High pressure air consumption

|

9m³/min

|

|

Chilled water

(Water temperature ≤30℃)

|

Pressure

|

4bar

|

|

Flux

|

6m³/h

|

|

Weight

|

G.W.

|

Around 7,000kg

|

|

Dimension

|

Main machine (L×W×H)

|

3600×2100×3300mm

|

|

Preform unscrambler(L×W×H)

|

3200×2500×3400mm

|

|

Remarks:

* 600bph output rate base on 15L round water bottle.

* High pressure air consumption depends on PET bottle volume, altitude etc.

* With high-pressure air recycle system.

Main electric component list

|

No.

|

Name

|

Origin

|

Brand

|

|

Electric/control component

|

|

1

|

PLC

|

America

|

AB

|

|

2

|

Servo motor

|

|

3

|

Servo driver

|

|

4

|

Intermediate relay

|

|

5

|

Touch screen

|

|

6

|

Contactor

|

France

|

SCHNEIDER (TE)

|

|

7

|

Button

|

|

8

|

Air switch

|

|

9

|

Preform-infeed checking

|

Taiwan

|

RIKO

|

|

10

|

Switching power supply

|

Taiwan

|

MV

|

|

11

|

Heating module

|

Germany

|

SEMIKRON

|

|

12

|

Magnetic switch

|

Germany

|

FESTO

|

|

Valves/adaptor

|

|

1

|

Pre-blowing valve

|

UK

|

NORGEN

|

|

2

|

2nd blowing valve

|

|

3

|

Exhaust valve

|

|

4

|

One-way valve

|

|

5

|

Pressurizing clamping valve

|

|

6

|

Cylinder control valve

|

Germany

|

FESTO

|

|

7

|

Cylinder

|

|

8

|

Mold-closing lead rail

|

Taiwan

|

ABBA

|

|

Remarks: all above component are imported with original packaging. Longsun has the right to change the default parameter according to the marketing change or customer special requirement without further notification, a 5% change of the equivalent parameter will be allowable against the marketing trend and the spare parts supply condition!)

|

|

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,