| Model: | - |

|---|---|

| Brand: | ASTM F67/ASME SF67,ASME SA348,ASME SB265 Ti Alloys |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Products |

| Label: | Titanium Alloy , ASTM B265 , ASTM A348 |

| Price: |

US $3.2

/ kg

|

| Min. Order: | 5 kg |

| Live Chat: | Last Online:27 Jun, 2023 |

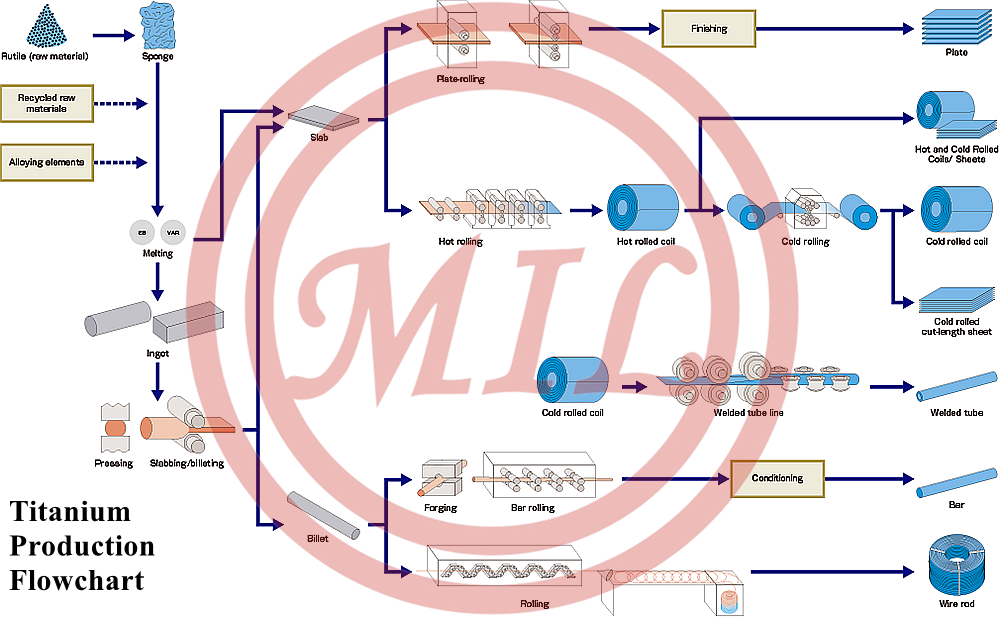

Titanium & Titanium Alloys

Titanium can be alloyed with iron, aluminium, vanadium, and molybdenum, among other elements, to produce strong, lightweight alloys for aerospace (jet engines, missiles, and spacecraft), military, industrial process (chemicals and petro-chemicals, desalination plants, pulp, and paper), automotive, agri-food, medical prostheses, orthopedic implants, dental and endodontic instruments and files, dental implants, sporting goods, jewelry, mobile phones, and other applications,

| Specification: | Description: |

| ASTM-F136 | Wrought Titanium-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) Alloy (UNSR56401) for Surgical Implant Applications |

| ASTM-F67 | Unalloyed Titanium for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700) |

| ASTM-F1108 | Ti6AL4V Alloy Castings for Surgical Implants (UNS R56406) |

| ASTM-F-620 | Alpha Plus Beta Titanium Alloy Forgings for Surgical Implants |

| ASTM-F1472 | Wrought Titanium-6 Aluminum-4 Alloy for Surgical Implant Applications (UNS R56400) |

| ASTM-F1341 | Unalloyed Titanium Wire UNS R50250, UNS R50400, UNS R50550, UNS R50700, for Surgical Implant Applications |

| ASTM-F1295 | Wrought Titanium-6 Aluminum-7 Niobium Alloy for Surgical Implant Applications (UNS R56700) |

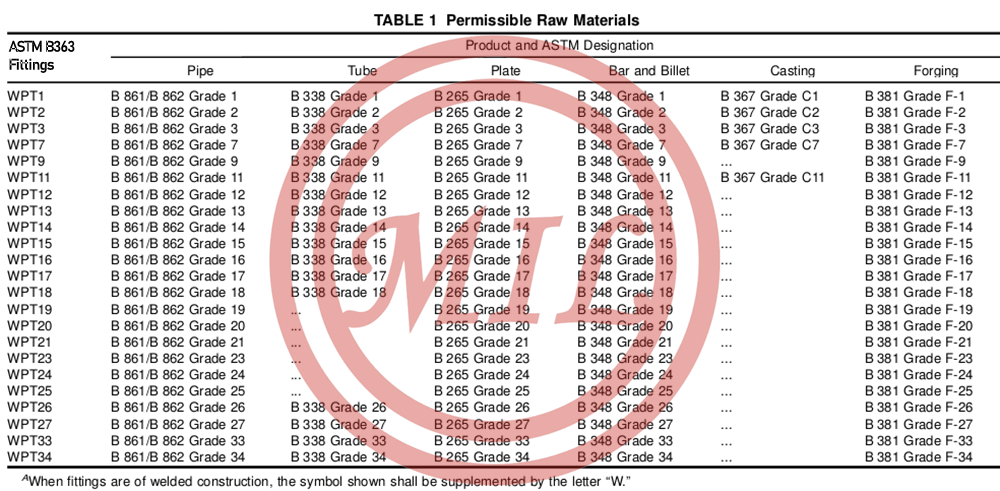

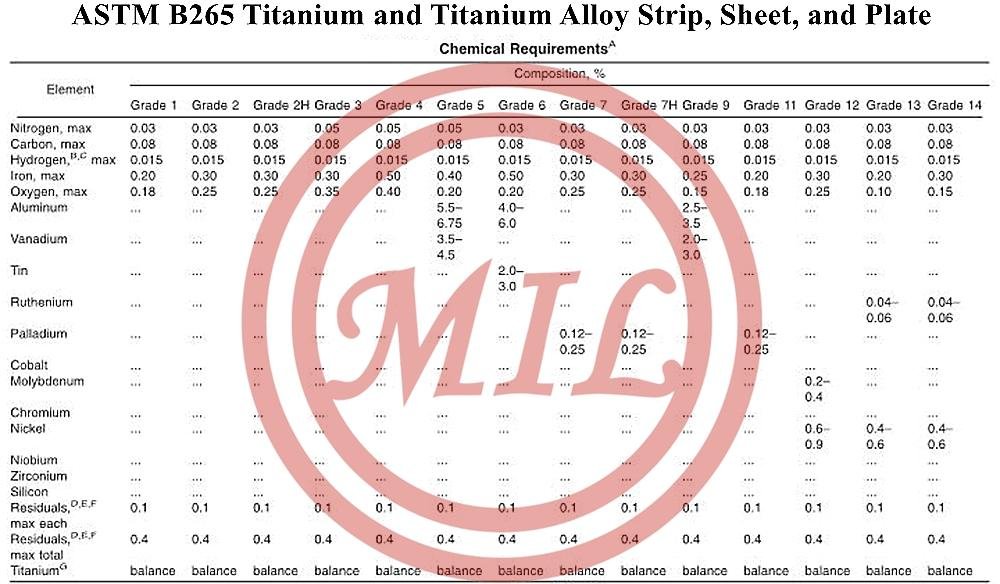

| ASTM B265 | Titanium and Titanium Alloy Strip, Sheet, and Plate |

| ASTM-B299 | Titanium Sponge |

| ASTM-B338 | Seamless and Welded Titanium &Titanium Alloy Tubes for Condensers & Heat Exchangers |

| ASTM-B348 | Titanium and Titanium Alloy Bars and Billets |

| ASTM-B363 | Seamless and Welded Unalloyed Titanium & Titanium Alloy Welding Fittings |

| ASTM-B367 | Titanium and Titanium Alloy Castings |

| ASTM-B381 | Titanium and Titanium Alloy Forgings |

| ASTM-B600 | Descaling and Cleaning Titanium & Titanium Alloy Surfaces |

| ASTM-B861 | Titanium and Titanium Alloy Seamless Pipe |

| ASTM-B862 | Titanium and Titanium Alloy Welded Pipe |

| ASTM-B863 | Titanium and Titanium Alloy Wire |

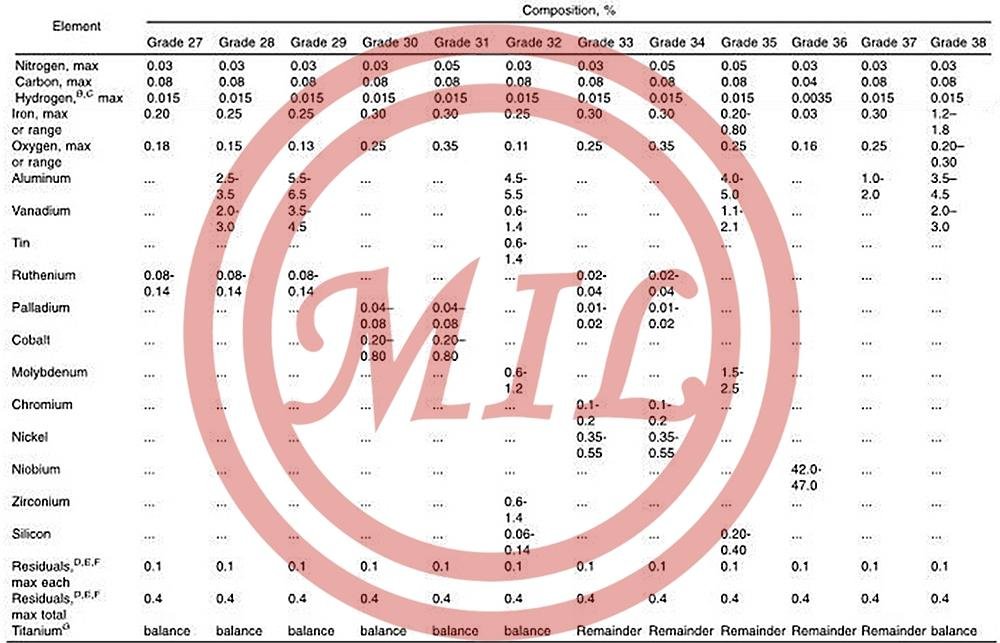

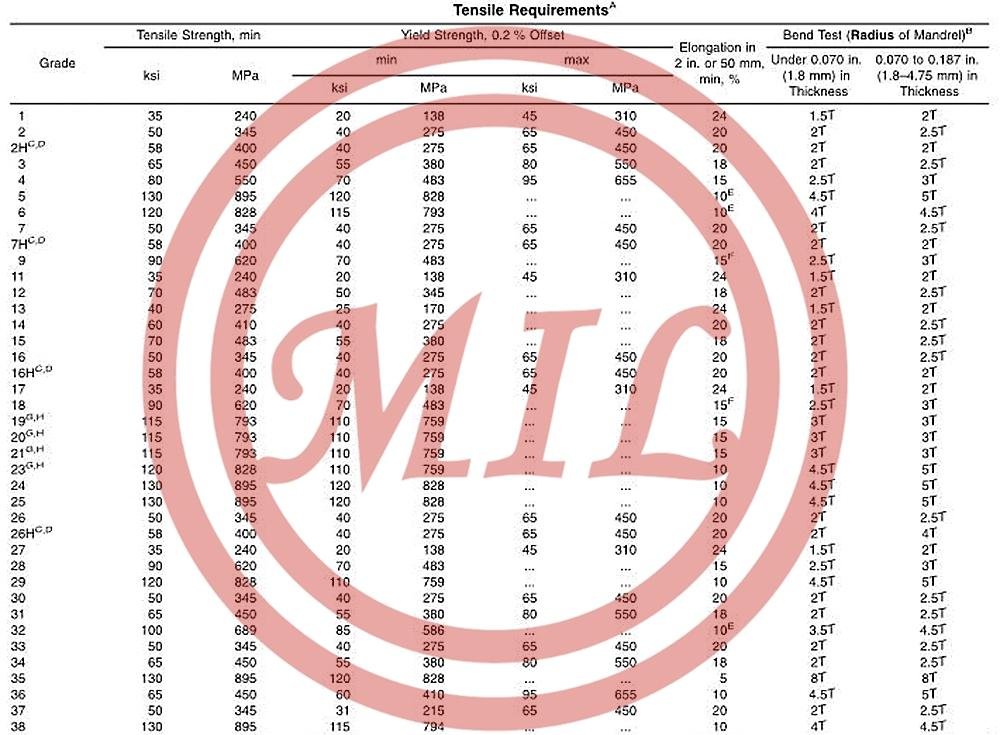

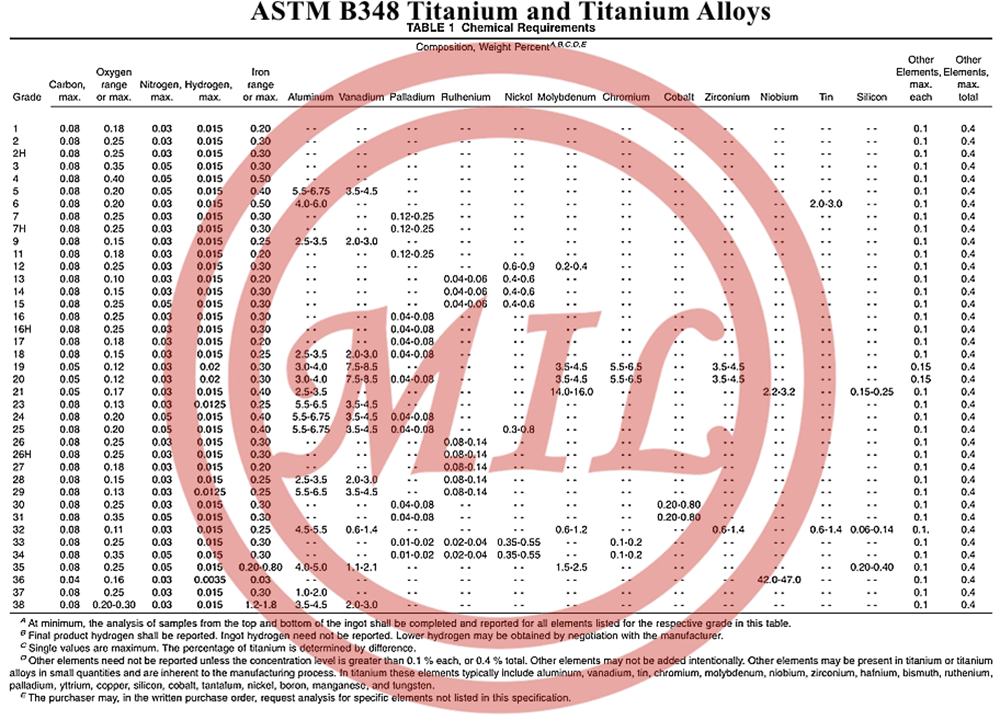

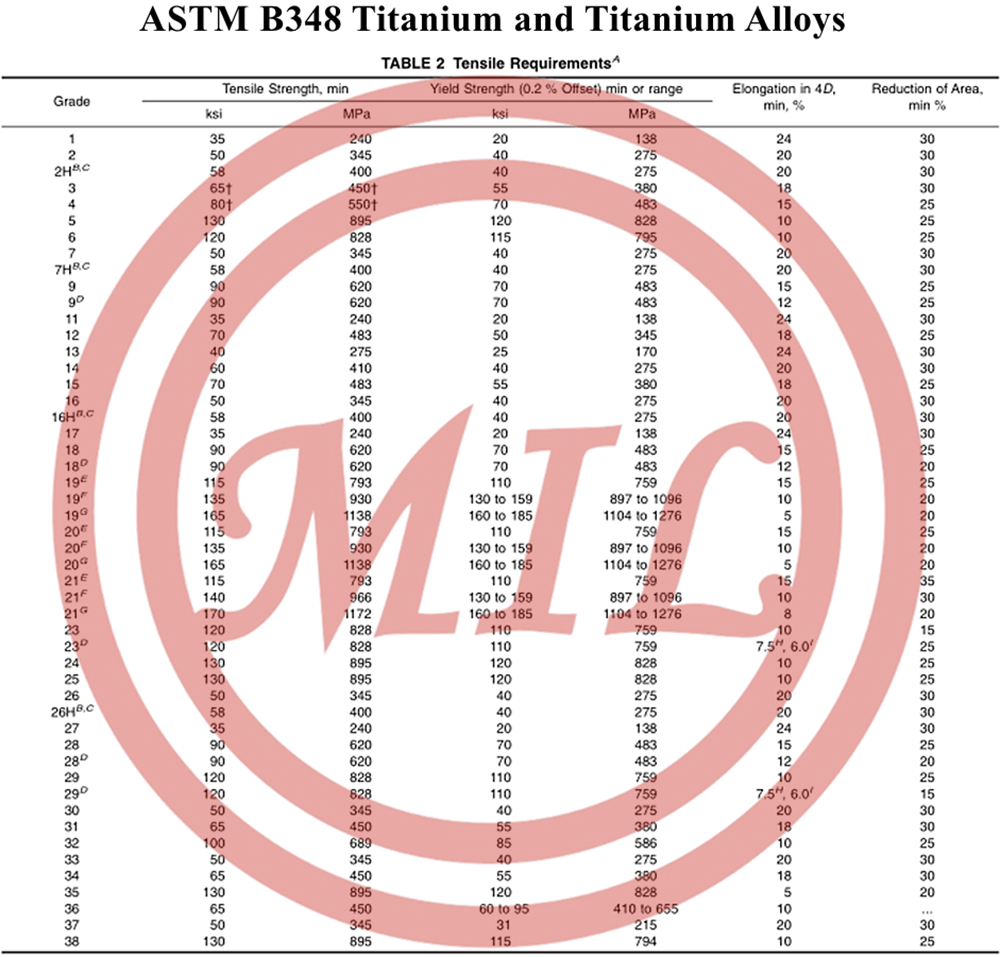

Titanium Metal Composition

| Grade | Description |

|---|---|

| Titanium Grade 1 | Unalloyed titanium, low oxygen, low strength |

| Titanium Grade 2 | Unalloyed titanium, standard oxygen, medium strength |

| Titanium Grade 3 | Unalloyed titanium, medium oxygen, high strength |

| Titanium Grade 4 | Unalloyed titanium, high oxygen, extra high strength |

| Titanium Grade 5 | Titanium alloy (6% aluminum, 4% vanadium) |

| Titanium Grade 7 | Unalloyed titanium plus 0.12% to 0.25% palladium, standard oxygen, medium strength |

| Titanium Grade 9 | Titanium alloy (3% aluminum, 2.5% vanadium), high strength. Mainly aerospace applications |

| Titanium Grade 11 | Unalloyed titanium plus 0.12% to 0.25% palladium, low oxygen, low strength |

| Titanium Grade 12 | Titanium alloy (0.3% molybdenum, 0.8% nickel), high strength |

| Titanium Grade 13 | Titanium alloy (0.5% nickel, 0.05% ruthenium), low oxygen |

| Titanium Grade 14 | Titanium alloy (0.5% nickel, 0.05% ruthenium), standard oxygen |

| Titanium Grade 15 | Titanium alloy (0.5% nickel, 0.05% ruthenium), medium oxygen |

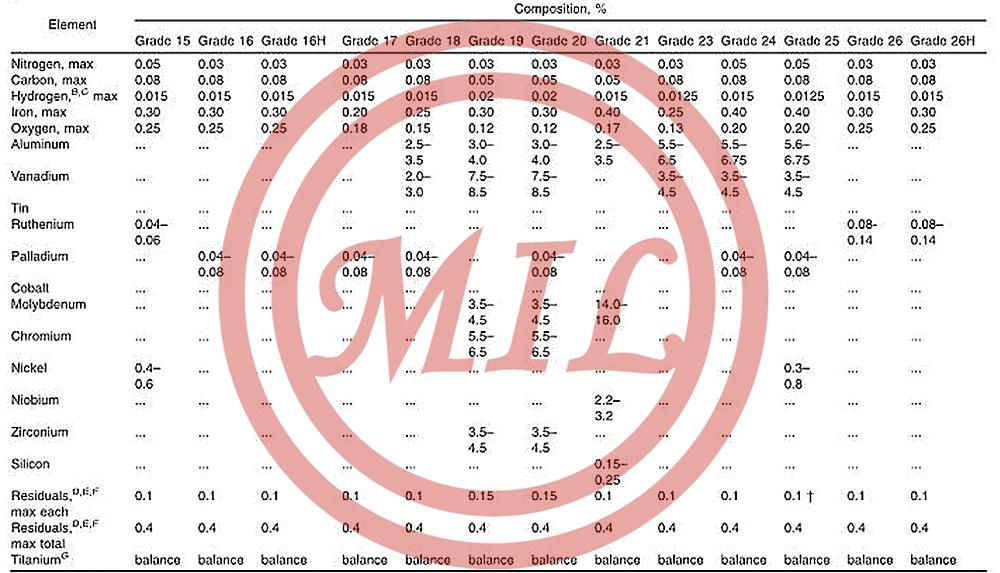

| Titanium Grade 16 | Unalloyed titanium plus 0.04% to 0.08% palladium, standard oxygen, medium strength |

| Titanium Grade 17 | Unalloyed titanium plus 0.04% to 0.08% palladium, low oxygen, low strength |

| Titanium Grade 18 | Titanium alloy (3% aluminum, 2.5% vanadium plus 0.04% to 0.08% palladium), |

| Titanium Grade 19 | Titanium alloy (3% aluminum, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum) |

| Titanium Grade 20 | Titanium alloy (3% aluminum, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum) plus 0.04% to 0.08% palladium |

| Titanium Grade 21 | Titanium alloy (15% molybdenum, 3% aluminum, 2.7% niobium, 0.25% silicon) |

| Titanium Grade 23 | Titanium alloy (6% aluminum, 4% vanadium, extra low interstitial, ELI) |

| Titanium Grade 24 | Titanium alloy (6% aluminum, 4% vanadium) plus 0.04% to 0.08% palladium |

| Titanium Grade 25 | Titanium alloy (6% aluminum, 4% vanadium) plus 0.3% to 0.8% nickel and 0.04% to 0.08% palladium |

| Titanium Grade 26 | Unalloyed titanium plus 0.08% to 0.14% ruthenium, standard oxygen, medium strength |

| Titanium Grade 27 | Unalloyed titanium plus 0.08% to 0.14% ruthenium, low oxygen,low strength |

| Titanium Grade 28 | Titanium alloy (3% aluminum, 2.5% vanadium) plus 0.08% to 0.14% ruthenium |

| Titanium Grade 29 | Titanium alloy (6% aluminum, 4% vanadium with extra low interstitial elements (ELI) plus 0.08% to 0.14% ruthenium |

Titanium Grade Overview

Titanium Grades and Alloys: Properties and Applications

Following is an overview of the most frequently encountered titanium alloys and pure grades, their properties, benefits, and industry applications. For specific terminology, please see our ‘definitions’ section at the end of this page.

Commercially Pure Titanium Grades

Grade 1

Gradie 1 titanium is the first of four commercially pure titanium grades. It is the softest and most ductile of these grades. It possesses the greatest formability, excellent corrosion resistance and high impact toughness.

Because of all these qualities, Grade 1 is the material of choice for any application where ease of formability is required and is commonly available as titanium plate and tubing. These include:

Chemical processing

Chlorate manufacturing

Dimensional stable anodes

Desalination

Architecture

Medical industry

Marine industry

Automotive parts

Airframe structure

Grade 2

Grade 2 titanium is called the “workhorse” of the commercially pure titanium industry, thanks to its varied usability and wide availability. It shares many of the same qualities as Grade 1 titanium, but it is slightly stronger. Both are equally corrosion resistant.

This grade possesses good weldability, strength, ductility and formability. This makes Grade 2 titanium bar and sheet are the prime choice for many fields of applications:

Architecture

Power generation

Medical industry

Hydro-carbon processing

Marine industry

Exhaust pipe shrouds

Airframe skin

Desalination

Chemical processing

Chlorate manufacturing

Grade 3

grade 3 titanium parts

Grade 3 Titanium Parts

This grade is least used of the commercially pure titanium grades, but that does not make it any less valuable. Grade 3 is stronger than Grades 1 and 2, similar in ductility and only slightly less formable - but it possesses higher mechanicals than its predecessors.

Grade 3 is used in applications requiring moderate strength and major corrosion resistance. These include:

Aerospace structures

Chemical processing

Medical industry

Marine industry

Grade 4

Grade 4 is known as the strongest of the four grades of commercially pure titanium. It is also known for its excellent corrosion resistance, good formability and weldability.

Though it is normally used in the following industrial applications, Grade 4 has recently found a niche as a medical grade titanium. It is needed in applications in which high strength is required:

Airframe components

Cryogenic vessels

Heat exchangers

CPI equipment

Condensor tubing

Surgical hardware

Pickling baskets

Titanium Alloys

Grade 7

Grade 7 is mechanically and physically equivalent to Grade 2, except with the addition of the interstitial element palladium, making it an alloy. Grade 7 possesses excellent weldability and fabricality, and is the most corrosion resistance of all titanium alloys. In fact, it is most resistant to corrosion in reducing acids.

Grade 7 is used in chemical processes and production equipment components.

Grade 11

machining grade 11 titanium

Grade 11 Titanium Machining

Grade 11 is very similar to Grade 1, except for the addition of a tiny bit of palladium to enhance corrosion resistance, making it an alloy. This corrosion resistance is useful to protect against crevice erosion and reducing acid in chloride environments.

Other useful properties include optimum ductility, cold formability, useful strength, impact toughness and excellent weldability. This alloy can be used in the same titanium applications as Grade 1, especially where corrosion is a concern such as:

Chemical processing

Chlorate manufacturing

Desalination

Marine applications

Ti 6Al-4V (Grade 5)

Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 titanium, is the most commonly used of all titanium alloys. It accounts for 50 percent of total titanium usage the world over.

Its usability lies in its many benefits. Ti 6Al-4V may be heat treated to increase its strength. It can be used in welded construction at service temperatures of up to 600° F. This alloy offers its high strength at a light weight, useful formability and high corrosion resistance.

Ti 6AI-4V’s usability makes it the best alloy for use in several industries, like the aerospace, medical, marine and chemical processing industries. It can be used in the creation of such technical things as:

Aircraft turbines

Engine components

Aircraft structural components

Aerospace fasteners

High-performance automatic parts

Marine applications

Sports equipments

Ti 6AL-4V ELI (Grade 23)

grade 23 surgical titanium

Grade 23 Surgical Titanium

Ti 6AL-4V ELI, or Grade 23, is the higher purity version of Ti 6Al-4V. It can be made into coils, strands, wires or flat wires. It’s the top choice for any sort of situation where a combination of high strength, light weight, good corrosion resistance and high toughness are required. It has a superior damage tolerance to other alloys.

These benefits make Grade 23 the ultimate dental and medical titanium grade. It can be used in biomedical applications such as implantable components due to its biocompatibility, good fatigue strength and low modulus. It can also be used in detailed surgical procedures, as:

Orthopedic pins and screws

Orthopedic cables

Ligature clips

Surgical staples

Springs

Orthodontic appliances

In joint replacements

Cryogenic vessels

Bone fixation devices

Grade 12

grade 12 titanium applications

Grade 12 Titanium Applications

Grade 12 titanium holds an “excellent” rating for its high quality weldability. It is a highly durable alloy that provides a lot of strength at high temperatures. Grade 12 titanium possesses characteristics similar to 300 series stainless steels.

This alloy can be hot or cold formed using press brake forming, hydropress forming, stretch forming or drop hammer method. Its ability to be formed in a variety of ways makes it useful in many applications. This alloy’s high corrosion resistance also makes it invaluable to those manufacturing equipment where crevice corrosion is a concern. Grade 12 can be used in the following industries and applications:

Shell and heat exchangers

Hydrometallurgical applications

Elevated temperature chemical manufacturing

Marine and airfare components

Ti 5Al-2.5Sn

Ti 5Al-2.5Sn is a non-heat treatable alloy that can achieve good weldability with stability. It also possesses high temperature stability, high strength, good corrosion resistance and good creep resistance. Creep refers to the phenomenon of plastic strain over long periods of time, which happens at high temperatures.

Ti 5Al-2.5Sn is mostly used in aircraft and airframe applications, as well as cryogenic applications.

Titanium Grade 16

Titanium Gr.16 is a “lean palladium” option that offers similar corrosion resistance to titanium grade 7 as a reduced cost due to less palladium alloy included. It is corrosion-resistant and used in a variety of industries, including:

| Titanium Alloy Classification |

| According to the relationship between the phase composition of the titanium alloy after quenching from the β phase region and the content of β stabilizing elements, titanium alloys are divided into 6 types. |

| α-type titanium alloy |

| Including industrial pure titanium and alloys containing only α-stabilizing elements; |

| Near alpha titanium alloy |

| Alloys with β-stabilizing element content less than C1; |

| Martensitic α+β titanium alloy |

| The alloy with β stabilizing element content from C1 to Ck referred to as α+β titanium alloy; |

| Nearly metastable β-type titanium alloy |

| β-stabilizing element content from Ck to C3 alloy referred to as near β-type titanium alloy; |

| Metastable β-type titanium alloy |

| The alloy with β stabilizing element content from C3 to Cβ referred to as β-type titanium alloy; |

| Stable β-type titanium alloy |

| The alloy with β-stabilizing element content exceeding Cβ is referred to as a full β-type titanium alloy. |