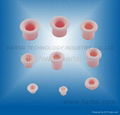

Tungsten Carbide Coil Winding Nozzle(Hard Alloy Coil Winding Nozzle)

Product Description

Description:

Tungsten carbide wire guide nozzles(Coil winding nozzles)used in coil winding machines to guide the wire to wind in the bobbin, pins and etc. For the manufacture of coils, motors, transformers, relays, inductance and sensors in automotive, telecoms, electric and electronic applications.

Features:

1. High Wear Resistance

This is assured by the choice of materials for wear elements possessing a minimum hardness in excess of Vickers 1, 000 (HRC 70).

2. Scratch-Proofing

Eliminate wire insulation film damage, low friction resistance, stable wire tension. The wire-guiding surfaces are mirror finished by diamond lapping to a surface roughness of 2 -4 micro inches Ra or better, material permit.

3. Straightness and Stiffness

Straightness and Stiffness are defined by the wire exit being concentric and inflexible with respect to the nozzle locating? . In plain terms, the wire should exit from the nozzle concentric to the locating? To within 0.02 mm, with or without load. A geometric characteristic presentation is shown at upper left. Concentricity to within 0.01mm.

4. Precise Exit Radii

Because the coil winding nozzle's Exit Radii governs the angle of the wire exit from one coil to the next, it should be monitored to + / - 0.025 mm. This is done by digital measurement, shown at upper right.

Specification:

Measurements:

Customize available by requested, outside diameter is governed by nozzle wall thickness. See the measurements drawing to confirm your nozzles measurements according to your winding machine and coil products.

Product Image

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,