| Model: | - |

|---|---|

| Brand: | Spark |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | - |

| Price: |

US $20

/ pc

|

| Min. Order: | 10 pc |

| Live Chat: | Last Online:28 Sep, 2022 |

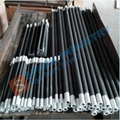

ANTI-OXIDANT PROPERTY OF ELEMENTS:

The silicon carbide heating element is a kind of non-metal high temperature electric heating element. It is made of selected super quality green silicon carbide as main material, which is made into blank, silicided under high temperature and re-crystallized. Compared with metal electric heating element, this kind of element is characterized by high-applied temperature, anti- oxidization, anti- corrosion, long service life, little deformation, easy installation and maintenance. Therefore, it is widely used in various high temperature electric furnaces and other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass and machinery, etc.

We adopt new production process of cold ends, so our Sic heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends to damage the furnace body.

Specification

1. Name: SiC heating element

2. Type: ED, DB, Shape SC, SCR, U, W

3. Production process: Made into blank, silicided under high temperature and re-crystallized.

4. Character: High-applied temperature, anti-oxidization, anti-corrosion, long service life, little deformation, easy installation and maintenance.

Advice of using the element

1. In order to keep furnace temperature and the charges uniform of each element, before installation resistance distribution must be carried.

2. As the element is very brittle, be careful while install and maintain to avoid any damage.

3. When start to operate the furnace, raise voltage slowly and gradually, never give full load at one time.

Usage

Used in various high temperature electric furnaces and other electric heating devices, such as in the industries of magnet, ceramics, metallurgy, glass, and machinery.

The choice of heating element depends on many factors. For example, silicon carbide elements are capable of higher operating temperatures and higher watt loadings than say metallic elements. They are self-supporting and can be used in furnaces either too wide or too long to be spanned by other element types and are relatively easy to change while hot. Silicon carbide heating elements are used extensively in brazing and sintering furnaces running continuously at or above 2050°F (1120°C) and for other processes where the temperature range lies between 2375°-2725°F (1300°-1500°C).

| Payment Terms: | TT / LC / PayPal |

|---|---|