| Model: | - |

|---|---|

| Brand: | GELGOOG |

| Origin: | Made In China |

| Category: | Agriculture & Foods / Processed Food / Processed Vegetable |

| Label: | tomato sauce maker , ketchup plant , sauce productn line |

| Price: |

¥5000

/ pc

|

| Min. Order: | 1 pc |

| Live Chat: | Last Online:14 Dec, 2021 |

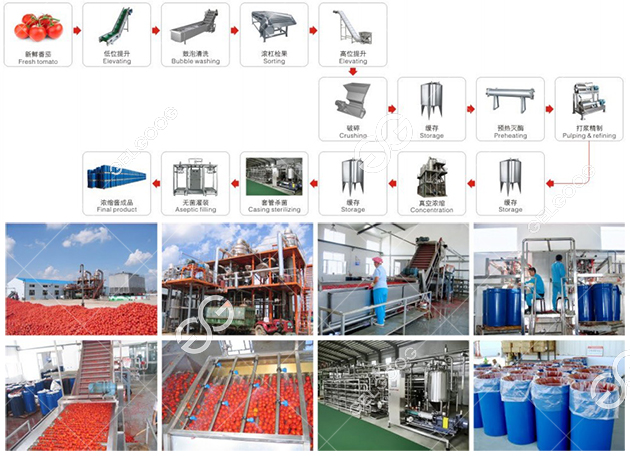

Introduction of the tomato paste production

Tomato paste production line equipment includes raw fruit lifting system, cleaning system, sorting system, crushing system, preheating enzyme system, beating system, vacuum concentration system, sterilization system, aseptic big bag filling system, glass bottle filling system, Can filling system, secondary pasteurization machine, labeling machine, coding machine, packaging machine, etc.

Tomato paste equipment production line parameters:

Raw material: fresh tomatoes

End product: tomato sauce (concentration is 28-30%, 30-32%, 36-38%)

Processing capacity: 10~1500T fresh fruit/day

Jam ingredients: pure fruit puree, vitamins, sugar and other flavor additives.

Sterilization method: pasteurization, UHT high temperature sterilization, ultra high temperature sterilization. (Adjustable according to requirements)

Terminal packaging: aseptic vat, bag-in-box aseptic pouch, tinplate small package, small bag packaging.

Control method: manual control or automatic control can be used.

Tomato paste production line main features:

Tomato Paste Production Line Operation points:

Tomato Paste Production Line Operation

Step one: Cleaning

The tomatoes are uniformly placed in a container. Worker turns on the water tap. Tomatoes are driven by water to remove mixed impurities.

Step 2: Washing :

Plenty of fresh tomatoes enter the washing machine. The washing machine uses a bubble design to reduce the impact of tomatoes. Keep the tomatoes intact.

Step 3: Picking

After the cleaning is completed, the workers will pick out the bad tomatoes in time to avoid going to the next process.

After the tomato sauce has been cleaned, the tomato sauce comes to the sauce.

Step 4: Crushing

Before beating, we need to process the tomatoes in advance. Crush the tomatoes with the help of a coarse shredder.

Step 5: Preheating

Made of stainless steel 304, used for pre-heating inactivation of crushed tomato particles. It can protect the color and taste, and improve the pulping rate.

Step 6: Pulping

The kneaded tomato will automatically filter out the coarse and hard substances such as tomato skin and seeds by the ketchup equipment.

Step 7: Canning

The canning step, that is, filling the ketchup into a jar. Good canning preserves ketchup more. Extend the shelf life of ketchup.

After the ketchup is packed, it comes to the sealing step. One in and one out, the production is complete.

Step 8: Metal Detection

The contactor on the assembly line mainly tests whether the bottle is filled with ketchup, because in the factory production, if there is a mechanical failure resulting in missed installation, it is difficult for personnel to find, and it can only be detected by such a contactor. The yellow component next to the assembly line is a proximity switch that detects the passage of the tomato can.

Step 9: Packaging

Packing specifications are every six barrels, and every six barrels are neatly arranged. The packaging machine will automatically wrap the plastic packaging around the tomato bucket ~ At this time, it will pass through the high temperature area.

Step 10: Labeling

After passing through the high temperature zone, the plastic has been attached to the ketchup can. This is followed by an automatic labeling machine to label the passing tomato package. That’s it for ketchup.

Tomato paste processing production line operation points:

1. The acceptance of raw materials is based on the requirements of special varieties for processing. Yellow, pink or light-colored varieties shall not be mixed, and fruits with green shoulders, stains, cracked fruits, damage, umbilical rot and insufficient maturity shall be excluded. And those with uneven coloring and lighter fruit proportions should be removed by flotation during fruit washing. Pick the fruit, remove the stalk and wash the fruit first, and then spray it with water to keep it clean. Tomato stalks and sepals are green and smelly, affecting color and flavor. When removing the stalk, trim the green shoulders and spots, and remove the tomatoes that are not suitable for processing.

2. Crushing and removing seeds. The crushing means that it is heated quickly and evenly during pre-cooking. The removal of seeds is to prevent the seeds from breaking during beating. If mixed into the pulp, it will affect the flavor, texture and taste of the product. For crushing and removing seeds, use a double-leaf crusher, and then use a rotary separator (hole diameter 10 mm) and a deseed device (hole diameter 1 mm) to remove seeds

3. Pre-cooking, beating and pre-cooking make the tomato puree after crushing and de-seeding is quickly heated to 85℃~90℃ to inhibit the activity of pectin lipase and abundance of lacturonidase, so as not to reduce the price and denaturation of pectin. Reduce the viscosity and spreadability of the sauce. After pre-cooking, the puree enters the three-pass beating machine. The material is hit by a high-speed rotating scraper in the beating machine to become a slurry. The slurry passes through the circular sieve by centrifugal action.

4. Ingredients and concentration require different concentrations of the sauce body according to the type and name of the ketchup. The product is directly concentrated from the puree after beating. Atmospheric concentration means that the material is concentrated in an open jacketed pot, and the material is concentrated in a vacuum state of 600 mm ~ 700 mm. The temperature of the material is 50 ℃ ~ 60 ℃. The color and flavor of the product are good, but the equipment investment is expensive. The end point of tomato paste concentration is determined by a refractometer. The concentration can be terminated when the measured product concentration is 0.5% to 1.0% higher than the specified standard.

The tomato paste production line is heated and canned. The concentrated sauce must be heated to 90℃~95℃ and then canned. Containers include tinplate cans, toothpaste-shaped plastic bags, and glass bottles. Plastic cups or toothpaste-shaped plastic tubes are used to put the tomato paste The company is packaged as a seasoning. After filling the can, it will be vented and sealed immediately.

7. The temperature and time of tomato paste sterilization, cooling and sterilization are determined by the heat transfer property of the packaging container, the filling quantity and the concentration and rheology of the sauce body. After sterilization, tinplate cans and plastic bags are directly cooled with water, while glass bottles (cans) should be gradually cooled down in sections to prevent the container from breaking.

| Payment Terms: | T/T,L/C |

|---|---|