| Model: | - |

|---|---|

| Brand: | BendasKing |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | ceramic tile mold , tiles mold assembly , ceramic tile mould |

| Price: |

US $7500

/ pc

|

| Min. Order: | 1 pc |

| Last Online:16 Jan, 2018 |

Low Price High-Intensity Steel Custom Made Ceramic Tiles Mold Assembly

|

|

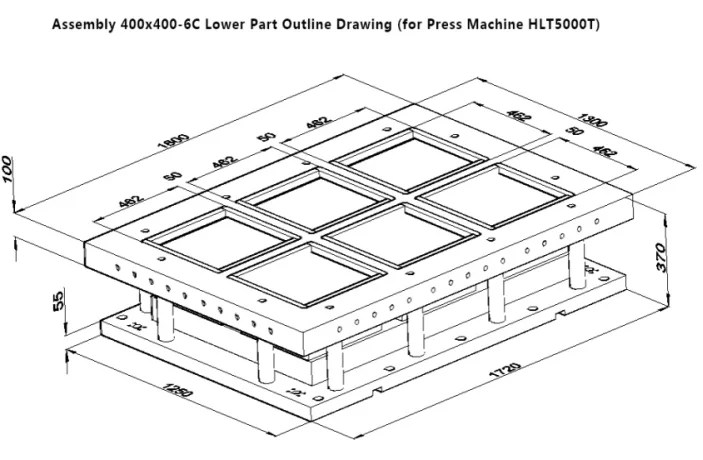

| Product Name | Custom Made Ceramic Tiles Mold Assembly |

| Material | 45# Steel + Wear Resistant Alloy Steel |

| Size | Custom made according to tile factory's Press Machine and actual situation |

| Cavity | 1C,2C,3C,4C,6C,8C,etc. Accroding to factory Press and Market needs. |

| Press Times | 200W-350W Times,according to customers needs. |

| Packing | Wooden Cases or As Request. |

YQ Benda Group - The Ceramic Tile Mould Manufacturer - is one of the leading manufacturer of ceramic tile mould assembly in China. Our products cover small external wall tile 20×20mm to big floor tile 1200×1200mm as well as various kinds of coal-dust brick and machinery parts. We keep the idea of innovation, commitment to providing the most suitable solution of the Ceramic Tile Mould Assemble for ceramic tiles manufacturers. Our aim is to make sure our customer be absolutely satisfied.

|

What make us proud is that since the founding in 1996, we have provided our products for more than 200 factories, produced mould assembly and master mould over a thousand sets. With our valuable production experience, professional knowledge and our consistent of high quality and process requirement to our product, we believe we can cooperate closely in order to design the most suitable mould assemble for you! |

|

Mould Assembly And TechnicalSolution - Made by YQ Benda Group

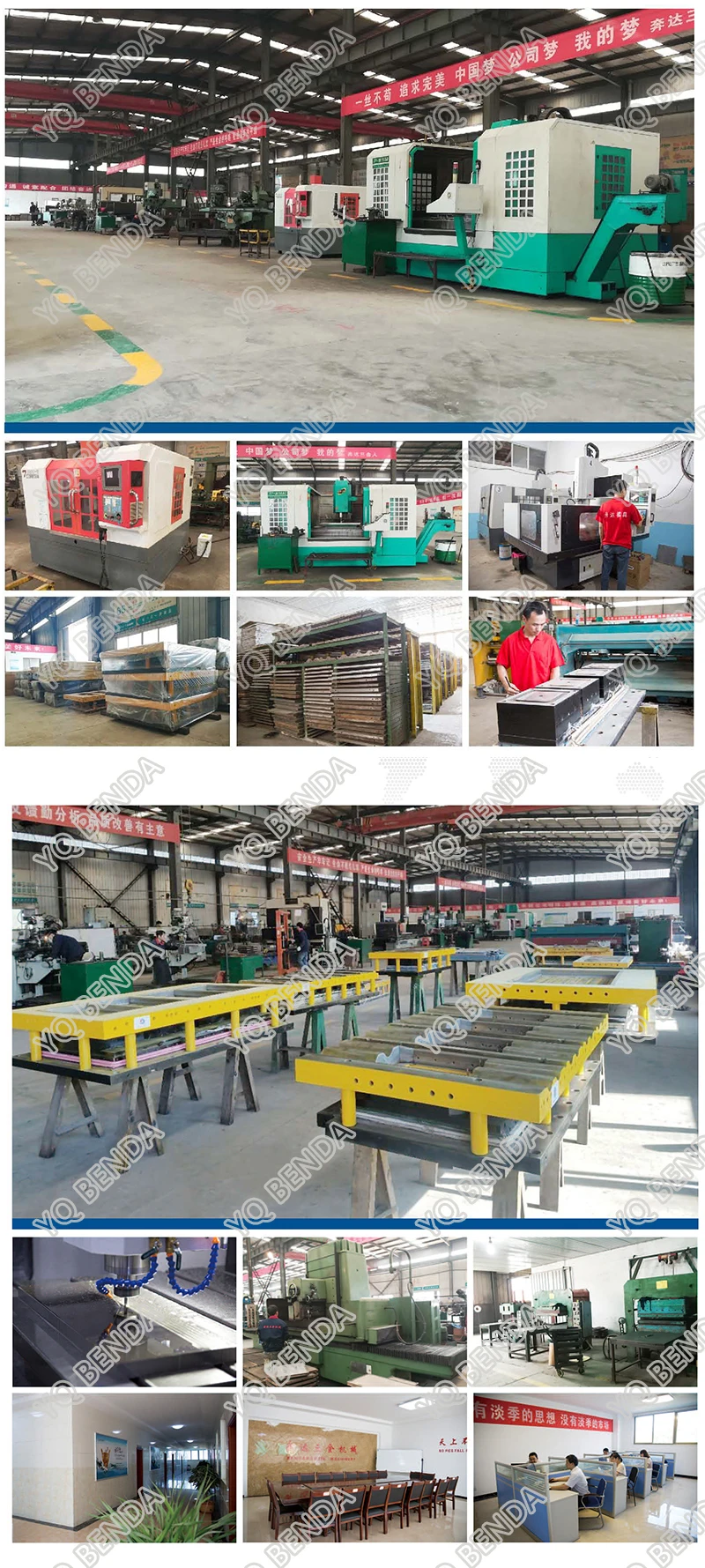

1.High Quality Steel, Advanced Equipment and Strict Management System.

2.Rich Production Experience and Professional Knowledge.

3.Stable Quality, Service and Product Performance.

4.The Most Attractive Cost-Effective and Total Cost Control.

5.Customized According To Ceramic Tile Factory.

6.Provide Design and Process Service For More Than 200 Ceramic Tile Factories.

|

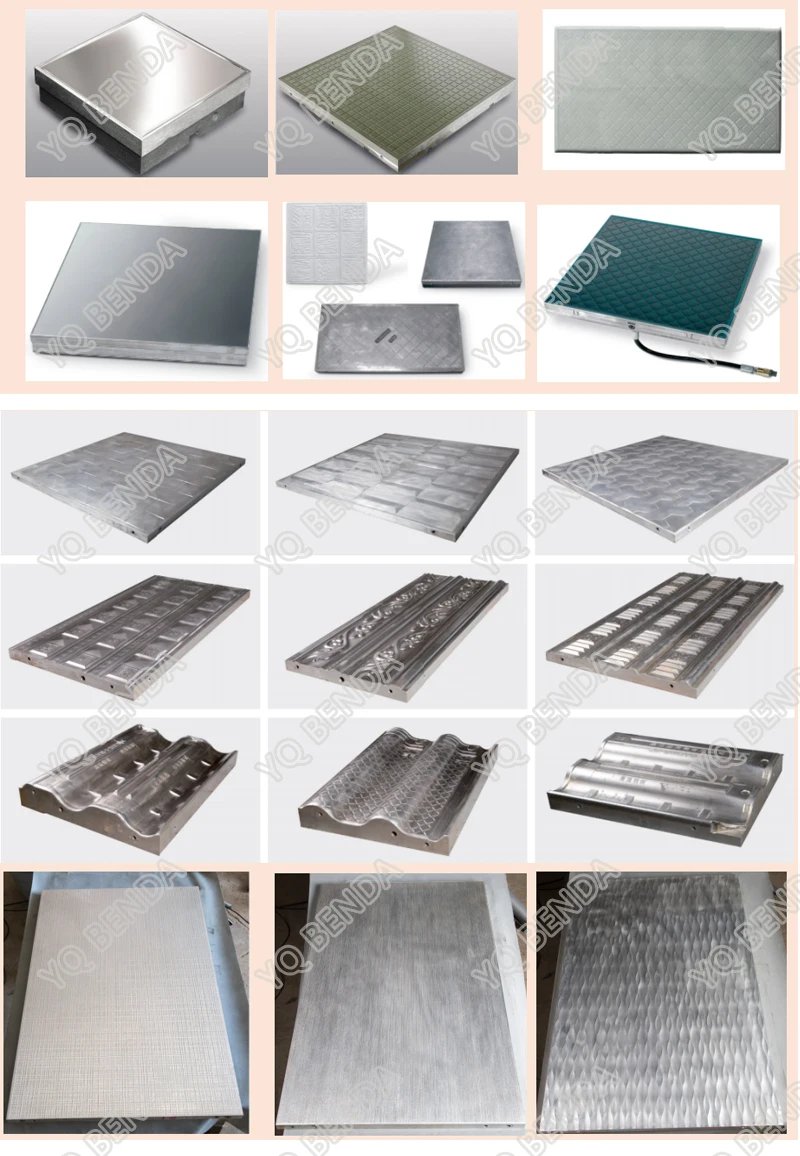

Floor Tile Mould Assembly 800x800mm-1C |

|

Floor Tile Mould Assembly 600x1200mm-1C |

|

Floor Tile Mould Assembly 600x600-2C |

|

Interior Wall Tiles Mould Assembly 300x400-4C |

|

Roof Tile Mould Assembly 300x400-4C |

|

Roof Tile Mould Assembly 230x370-5C |

Our sales representative and engineers will work hand-in-hand with our customers to manufacture innovative and suitable moulds assembly for your ceramic tiles manufacturing.Our mould assembly covers variety size ceramic tiles. No matter what’s the situation, there’s some key factors need to be clear for the basic designing.

| Press Model | ? |

| Tile Size | ? |

| Tile Thickness | ? |

| Shrinkage Rate | ? |

With above 4 information, our engineers will calculate the cavity quantity and design the mould assembly. When the information is not clear enough, we need pictures of press machine and worktable. In special cases,we arrange for engineers to do on-the-spot investigation and study in ceramic tile factories.

Design Demo.

(Demo)

Factory Display

Master Mould and Punch

Based on stable product quality, ultra-high cost performance and growing reputation, we have been working steadily with more and more ceramic tile manufacturers for over 20 years, developing over 1000 kinds of master dies for different customers.

Packing

Certificate

We have rich knowledge of ceramic tile mould production, first-class steel suppliers, advanced production equipment and over 20 years experience of ceramic tile mould production and serve more than 200 customers.

We have 5 ceramic tile mould production bases in China. Our product are all over China and gradually towards to the world.

With our stable product quality, ultra-high cost performance, continuous improvement and innovation of products and our employees and engineers’ rich experience, We have became the trusted partners of more and more tile factories. No matter what challenges is going to face, we look forward to working with you to create a brilliant future.

Contact US.

For more information regarding Custom Made Ceramic Tiles Mold Assembly,please don't hesitate to contact us.

Email: aaron(@)yqtenda.com

Mobile(Whatsapp):+86-18560273561

www.bendasanking.com