| Model: | FS85 100 130 |

|---|---|

| Brand: | Fangsheng |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | nylon extruder , plastic bag extruder , woven bags extruder |

| Price: |

¥30000

/ set

|

| Min. Order: | 1 set |

| Last Online:31 Jul, 2017 |

Waste nylon plastic woven bags recycling extruder machine

Brief introduction of Waste nylon plastic woven bags recycling extruder machine

This series plastic recycling machine have high effectively exhausting, filter, screen changer.

Material is cut, pre-dried, pre-heated, pre-homogenized and compacted in the Compactor/shredding drum.

Many materials can be precessed directly without need of the upstream pre-shredding, resulting in a dramatic reduction in operaional costs.

Less power consumption cost per kilogram, high output, reduced floor space occupation, easy to operate.

Advantages of the machine

1. Screw and barrel are made of 38CrMoAlA, inlet mouth treated with special alloy: very strong and long life.

2. Easy operation: it has automatic constant temperature control and stable performance. After adjusting well, 1 or 2 workers are enough to run this machine, to feed the materials and change pellet receiver.

3. Low cost in using after redesign: now this kind machine is more economic in electric power source and also water. In the long working life of this machine, it can save many sources in energy!

4. High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.

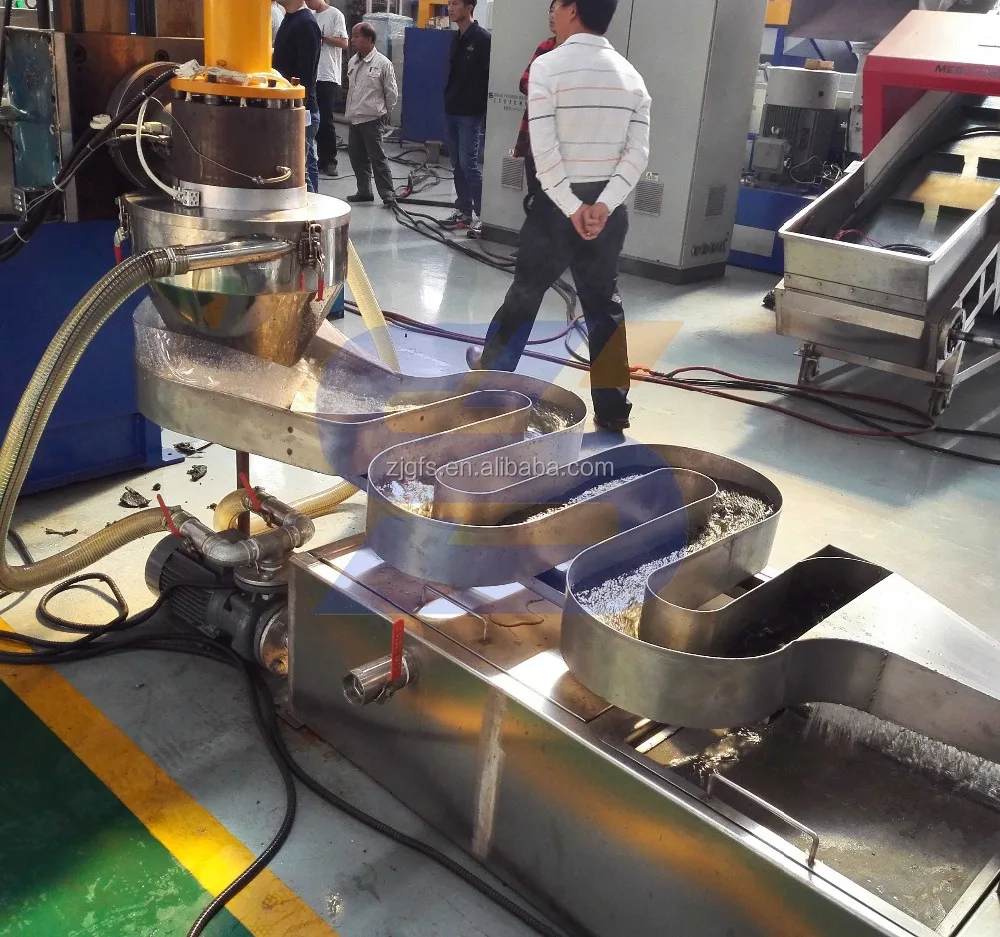

Images of the machine

|

FS series double-stage pe pp film compactor-granulator machine (with agglomerator) |

|||||

|

Model |

FSDJ-85/85 |

FSDJ-100/100 |

FSDJ-130/130 |

FSDJ-160/160 |

FSDJ-180/180 |

|

Screw Dia.(mm) |

85 |

100 |

130 |

160 |

180 |

|

L/D Ratio |

25-42 |

25-42 |

25-33 |

25-33 |

25-33 |

|

Output(kg/hr) |

120-180 |

250-350 |

400-500 |

550-700 |

800-1000 |

|

FS series single-stage pe pp film compactor-granulator machine (with agglomerator) |

||||||

|

Model |

FSSJ-70 |

FSSJ-85 |

FSSJ-100 |

FSSJ-130 |

FSSJ-160 |

FSSJ-180 |

|

Screw Dia.(mm) |

70 |

85 |

100 |

130 |

160 |

180 |

|

L/D Ratio |

25-42 |

25-42 |

25-42 |

25-3 |

25-33 |

25-33 |

|

Output(kg/hr) |

120-180 |

180-250 |

250-350 |

400-500 |

550-700 |

800-1000 |

Certification

Workshop and factory show

Exhibition

1.Delivering the goods on time.

2.We provide 12-24 months warranty after goods arrive, we respond your complain within 48hours.

3.We promise all spare parts available in lifetime use.

4.We are a sales team, with all techinical support from engineer team

FAQ

1. Are you manufacturer or trading company?

Answer: we are manufacturer,all the machine ,we make it ourself to reduce the cost of our customer.

2. The quality of the machine is good?

Answer: All the machines are manufactured with high quality, we choose our material very strict,

all the material come to our factory must pass the test. Substandard goods are returned to the supplier.

3. Why choose us?

Answer: That is a frequent question,we take strong attention to every detail in the manufacturing process,the quality control in our factory is very strict,all defective semi-manufactures must be treated again or reject.

If you are interested in our other products, you can click on the following pictures.