| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Pumps Vacuum Equipment |

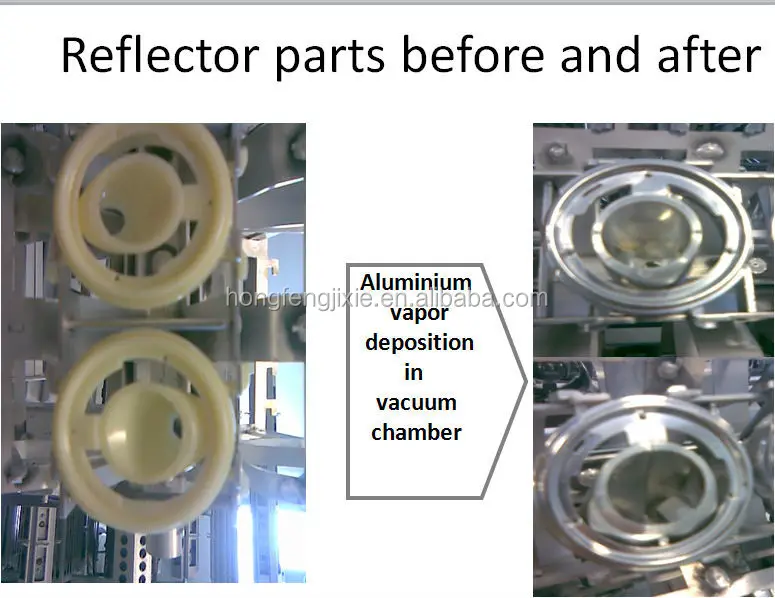

| Label: | glass coated machine , vacuum coating plant , vacuum metalizing |

| Price: |

US $30000

/ pc

|

| Min. Order: | 1 pc |

| Live Chat: | Last Online:19 Jul, 2017 |

Quick Details

Packaging & Delivery

| Packaging Details: | Export Standard Packing |

|---|---|

| Delivery Detail: | Shipped in 60 days after payment |

vacuum deposition unit for metalization

[We provide technical consulting service and modification solution for old machines]

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Product Description

| Parts Name | Vacuum evaporation aluminum coater | Vacuum magnetron sputtering system | Vacuum arc deposition machinery |

| * Main application | Plastic or glass metallizing, decorative coatings | High quality plastic metallizing;

mirror making; ITO conductive glass, Low-E glass and sun reflecting glass; silvering for disposable plastic culteries; Solar glass tubes; tools coating; other thin film coating. |

Tools coating;

Decorative coatings on metal parts(e. g. Stainless steel sheet); Golden coloring on ceramic tiles, jewelry, watch parts, glass bottles; Other substrates which can bear high temperature up to 600 centigrade. |

| * Custom made working chamber in rectangular or cylindrical | Single layer | Single layer or with cooling jacket | Single layer or with cooling jacket |

| * Base material of body | Carbon steel or stainless steel | Carbon steel or stainless steel | Stainless steel |

| * Custom made carousel/rack/jigs | √ | √ | √ |

| * High vacuum system based on oil diffusion pumps or molecular pump, booser pump and mechanical pumps; | √ | √ | √ |

| * Electrical controlling center with PLC screen, automatic and manual work modes available; | √ | √ | √ |

| * Tungsten&aluminum filament evaporation unit | √ | × | × |

| * Magnetron sputtering cathodes in rectangular or cylindrical | × | √ | × |

| * Arc deposition unit | × | × | √ |

| Notice: This is a kind of custom made machine, the three above unit can be united in the same machine for multi-functional applications. | |||

| * Power support | Evaporation transformer | Magnetron sputtering source | Arc source |

| * Gas feeding system | × | √ | √ |

| * Cool water | For pumps | For pumps and cathodes | For pumps, cathodes |

| * Compressed air needed | √ | √ | √ |

Advantages

Advantages of this machine(vacuum PVD coater):

1) Simple visual interface for the operator, process control system runs on Windows system interface and easy to use

2) Vacuum pump system efficiency, which increases productivity due to shorter batch times

3) High performance layer monitoring system is equipped for enhanced production result

4) Automated work cycle, which requires less workers per shift and training time, low production cost

5) Repeatable and reliable coating

6) Safter and Environmentally-friendly process guarantee

7) Highest yield

Coating properties:

• Excellent layer properties

• Longer lifetime

• Smooth surface

• Many bright, metallic colours, decorative or functional

• Excellent scratch protection

Our Services

Before sales:

After-sales

-------------------------------------------------------------------------------------------------------------------------------------------

Processing Center:

-------------------------------------------------------------------------------------------------------------------------------------------

Order Processing

Packaging

When the machine is shipped, it is in un-assemble condition.

The packing is made up of steel, polywood sheet and thin fim, as well as pallet.

The solid packing can make sure you will receive a machine without destroy.

FAQ

Question 1: What is price of the machine?

Answer:

The machine is custom made. If you have any drawing or any information on specification of the machine, please send to us for quote.

If you are totally new in this area, please tell us the max. dimension of your products, its application, and your desired capacity.

We will provide our professional s estions and work out an appropriate design for your project.

Question 3: What do I have to do for my products before processing by the vacuum coater?

Answer: In vacuum area, the products(we call it"substrate") have to be CLEAN, DRY AND SMOOTH. So we will need washer and dryer, sometimes base varnish, and topcoat to protect the coatings.

Question 2: Do I have to pay the costs for pollution?

Answer:

The machine is environment-friendly, there is no liquid chemical waste and harmful gas. This is a kind of green technology.

Inquiry Guides

Dear Customer: :-)

Good day.

When you are going to send us a inquiry, in order to design the most appropriate machine for your project, please answer the following questions in your letter:

1. What is your product, its material and application

2. What is the possible max. dimension of your product

3. What is your desired productivity per 8 hours/shift.

The answers to the above question will help us a lot on designing or do the recommendation.