| Model: | die components |

|---|---|

| Brand: | YIZE |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | press die components , die components maker , die components |

| Price: |

US $70

/ piece

|

| Min. Order: | 1 piece |

| Last Online:13 Oct, 2015 |

Dongguan Yize Mould Co.,Ltd. is a manufacturer specializing in precision automatic machine components and other precision mold parts. Our quality products are used in many fields such as precision stamping mould, plastic mould, auto mould, pharmaceutical mould and computer connector mould.

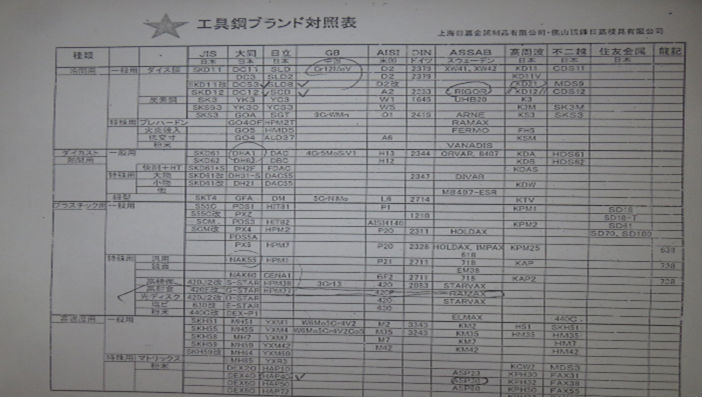

Yize adopts advanced manufacturing equipments and processing technology that from Japan.Our products mainly sold to foreign countries like Germany, United States, Japan, Italy, Israel, Singapore, Thailand and Malaysia etc.We can manufacture the products according to customers’ demands with reference to world brand as well as international industry standards like GB,JIS,DIN and AISI.Our products precision:size tolerance±0.001mm,co-axiality within 0.002, circularity 0.0015mm, surface roughness Ra0.025,linearity 300mm within 0.002. yizemold1512

| Product name | Precision press die components | |||||

| Briefly Description | 1. mold part material brand: Hatachi, Daido, ASSAB,Buderus, Bohler,etc | |||||

| 2.common material used: SKD61,SKD11,SKH51,NAK80,P20;1.2343,1.1730,1.2312;S390,K460 | ||||||

| 3.Grinding precision within 0.001.EDM/wire cut precision within 0.005mm | ||||||

| 3. milling, surface grinding, wire cutting,CNC,EDM are the main production process | ||||||

| 4.height gauge,microcalliper,profile projector,tool microscope, comparator are the main inspection equipment | ||||||

| 5.more than ten years' experience in this field | ||||||

| 6. ISO9001:2008 certified factory with good quality and management | ||||||

| 7.100% of the parts are exported to countries like Japan,USA,Europe,Southeast Aisa,etc | ||||||

| Standard | JIS AISI DIN | Usually packaging | Paper of Box | |||

| Manufacturer | Yize Mould | Yieldly | Dongguan China | |||

| Supply capability | 1000PCS/DAY | Terms of transport | express(DHL,FEDEX,TNT,UPS,etc) | |||

| Our Products | ||||||

| 1)production mode : accroding to drawings and samples to process | ||||||

| 2)material:tool steel and high speed steel,SKD61,SKD11,SKH51,etc | ||||||

| 3)technique standard : according to national standard GM, JIS,DIN,AISI ect, and other national standard to making | ||||||

| 4)4)technique advantage : grinding precision within 0.001mm, EDM/wire cut precision within 0.005mm

grinding/EDM angle clearance within R0.01. |

||||||

| 5)utilization scope : precision punch mold, precision plastic mold, precision auto mold, precision medical mold, precision computer connector mold and other factory automation part etc. with many areas | ||||||

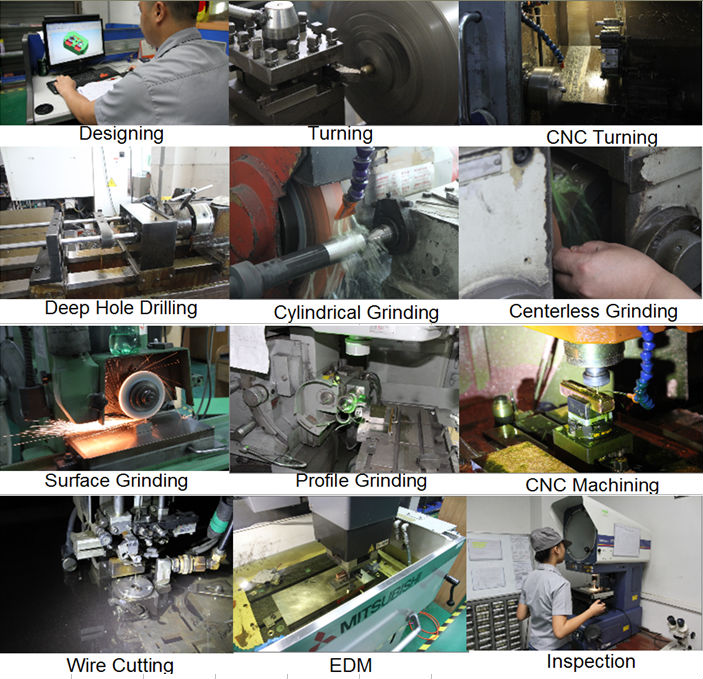

| 6)production equipment :Two sets of milling machines, two sets of CNC lathe, two sets of cylindrical grinders,one deep hole drilling machine,30 sets of surface grinders,12 sets of EDM machine,2 sets of CNC machine,4 sets of wire cut machine | ||||||

| 7)product accuracy : diamension tolerance +-0.001mm, axiality within 0.002mm,roundness within 0.0015mm, surface roughness within Ra0.025, straightness within 0.002 | ||||||

| 8)packaging type : inner package with recycle plastic box after anticorrosive oil spraying,out package with sponge and PE bag. | ||||||

| 9)cooperation customer : Japan,USA,Europe,Southeast Aisa,etc | ||||||

Material Type:

connector mould part -samples

Production Flow

30 sets of grinding machine and skilled workers enables us to make large quantity mould parts with high precision in a short time.Our grinding precision can be within 0.001mm.For stack tolerance,like 100 pieces,we could ensure tolerance within 0.01mm.We supply to worldleaders like TE,JAE,JST,etc.

We have 4 sets of sodick wire EDM machines, it ensures general tolerance within 0.005mm, flatness,verticality,and linearity within 0.002mm.The smallest wire we use is 0.1mm.

We have two CNC machines that are mainly used to make the electrodes. Copper and Tungsten copper are the main material. Our designers design the electrode and the CNC department makes it out in house. It greatly ensures EDM quality and fast delivery

4 sets of Mitsubishi EDM machines and 10 sets of other brand EDM mahines make us possible to ensure EDM precision within 0.005mm.For some parts that need special smoothness even mirror surface,we could handle with the mitsubishi EDM machines,which ensures Ra0.15.

Company Information

Dongguan Yize Mould Co.,Ltd. is a manufacturer specializing in producing precision mould parts for 8 years. Our quality products are used in many fields such as precision connector mould, plastic mould, punch mould, stamping mould, die casting mould,machinery,etc.The advanced technology and high quality service have obtained us a good reputation from customers at home and abroad.

Yize adopts advanced manufacturing equipments and processing technology that from Japan.Our products are 100% exported, mainly Japan, United States, Southeast Aisa and Europe. We mainly make nonstandard parts as per drawing or supplied Grinding tolerance within 0.001mm,EDM and wire cut precision within 0.005mm,axiality within 0.002, circularity 0.0015mm, surface roughness Ra0.025,linearity 300mm within 0.002 are the production precision available.

We passed the ISO 9001:2008 on 2013,it is a great honor and result of our long term focus on this field.

Factory Show

Surface grinding room

Skilled workers make perfect parts

EDM machining room

Advanced equipment ensures great work

Insepection room

Our inspection equpments are imported from Japan,Switerland,etc,greatly ensure the accurate inspection.All our parts are 100% inspected before shipment.Good quality wins good reputation.Our parts are recognized all over the world

Customer visit

Cutomer from Japan Cutomer form the USA

Our Services

Turning, CNC turning, milling,deep hole drilling,cylindrical grinding,enterless grinding,surface grinding, wire cutting,CNC,profile grinding, EDM machining are the in-house service offered.Also polishing,laser marking,electroplating are available for us by outsource supplier.

Packaging & Shipping

Turning, CNC turning, milling,deep hole drilling,cylindrical grinding,enterless grinding,surface grinding, wire cutting,CNC,profile grinding, EDM machining are the in-house service offered.Also polishing,laser marking,electroplating are available for us by outsource supplier

TEL: +86-769-81888522

FAX: +86-769-81888548

Email: jack@dgyize.com

Web: http://www.yizemoulds.com/