| Model: | YG-XPSXT2000 |

|---|---|

| Brand: | Sunshine |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | xps cornice machine , polystyrene cornice , cornice machine |

| Price: |

US $200000

/ set

|

| Min. Order: | 1 set |

| Live Chat: | Last Online:23 Jun, 2016 |

Model: YG-XPSXT1000S YG-XPSXT2000D

Invention Patent Of The extrusion line for cornices

FAQ

Question1.How many meters produce per minute of the xps cornice machine?

Answer :Different densign and size ,the capacity is different ,for 45mm width cornice ,about 15-20meters per minute ,for 58mm width cornice ,about 12-15 meters per minute ,for 130mm width cornice ,about 6-8 meters per minutes.

Question2.How many people need for the whole production line ?

Answer :2-3 workers needed for the whole line ,the main production processes are feeding material and packing .

Question3.How many densign could be produce with this machine ?

Answer :You could produce any densign your market required just by changing different mould .

Question4.How long will it take to change the mould ?

Answer :It need about 20-30minutes to change the mould ,it is very easy .

Question5.Which foaming agent (gas)could be used in this line ?CO2?How many gas used ?

Answer :Butane or freon (if nessary liquid gas used in cooking is also ok ).For Co2 technology ,it is also under development,it will be succeed in the near future.It will use d about 3%-4%

Question6.What's the density of the cornice this machine produced ?

Answer :From 40KG-100KG per stere .The normal density is 50-80KG per stere.

Question7.What‘s the raw material ?

Answer :GPPS (General Purpose Polystyrene)and HIPS (High Impact Polystyrene)

Question8.Whether the cornice could be antiflaming or not ? Whether the cornice could be antioxidant or not ?

Yes !It could be antiflaming and antioxidant by mixed special material

Question 9.Do you have and supply the raw material ?If not ,could you find the raw material for us ?

Yes,we could find material supplier for you ,for the whole production line ,it need about 1x40GP container for shipping ,and we could take some material for you ,about 2 to 3Tons .

Question 10.How about the shipping ,packing and payment ?

Answer :It need about 1x40GP container ,standard seaworthy packing .The payment is by TT .

The extrusion line for cornices

Functions

Technical Parameters

|

Model |

YG-XPSXT1000S |

YG-XPSXT2000D |

|

Main material |

GPPS |

GPPS |

|

Foaming agent |

Butane/Freon |

Butane/Freon |

|

Extruder |

Single |

Double |

|

Capacity |

40-60KG/Hour |

70-90kg/Hour |

|

Product thickness |

4-12mm |

4-15mm |

|

Products width |

30-140MM |

40-160mm |

|

Products density |

30-100KG/M3 |

30-100KG/M3 |

|

Cooling |

Water/wind |

Water/wind |

|

Installation power |

60kw |

115kw |

|

Consumption power |

20kw |

35kw |

|

Power supply |

3 Phase 4 lines |

3 Phase 4 lines |

|

Installation size |

25X4.5X3.2M |

28X6.5X3.2M |

|

Weight |

11T |

13T |

|

Plant area (at least) |

200-300M2 |

200-300M2 |

The extrusion line for cornices

Production Video

http://youtu.be/nCzZ994kSM8

http://youtu.be/EIefewxvEd4

http://youtu.be/sSmndXdHSDk

Installation video

http://youtu.be/eqqkx80WNb8

The extrusion line for cornices

Technology

The extrusion line for XPS cornices is designed to produce, through a process of hot extrusion special extruded polystyrene foam profiles. This process is characterized mainly by the continuous mixing of a blowing agent in melted polymer. The compound of the various components is prepared in a mixer and pneumatically transported to a dosing device, which feed the mixture into the extruder. In the extruder the mixture is heated to the melting temperature of polystyrene. The profile polystyrene cornice will be extruded from the die head after the mixture and the foam agent mixed enough .

Machine real scene

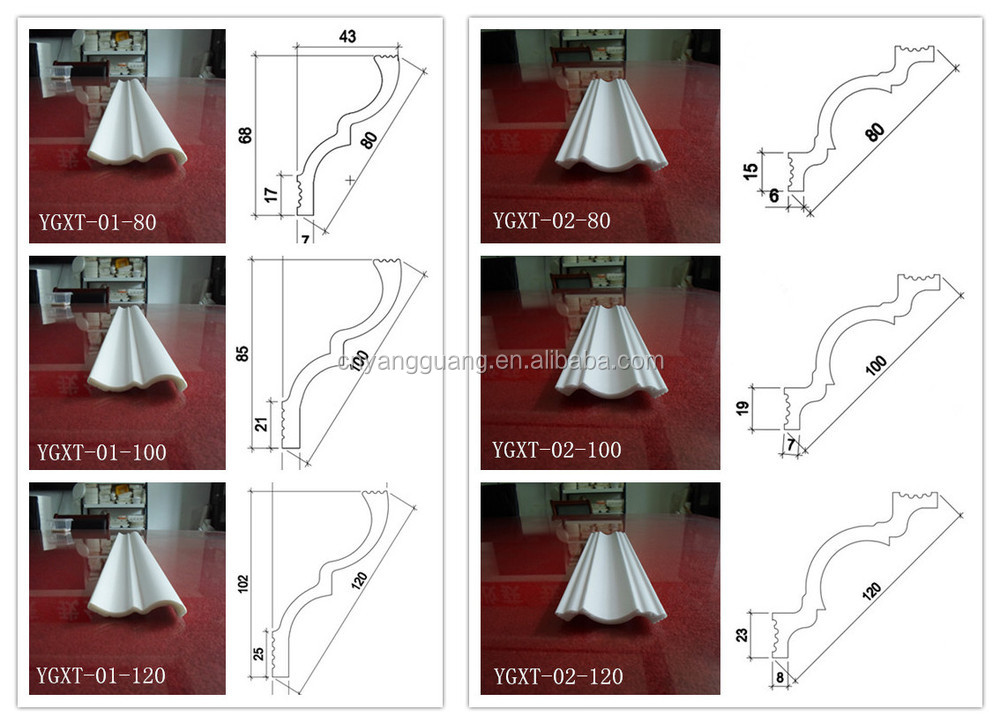

Polystyrene Interior Room Decorative Crown Mouldings Machine

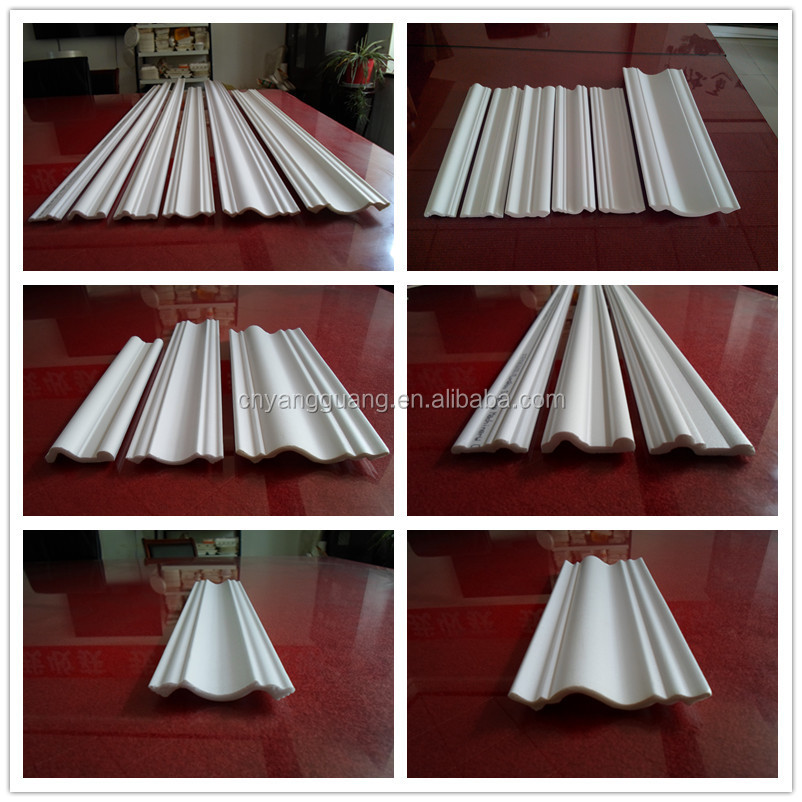

Finished Products

The extrusion line for cornices

Packaging & Shipping

|

Packaging |

Standard Export Package |

|

Delivery Time |

60 days after deposit |

The extrusion line for cornices

Contact Infor

Contact :Daisy cai

Mobile /Wechat:0086-15275520178

Whatsapp:0086-15275520718

Skype:daisycai01

QQ:1760148974