| Model: | DMZ |

|---|---|

| Brand: | Xingnuo |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Other Electrical & Electronic |

| Label: | concrete pole machin |

| Price: |

US $100000

/ set

|

| Min. Order: | 1 set |

| Live Chat: | Last Online:15 Oct, 2015 |

Company Information

About"Zhejiang Xingnuo Machinery Co., Ltd."

Xingnuo Machinery is a Chinese supplier and manufacturer producing Concrete pole machines/Concrete pipe machines; the equipments and moulds meet the national standards and can be customized according to the standards of the world; Our products have spread all over Africa, Middle Asia, Southeast Asian countries.

Product Description

The standard of Kenya prestressed concrete poles

Mainly Equipment

1. Prestressed concrete pole spinning machine

Centrifugal spinning machine for prestressed spun concrete electrical pole is a kind of mold equipment, which is used for producing reinforced concrete poles and other cement products with a variety of different diameter and length.

Because the production principle of prestressed spun concrete electrical pole is the centrifugal fabrication, the centrifugal spinning machine became one of the most important equipment of concrete poles manufacturing.

Centrifugal spinning machine comprises base, supporting wheel, bearing base, control cabinet and driving shaft. It should be worked with the concrete spun pole mold. Concrete pole centrifugal machine forming mode is low speed-medium speed-high speed.

1) Low speed: when the slumps of the cement is lower than 6cm, and the rotation speed is 100rpm~120rpm, spin for 1.5min~2min.

2) Medium speed: mainly for preventing the devices and products from impact and vibration, at the same time make sure that the redundant water is drained slowly and the cement become dense, spin for about 1.5min~2min.

3) High speed: forming speed of the rotation process, guarantee that the redundant water is drained under fully centrifugal force, and make sure that the right external rotating speed is not less than 360rpm, spinning time is 7min~8min.

Usually, the diameter of riding wheel of the centrifugal spinning machine is 600mm, and the diameter of the shaft is 130mm. The distance of two riding wheels is 2m. So, the number of the sets of centrifugal machine depends on the length of poles.

The material of riding wheels of spinning machines is casting steel. It can prolong the service life of our centrifugal spinning machines. So we can promise that our spinning machines’ quality is better than others.

The power requirement of our centrifugal spinning machine is 380 volt alternating current, 50 hertz. The maximum sinning speed is 900 rpm. The diameter of riding wheels is 600mm, and the dimension of our spinning machine is 1500mm multiplied by450mm multiplied by 7500mm. These parameters are according to the national standards. You can safely use.

All the facts can show you that our products are of high quality.

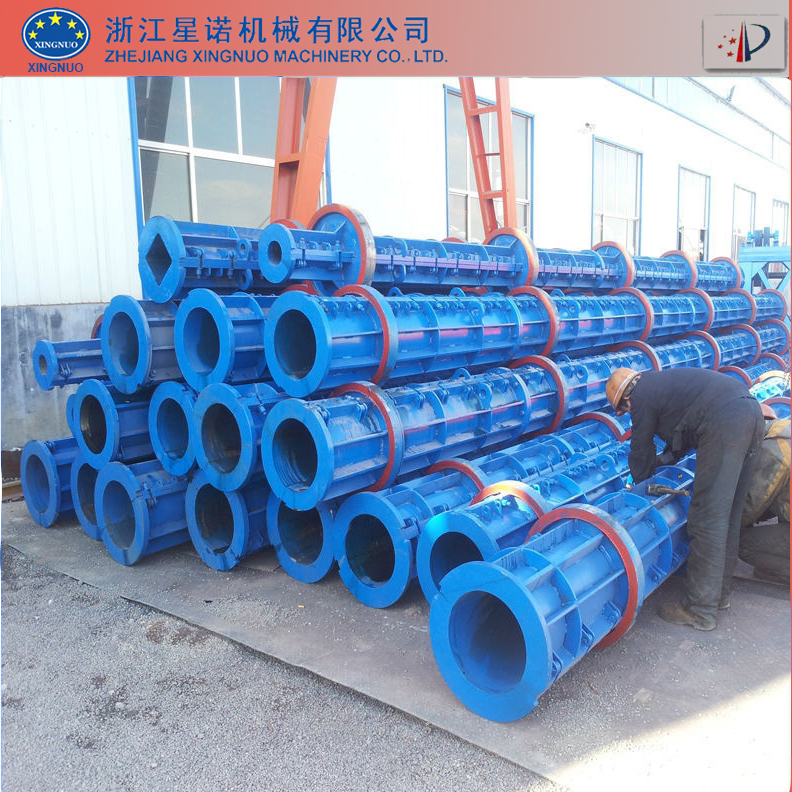

2. Concrete pole steel mold

Our Prestressed Concrete Spun Pole Mold is used for concrete electrical pole manufacturing. It’s mainly manufacture technology is longitudinal tension by steel wires. Then it can squeeze out the excess water in the concrete under the centrifugal force. Thus, it can greatly improve the concrete density and strength.

The prestressed concrete spun pole mold is an essential equipment of electrical pole manufacturing.

There are two fabrication method of molds: wholly processing and processing in segments. The cost of wholly processing is lower than processing in segments. And the quality of wholly processing mold is better than processing in segments mold. We have a process mold 18m lathe, so generally, we can produce the molds in wholly processing.

Concrete pole mold is semi-circular double-segment structure. In order to open and close the mold more conveniently, the steel mold is designed and produced by upper and lower molds combining together. And the joint of molds used the flush joint. That way can efficiently prevent concrete leak out of mold.

There are three features of prestressed spun concrete pole molds. The first one is welding technology, which enhances the smooth finish of the mold wall, and eliminates the uneven traces of rivet holes. So the concrete poles appearance will be improved significantly. The second one is the cylinder is changed to U-type longitudinal stiffeners, which can greatly increase the stiffness and flexural strength of the steel mold. The last one is all the molds are installed with the slot with rubber sealing strip, in order to prevent leakage to ensure quality. All these three features can ensure the quality of concrete poles.

The body of molds, longitudinal bar, wind wire and flange plate make up the pole molds. Except the body of molds, the other three parts of pole molds are made by number 45 casting steel. And we use the welding process to weld the running wheel of molds. The material of running wheel also used the 45# casting steel. So, our molds are very solid.

The thickness of running wheels decide how long that you can use the molds. Usually, it is 30mm. We promise that we product our molds as per national standards.

All of the facts of our pole molds can prove that our products must be your best choice.

3. Related Machines

We can also offer these related machines to our customers.

FAQ

1. Specifications of Concrete Poles:Length,Top Diameter,Bottom Diameter.

2. Type of concrete Pole:Pre-stressed or Reinforced .

3. Daily or Annual Productivity.

Our Services

1.Complete production line supporting machines and all necessary accessories with high performance and good quality;

2. Free Service of plant structure design and layout plan drawings and other necessary construction drawings and guidance of construction work,office, warehouse etc and related drawings according to customers’ requirements.

3.Installation and commissioning of all production machines as well as the workers training.

We promise our customers:

High Qaulity ,

Professional Guidance

Satisfactory After-Sale Service!

Warmly Welcome To Visit Our Factory !

If you are interested, please don't hesitate to contact me at any time