| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Construction & Decoration / Other Construction Materials |

| Label: | anti corrosion pile |

| Price: |

US $100000

/ set

|

| Min. Order: | 1 set |

| Live Chat: | Last Online:15 Oct, 2015 |

Company Information

Zhejiang Xingnuo is a professional company design and fabricate concrete pile steel mold and related auxiliary equipment. The company was established in 2008. Our company covers an area of 10000 square meters with more than 150 employees. Technical and administrative staff about 150 people. Engineers more titles about 10 people. Strong technical force, excellent production equipment, four double housing planer, four large lathe .And other large equipment more than 30 pieces. Our company adopted gas welding protection. Steel molds tongue-and-groove using planer finishing.Tongue-and-groove dense, not easy to leak slurry. There are four production lines, daily productive of the mold more than 100 meters.

Product Description

1. 1. Overview of Anti-corrosion prestressed concrete piles

1. 1. Overview of Anti-corrosion prestressed concrete piles

Anti-corrosion prestressed concrete piles is used for construction platform pile foundation of corrosive geology areas.

GB50046-2008 Industrial building anticorrosion design specification specifies the corrosive grading:

(1) Corrosive medium according to its existing form can be divided into gaseous, liquid, and solid medium, a variety of media should be divided into categories according to its content and environmental conditions.

(2) According to all kinds of medium of building materials under the action of corrosion for a long time, can be divided into strong corrosion, middle corrosion, weak corrosion and micro corrosion.

2. Stipulations of Anti prestressed concrete piles foundation

The choice of pile foundation should meet the following requirements:

(1) Choose precast reinforced concrete piles under corrosion environment;

(2) When corrosion grade is middle or weak corrosion, prestressed concrete piles or bored concrete piles can be used.

(3) Reduce the number of precast concrete piles. Joints should be located in the contaminated soil.

(4) When pile caps buried shallow, medium of production will corrode piles body. And piles may be in a dry-wet alternate and freeze-thaw action strong environment. So buried depth more than 2.5 piles should be strengthen the protection measures.

3. Protection of concrete pile body

|

Types of piles foundation |

Protection measures |

Corrosive grade |

||||||||

|

SO |

CL— |

PH value |

||||||||

|

Strong |

Middle |

Weak |

Strong |

Middle |

Weak |

Strong |

Middle |

Weak |

||

|

Precast reinforced concrete pile |

Improve corrosion resistance of pile body concrete. |

Using sulfate resistance portland cement, add admixture of resistance to sulfate and mineral admixtures. |

Don’t protect

|

Add corrosion inhibiting admixtures and mineral admixtures. |

Don’t protect. |

— |

— |

Don’t protect. |

||

|

Increase the concrete corrosion allowance. (mm) |

≥30 |

≥20 |

— |

— |

≥30 |

≥20 |

||||

|

Brush anti corrosive coating on surface. (mm) |

TH ≥500 |

TH ≥300 |

TH ≥500 |

TH ≥300 |

TH ≥500 |

TH ≥300 |

||||

|

Prestressed concrete piles |

Improve corrosion resistance of pile body concrete. |

This type of piles should not be used. |

Using sulfate resistance portland cement, add admixture of resistance to sulfate and mineral admixtures. |

Don’t protect. |

This type of piles should not be used. |

Add corrosion inhibiting admixture and mineral admixture. |

Don’t protect. |

This type of piles should not be used. |

— |

Don’t protect. |

|

Brush anti corrosive coating on surface. (mm) |

TH ≥300 |

TH ≥300 |

TH ≥300 |

|||||||

|

Bored concrete piles |

Improve corrosion resistance of pile body concrete. |

Using sulfate resistance portland cement, add admixture of resistance to sulfate and mineral admixtures. |

|

Add corrosion inhibiting admixtures and mineral admixtures. |

— |

— |

||||

|

Increase the concrete corrosion allowance. (mm) |

≥40 |

≥20 |

— |

— |

≥40 |

≥20 |

||||

4. Measurements of pile‘s anti-corrosion

(1) Anticorrosion concrete pile is produced by prestressed tensioning, centrifugal molding and secondary curing process. And it is mixed ground fine quartz sand, S95 and superfine slag powder and other admixtures.

(2) Through adding naphthalene series high efficient water reducing agent, make concrete between dry concrete and plastic concrete. Concrete of piles’ strength reaches to C80. It has high corrosion resistance.

(3) Increase the protective layer thickness to increase the concrete corrosion allowance.

(4) Adding rust resistance composite concrete preservatives. It is used for strong corrosive geology.

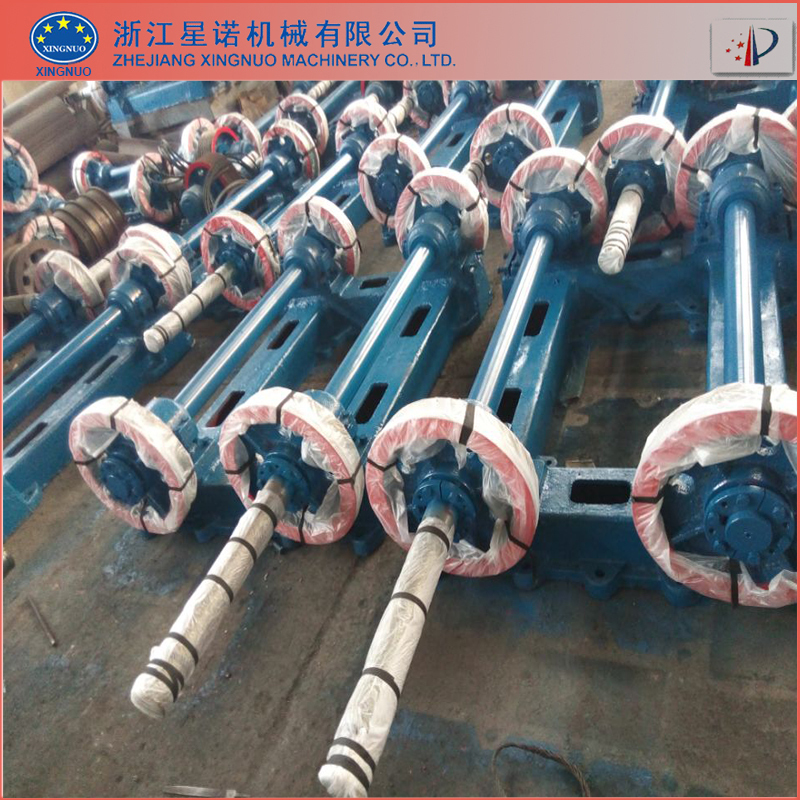

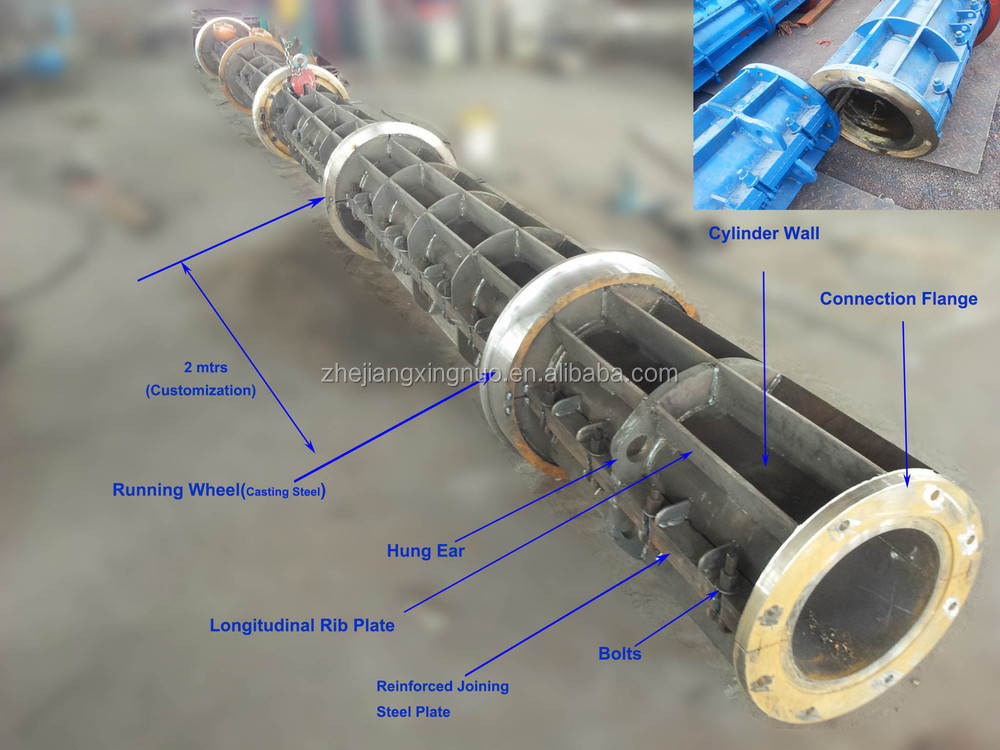

Concrete pile Centrifugal spinning machine

1. Overview of Heavy Concrete Spun Pile Spinning Machine

Centrifugal spinning machine for prestressed spun concrete pile is a kind of mold equipment, which is a mainly forming equipment used for producing circular prestressed concrete piles, square prestressed concrete piles and other cement products with a variety of different diameter and length.

Centrifugal spinning machine for prestressed spun concrete pile is operated by remote-controlled continuously variable motor. It runs smoothly and has a variable-speed range. So the production of concrete piles are good of quality.

The base of the machine is welded in box-type structure, sturdiness and durability. The bearings are well sealed and reliable, long service. Random electric control equipment is complete and easy to operate.

2. Working Principle of Heavy Concrete Pile Spinning Machine

1) Spun pile mold rotates with Centrifuge, there are longitude stiffeners and latitude stiffeners around the surface.

2) The redundant water in the concrete is released under the force of centrifuge and concrete gets dense and high strength.

3) Spun pile spinning machine operates together with Pre-stressed concrete pile steel mold.

4) Under the motor-driven, the slurry is divided into two-tier under the action of centrifugal force.

5) The heavier solids deposited on the inner wall to form sediment layer, while the lighter liquid is separated from the formation of the inner fluid layer.

6) The Sediment is released after dehydration, while the fluid is released.

3. Features of Heavy Concrete Spun Pile Spinning Machine

(1) Saving a great deal of steel, about 30~70% (employ cold-drawn steel wire can save 30%~60%; employ high stress steel wire can save 40%~69%).

(2) Crack resistance can increase by about 3~5 times.

(3) Rigidity increases 1~3 times.

(4) Reducing the cost (using cold drawn steel wire can reduce 25%~40%; using high stress steel wire can reduce 12%~21%).

(5) Good durability, can delay the existence and expansion of cracks.

(6) Protect the environment on which human beings depend on for existence, and reduce the deforestation.

4. Parameters of Heavy Concrete Spun Pile Spinning Machine

|

No. |

Item |

Unit |

Type and Combining form |

|

|

Φ300-Φ600 |

Φ500-800 |

|||

|

1 |

Riding wheel distance |

MM |

2000 |

2000 |

|

2 |

Shaft distance of riding wheel |

MM |

950 |

1050 |

|

3 |

Outer diameter of riding wheel |

MM |

600 |

600 |

|

4 |

Width of riding wheel. |

MM |

80 |

80 |

|

5 |

Included angle α between center of riding wheel and steel mold center cable |

(°) |

75°-110 |

|

|

6 |

Forming pile’s maximum length |

M |

15 |

15 |

|

7 |

Transmission shaft diameter |

MM |

Φ110 |

Φ125 |

|

|

|

|||

|

8 |

Motor power |

KW |

55 |

75 |

|

9 |

Main transmission shaft speed range |

r/min |

75-500 |

75-500 |

Concrete pile steel mould

1. Overview of Prestressed Concrete Spun Pile Mold

Prestressed Concrete Spun Pile Mold is used for prestressed concrete pile production. Its mainly manufacture technology is longitudinal tension by steel wires. Then it can squeeze out the excess water in the concrete with centrifugal force. Thus, it can greatly improve the concrete density and strength.

In order to form the concrete more quickly to meet the design strength of more than 70%, steam curing can be carried out so as to shorten the mold-releasing cycle.

We have two categories of prestressed spun concrete pile molds: circular concrete pile steel mold and square concrete pile steel mold.

2. Features of Prestressed Concrete Pile Mold

2.1 Welding technology, which enhances the smooth finish of the mold wall, and eliminates the uneven traces of rivet holes. So the concrete poles appearance will be improved significantly.

2.2 The cylinder is changed to U-type longitudinal stiffeners which can greatly increase the stiffness and flexural strength of the steel mold.

2.3 Install the slot with rubber sealing strip, in order to prevent leakage to ensure quality.

3. Working Principle of Prestressed Concrete Pile Mold

3.1 The steel mold should work together with heavy prestressed pile centrifugal spinning machine. The steel mold should be placed on the spinning machine smoothly.

3.2 Put the mixed slurry into the mold and rotate in different directions under the motor driven.

3.3 In this process, the redundant water in the concrete is released by the force of centrifugal, and the concrete is dense and high strength. And then, the pole forms around the inner wall of the concrete pile mold.

The concrete pile machine pics show:

Concrete pile toe

Related products

Production process

FAQ

1. Specifications of Concrete pile :Length, Diameter, Grade and PC bar

2. Type of concrete Pile :Pre-stressed or Reinforced .

3. Daily or Annual Productivity.

Our Services

1.Complete production line supporting machines and all necessary accessories with high performance and good quality;

2. Free Service of plant structure design and layout plan drawings and other necessary construction drawings and guidance of construction work,office, warehouse etc and related drawings according to customers’ requirements.

3.Installation and commissioning of all production machines as well as the workers training.

We promise our customers

High Qaulity ,

Professional Guidance,

Satisfactory After-Sale Service!

Warmly Welcome To Visit Our Factory !