| Model: | 25H |

|---|---|

| Brand: | HD |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Engraving & Etching Machine |

| Label: | CNC Router , Woodworking Machine , Wood CNC Router |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:24 Jul, 2013 |

In-Line ATC CNC Woodworking Machine Technical-parameters:

|

Performance |

Parameter |

Optional |

|

|

Stroke range |

X axis |

1300mm |

1500mm/2000mm |

|

Y axis |

2500mm |

2500mm/3000mm/4000mm |

|

|

Z axis |

250mm |

||

|

Process precision |

+-0.1mm |

||

|

Reposition precision |

+-0.05mm |

||

|

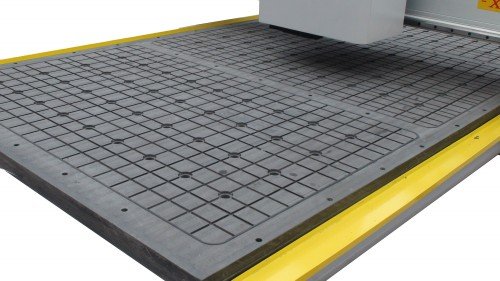

Table structure |

Vacuum suction(bar suction optional) |

||

|

X Y Z structure |

X Y gear rack, Z ball screw |

||

|

Idle speed |

>=45000mm/min |

||

|

Working speed |

>=20000mm/min |

||

|

Spindle rate |

5.5KW |

9.0KW |

|

|

Spindle speed |

0-24000rpm/min |

||

|

Motor type |

Servo motor |

||

|

Command code |

G code |

||

|

Working voltage |

AC380V/50HZ |

||

|

Operating system |

SYNTEC |

Some Parts:

New Type:

Back

Front

Whole

In-Line ATC CNC Woodworking Machine

A.Auto-Tool Changer

B.Syntec Control System

C.PMI Guide Rail

D.Vacuum adsorption table

In-Line ATC CNC Woodworking Machine Features:

A.Separate keyboard control system, easy to lean and convenient to operate, the customers are ableto master the application in a short time.

B.Intelligent anti-transgree-process protection system, this function could prevent machine crashes when the design zone is beyond the process zone. Control the process speed, so can increase the efficiency , prolong the cutter life and increase the rate if finished products.

C.Dust-suction system:the dust suction system could absorb the saw dust and keep machines clean, which maintains equipments as well; the dust suction system take place of the physical flat fixation which save the time of load and unload time of slabs.

D.Advanced file pretreatment function can correct the error in the files and is compatible with the process codes of multiple national and international software, advanced 3D space curve prediction algorithm can make sure of the evenness of polyline and the speed and precision of curve lines.

In-Line ATC CNC Woodworking Machine configuration:

1.whole steel structure , square guide rail. ballscrew for z axis, gear-wheel for x axis and y axis,

2.5KW air cooling spindle.

3.High speed servo motor and driver.

4.Vacuum adsorbtion table, and dust collector system, no oil pump. In line Auto tool changing system, Auto oiling.

SAMPLE:

In addition, we have woodworking engraver, relief engraver, cylinder craft wood engraver, special mould engraver, stone engraver, advertising machines, laser engraving/cutting machines and so on.

we can make carving machines with all specifications to meet users.